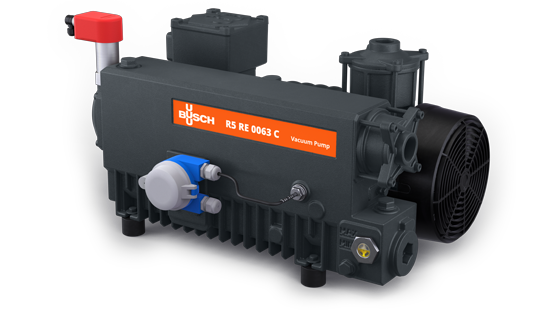

R5 RE 0040/0063 C

Oil-lubricated rotary vane vacuum pumps

Or call us directly: +1-800-USA-PUMP (872-7867)

The Robust and Explosion-Proofed Solution

Explosion-proof

ATEX-certified to directive 2014/34/EU: II 1/2G Ex h IIB3 T4 Ga/Gb, specially designed to extract explosion endangered gas/air and vapor/air mixtures, suitable for the extraction of almost all substances in the IIB3 explosion group as well as petrol vapor

Reliable

Robust construction, highly durable fiber-reinforced epoxy resin vanes, proven rotary vane technology, long service life

Flexible

Various design options available, easy adaption to individual customer requirements and processes, resistance thermometer with transmitter as standard

Technical specifications

Markets & applications

-

Drying

-

Shredding

-

Distillation

-

Upgrading - membrane

-

Upgrading - pressure swing adsorption

-

Filtration

-

Evaporation

-

Distillation

-

Freeze drying

-

Drying

-

Solvent recovery

-

Pneumatic conveying

-

Vacuum for transportation

-

Vacuum packaging

-

Extraction of slaughter waste

-

Sorting of fish eggs

-

Pneumatic suction conveying of ice for cooling

-

Thermoforming

-

Carton packaging

-

Retaining vacuum for filleting

-

MAP packaging

-

Handling / Palletizing

-

Powder processing

-

Oil purification

-

Solvent extraction

-

Water priming

-

Vacuum sewerage

-

Vacuum disposal

-

Ground water removal

Accessories

- Gas-ballast valve

- Oil level switch

- Anti-corrosion coating on the oil separator

- T4 motor and transmitter (temperature class T4 outside the vacuum pump)