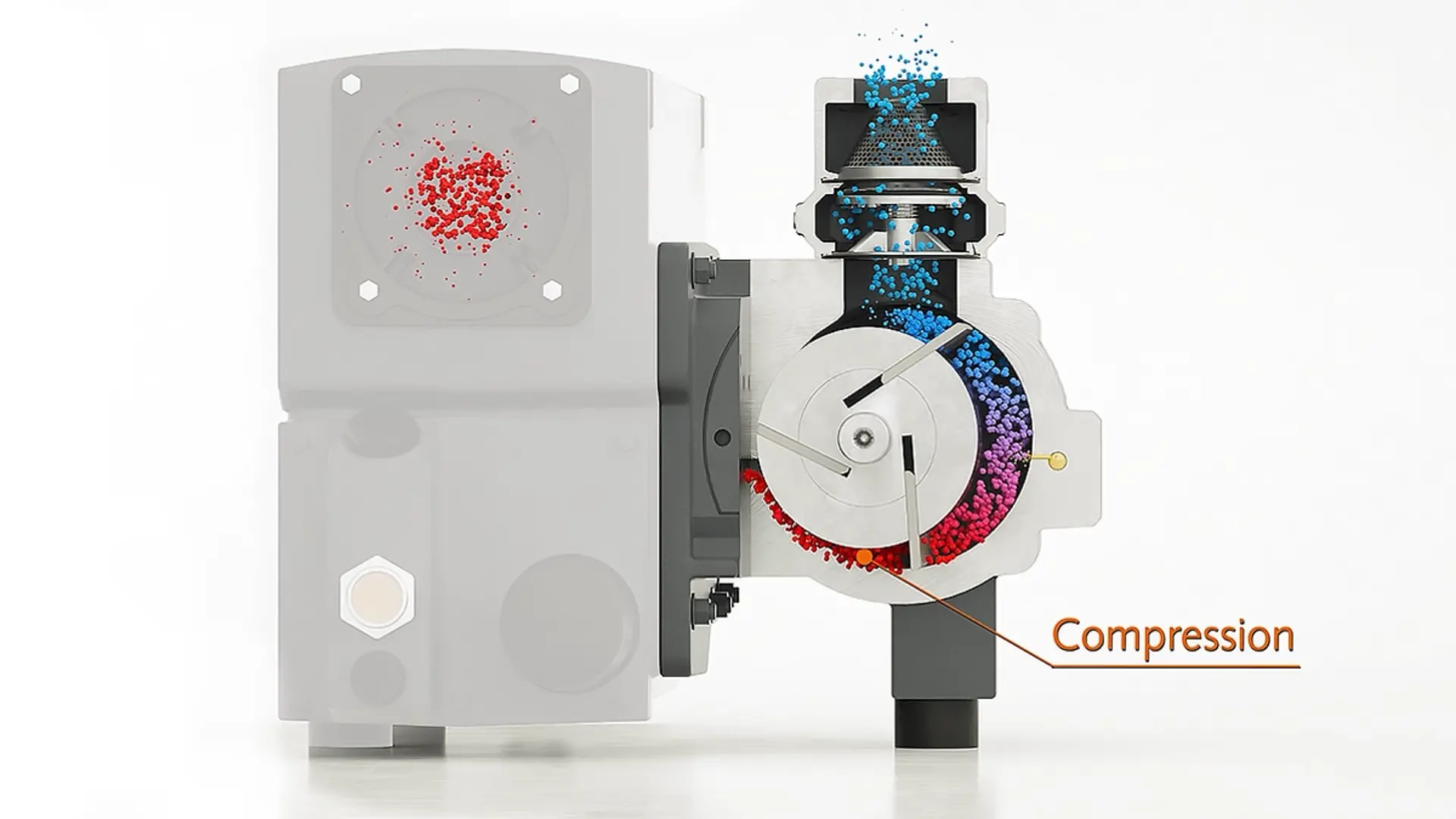

Types of rotary vane pumps and compressors

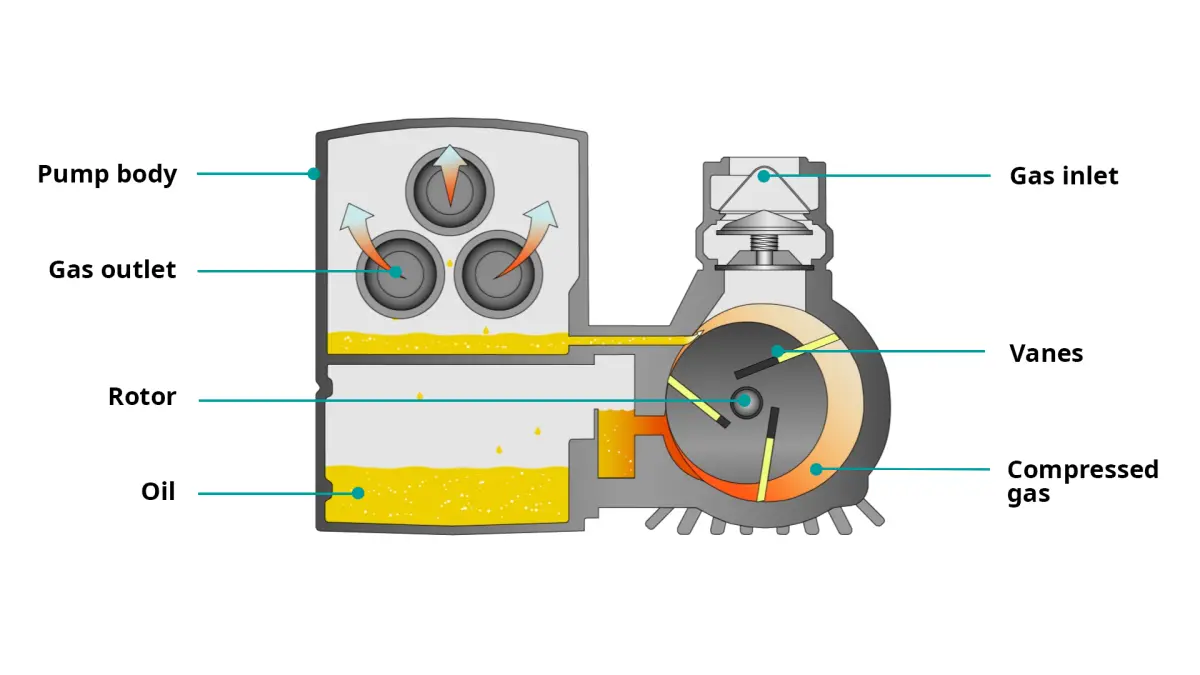

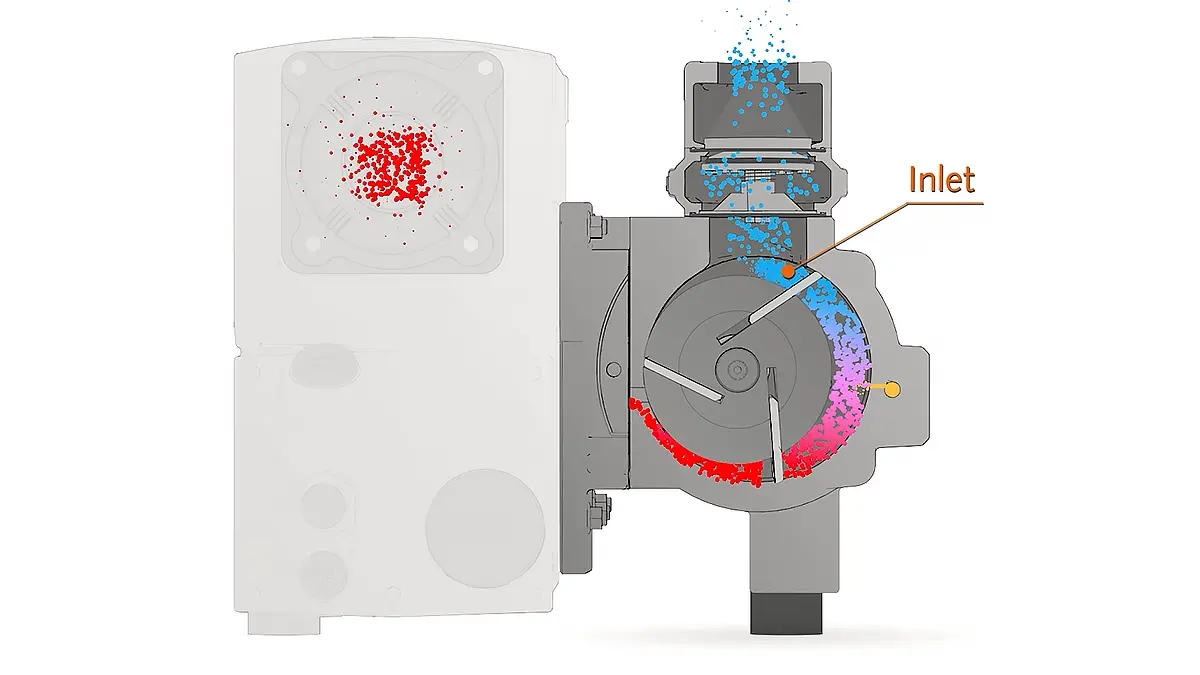

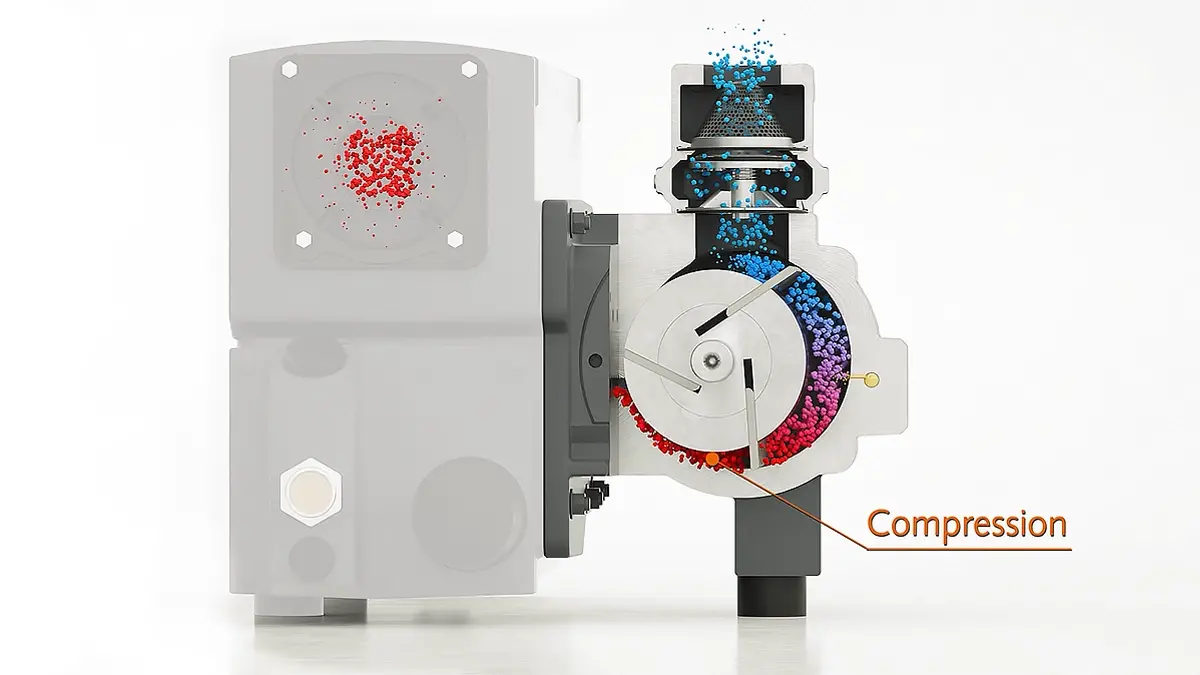

