- Dry-running rotary vane overpressure technology

- Reliable oil-free vacuum generation

- Robust construction

- Lifetime-lubricated bearings

- Compact dimensions

- State-of-the-art precision manufacturing

SECO

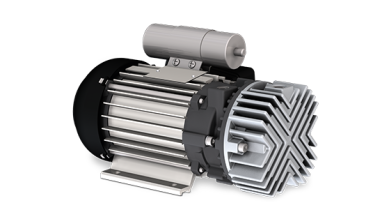

Dry-running rotary vane vacuum pumps and compressors

Compact, reliable and extremely powerful – these are the stand-out features of SECO dry-running rotary vane vacuum pumps and compressors. Due to their lubricant-free operating principle, they can be used in many industrial applications where rapid, clean vacuum or compressed air is required. The SECO family consists of vacuum pumps and compressors.

We have continuously developed and optimized our dry-running rotary vane technology for over 30 years. High levels of availability and improved performance are the benefits of this ongoing product advancement.

SECO vacuum pumps and compressors are characterized by their robust construction and lifetime-lubricated bearings.

Operating principle

Inside a cylindrical housing, a rotor with multiple vanes is mounted eccentrically. As the rotor rotates constantly, the vanes slide out and form chambers between themselves and the housing.The pumped medium is suctioned in and trapped inside these chambers. It is compressed through the ongoing rotation and transported to the outlet. Sealing is achieved by self-lubricating high-performance vanes.

SECO SD

Benefits of the SECO SD series

SECO SD dry-running rotary vane compressors are the ideal choice for any application where reliable, oil- and pulsation-free compression is required. They are perfectly suited for the aeration of liquids, such as waste water treatment, printing and paper converting.

Thanks to self-lubricating rotor vanes, no operating fluid is necessary, ensuring a completely dry compression.

Their compact dimensions allow installation to be carried out almost anywhere with ease.

All SECO SD products

SECO SV

- Dry-running rotary vane vacuum technology

- Reliable oil-free vacuum generation

- Robust construction

- Lifetime-lubricated bearings

- Compact dimensions

- State-of-the-art precision manufacturing

Benefits of the SECO SV series

SECO SV dry-running rotary vane vacuum pumps are the ideal choice for any application where reliable, oil-free vacuum is required. They are perfectly suited for use in pick and place applications for clamping and holding, the medical, electronic, packaging and printing industry.

Thanks to self-lubricating rotor vanes, no operating fluid is necessary, ensuring a completely dry operation.

Their compact dimensions allow installation to be carried out almost anywhere with ease.