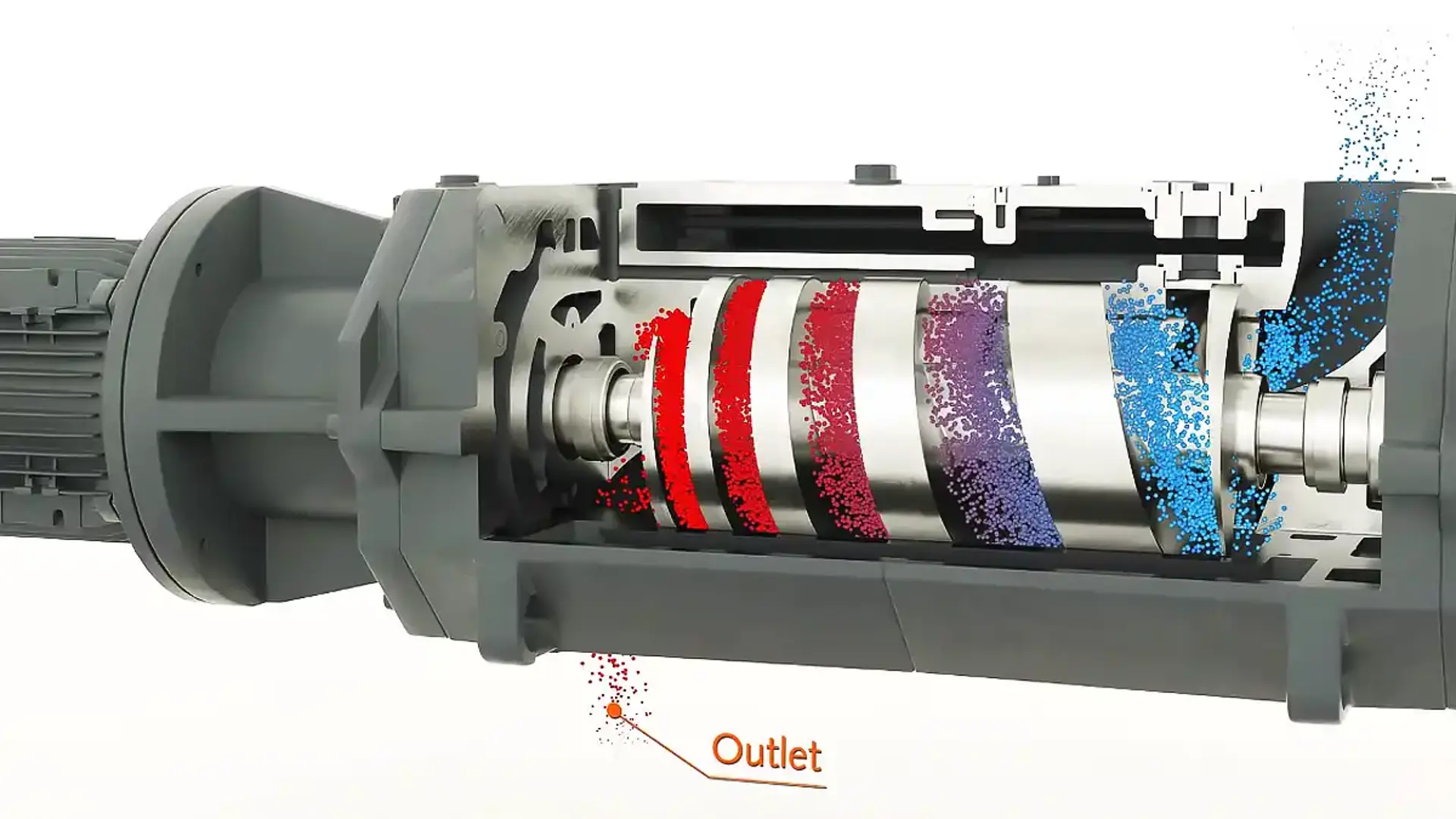

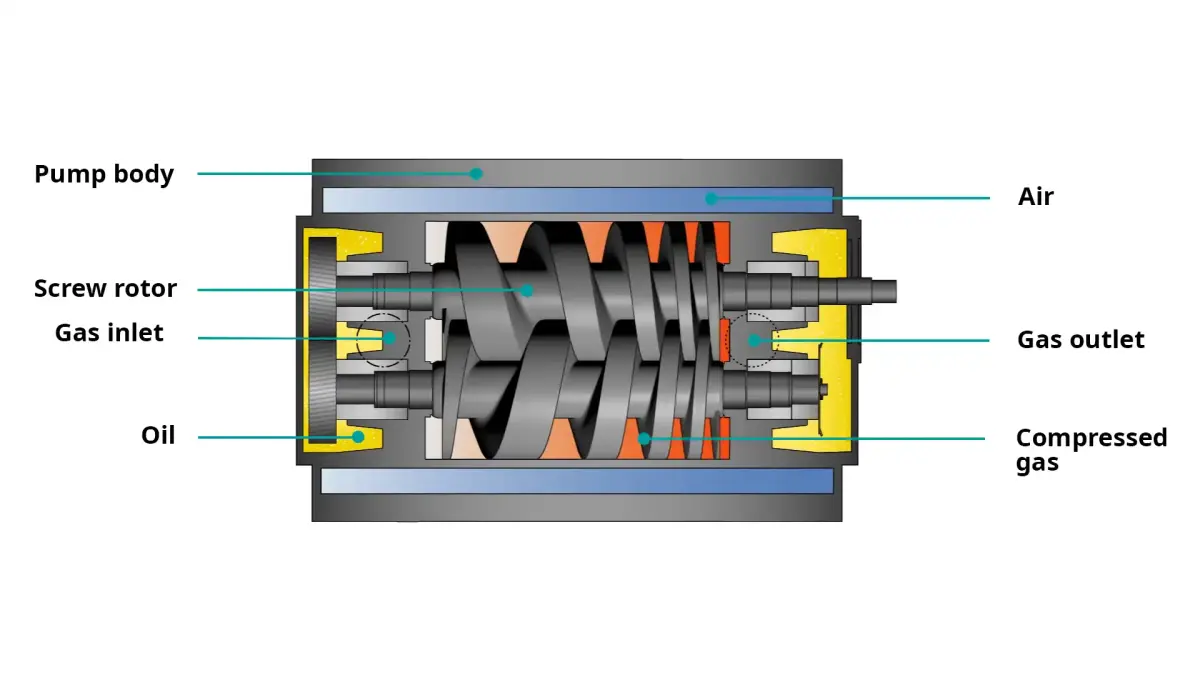

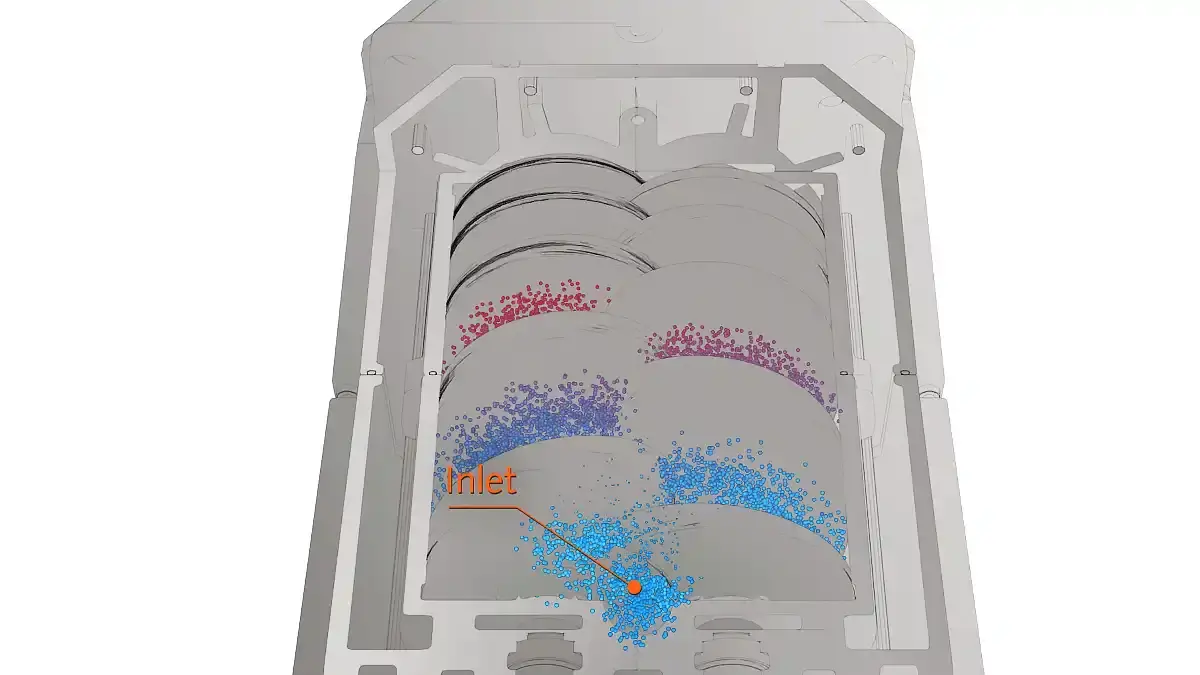

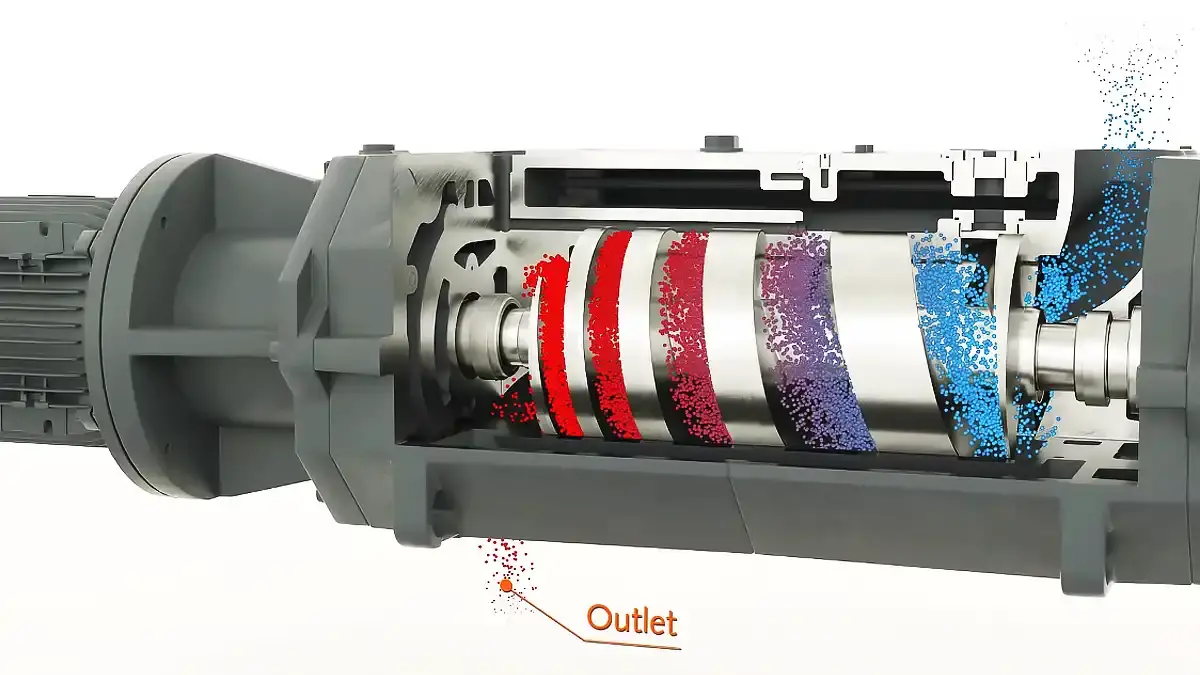

Tipos de bombas de vácuo de parafuso a seco

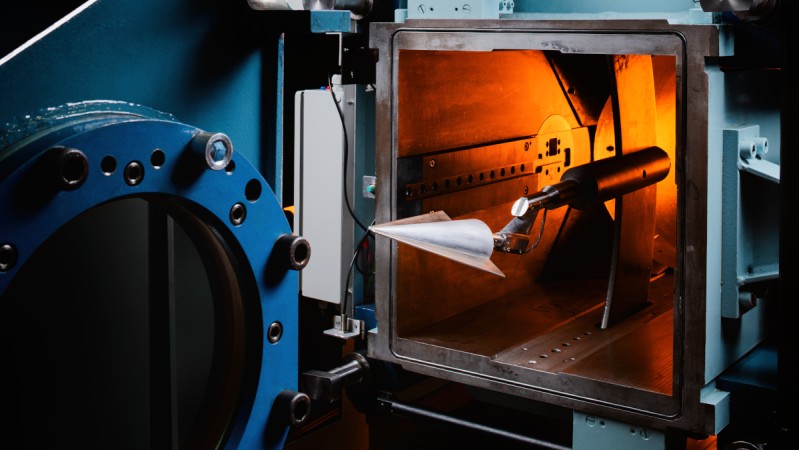

COBRA Industry são ideais para aplicações industriais, que exigem a extração livre fiável e sem contaminações de gases e vapores.Procura uma bomba de vácuo de parafuso a seco para processos exigentes, como o revestimento ou a produção de semicondutores? Explore a COBRA Semicon da Pfeiffer Vacuum+Fab Solutions (membro do Busch Group).

Série de produtos | Caudal nominal da bomba |

|---|---|

COBRA NX | 350 m³/h - 950 m³/h |

COBRA NC | 110 m³/h - 2500 m³/h |

COBRA NS | 70 m³/h - 600 m³/h |

COBRA NF | 750 m³/h - 950 m³/h |

COBRA DX PLUS | 650 m³/h - 1900 m³/h |

COBRA DS | 70 m³/h - 1640 m³/h |

COBRA DH | 2700 m³/h - 6200 m³/h |

COBRA BA | 85 m³/h - 105 m³/h |