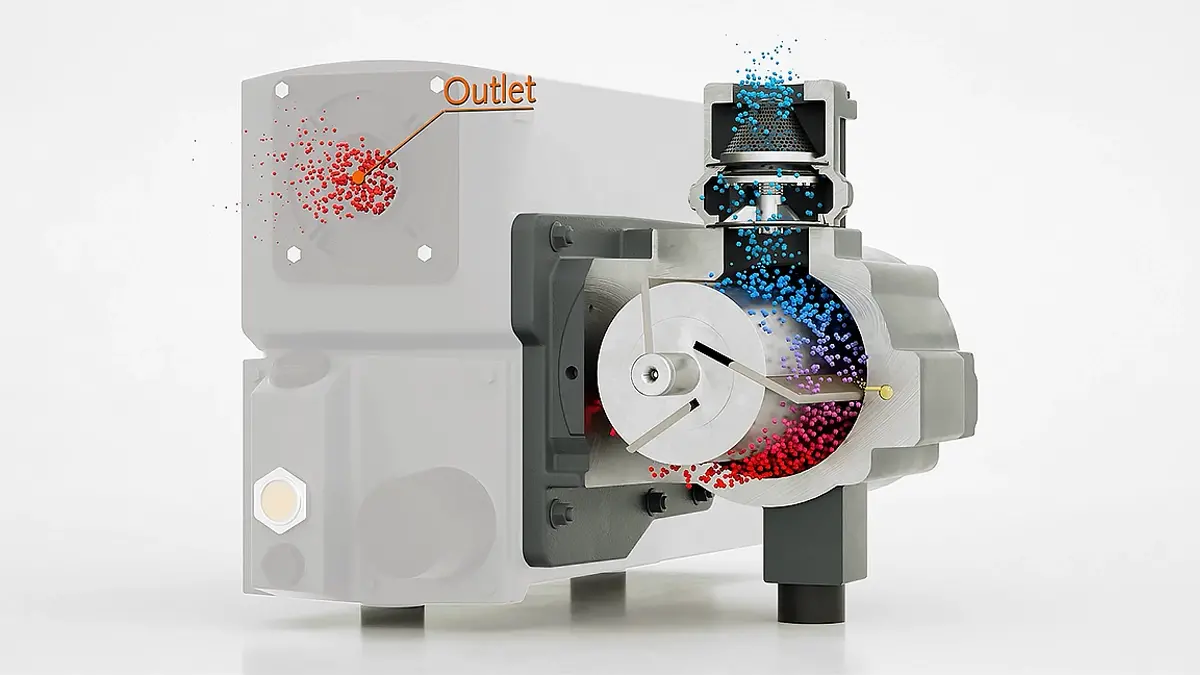

Rotary vane vacuum pumps are available in single- and two-stage versions and can be operated with different types of lubrication or dry-running. In single-stage versions, compression is carried out once. In two-stage versions, the pumped medium is compressed again in a second stage to allow for higher vacuum levels.Rotary vane compressors operate according to the same principle.

Oil helps seal the clearance between the vanes and the housing in R5 and HUCKEPACK vacuum pumps. SECO vacuum pumps and compressors use graphite dust for lubrication. This is created when the graphite vanes grind along the edge of the cylinder.

