Separator product lines

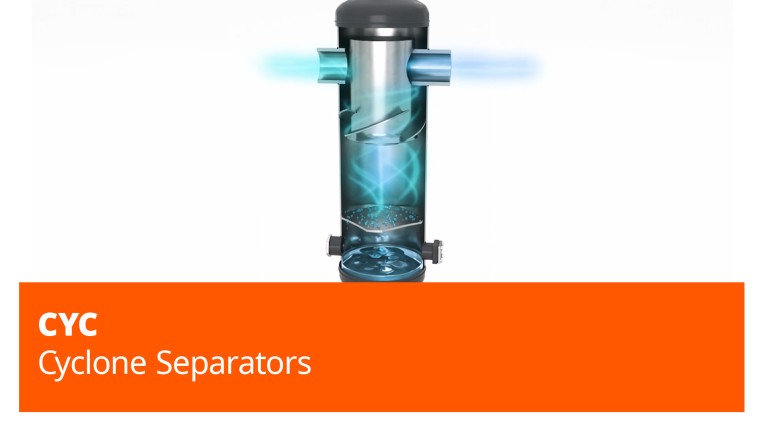

Busch provides three separator product lines: Standing filtration systems for the removal of solid particles and moderate amounts of liquid and paste, liquid separators to extract moisture and liquids from wet processes, and cyclone separators for the elimination of liquids.No matter your requirements, we have the best solution for you. Of course, always with the service tailored to your needs.

Separators from Busch can seamlessly integrate into vacuum systems. Explore our products and get in touch with our Busch experts to find the separator that fits your needs best.

Particles in the process gas | Standing filtration systems (STF) | Liquid separators (LSS / LSA) | Cyclone separators (CYC) |

|---|---|---|---|

Dust | ✓ | ||

Paste | ✓ | ||

Moisture | ✓ | ✓ | |

Liquids (small to moderate amounts) | ✓ | ✓ | ✓ |

Liquids (moderate to large amounts) | ✓ | ✓ |