Product family | Rotary vane vacuum pump version | Oil-lubricated or dry-running | Characteristics |

|---|---|---|---|

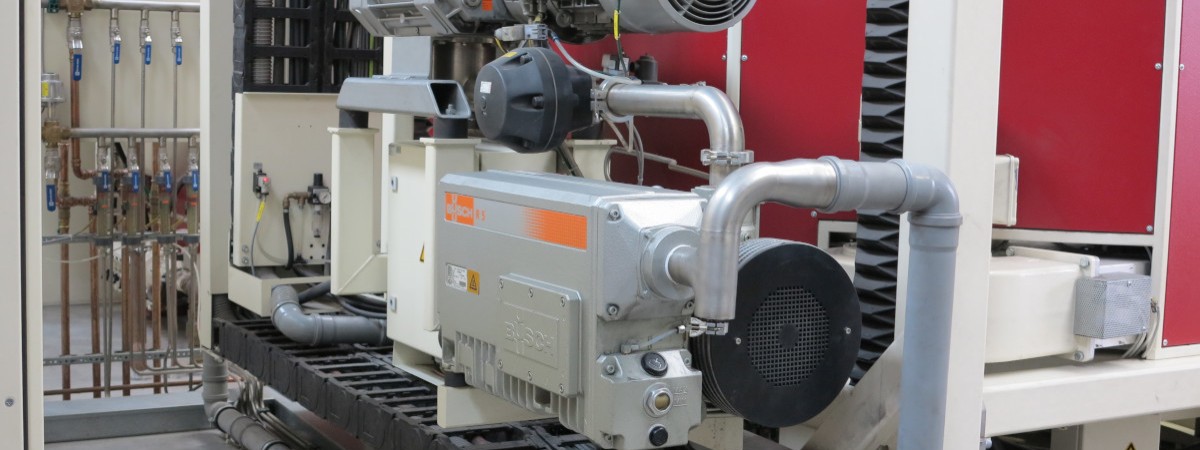

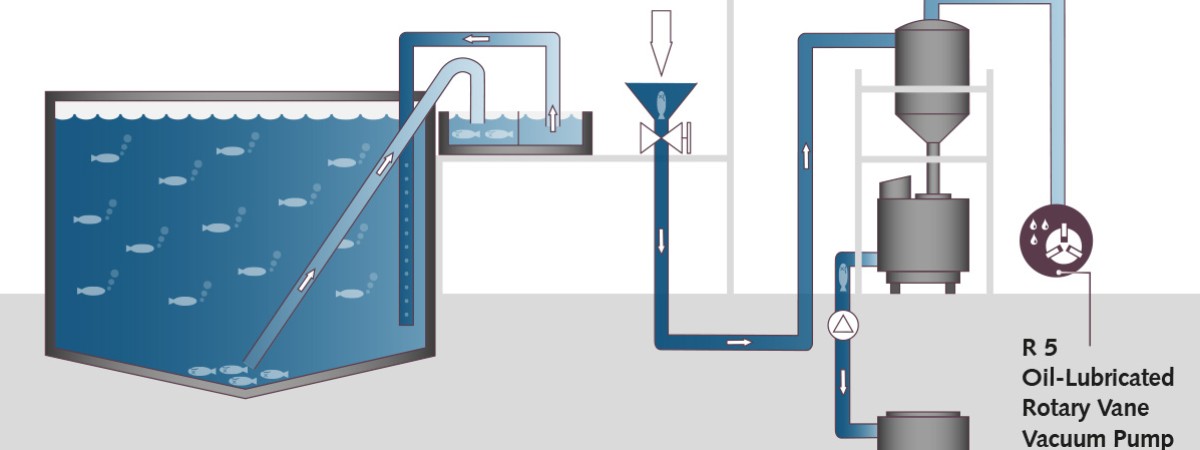

R5 | single-stage | oil-lubricated | Proven and reliable. Over 3 million pumps in operation worldwide. |

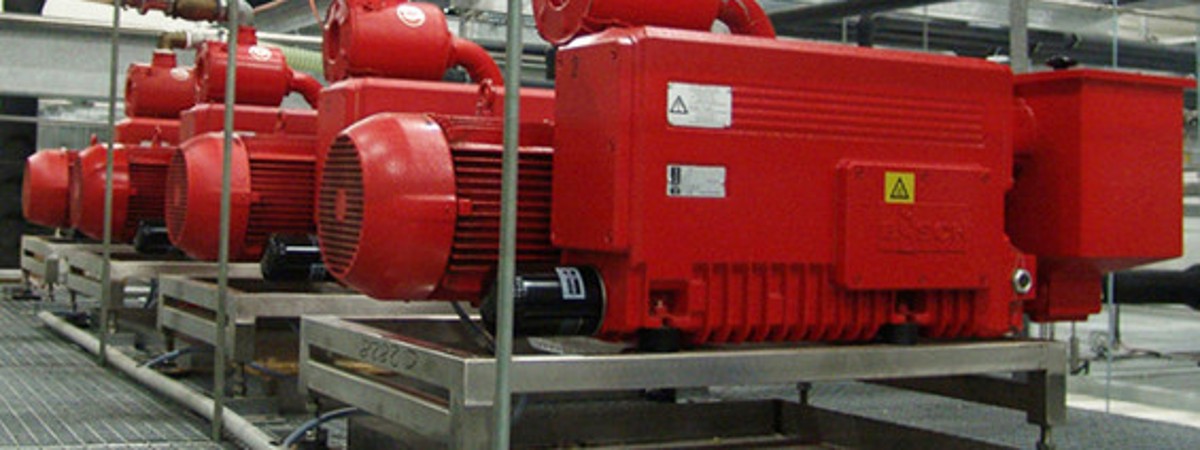

HUCKEPACK | two-stage | oil-lubricated | The robust and proven solution for difficult applications. |

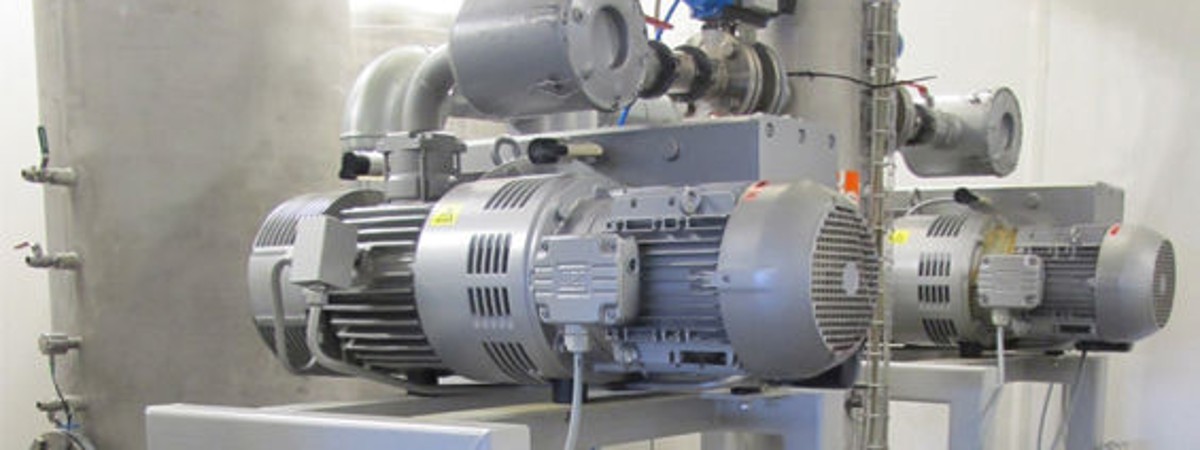

SECO | single-stage | dry-running | Reliable medium vacuum for demanding applications in industry and research. |

_about_1200x450.jpg)