Separating out sand and other mineral materials protects downstream purification processes from damage caused by abrasion, blockages and, ultimately, from deposits.

Fig. 1: The sand trap in the Poppenweiler wastewater treatment facility has been in operation since 1976. Source: Busch Vacuum Solutions.

Improving Separation Efficiency of Sand Traps with Claw Compressors

Wastewater treatment facility Poppenweiler

As the first treatment step in wastewater treatment facilities, aerated sand traps are an important process step for optimum and economical wastewater treatment.

Separating out sand and other mineral materials protects downstream purification processes from damage caused by abrasion, blockages and, ultimately, from deposits. In the sand trap of the wastewater treatment facility in Poppenweiler, a district of Ludwigsburg, Germany, the separation efficiency of sand as well as grease and oils has now been optimized using a frequency-controlled MINK claw compressor from Busch Vacuum Solutions. This was possible without the need to make modifications to the geometry of the sand trap.

Wastewater treatment facility Poppenweiler

The Poppenweiler wastewater treatment facility has a population equivalent (PE) of 31,000 and is part of the in-house operation activities of the Ludwigsburg municipal drainage service, which also includes sewage treatment plants in the districts of Eglosheim (18,500 PE) and Hoheneck (167,000 PE). The wastewater treatment facility was commissioned in 1976 and was radically expanded and modernized from 1994 to 1996. The reasons for this were that the old wastewater treatment facility was no longer able to meet the purification performance requirements, primarily with regard to the breakdown of nitrogen and phosphorus. In addition, the communities of Affalterbach and Marbach-Siegelhausen were also connected to the Poppenweiler wastewater treatment facility. Today, the 31,000 PE, size class 4 wastewater treatment facility covers a settlement area of 342 hectares.

The 15-metre long sand trap (Fig. 1) from 1976 is still in use today. It was not expanded during the expansion and modernization measures in the 1990s and had thus reached the limits of its output. This became noticeable due to sand deposits in the primary clarifier and in the downstream aeration tanks. This is why Walter Eichinger, the Operations Manager of all three of the wastewater treatment facilities for the Ludwigsburg municipal drainage service, began looking for a solution for optimizing the separation output of the sand trap as economically as possible.

Based on the German Association for Water, Wastewater and Waste (DWA) guidelines, Helmut Riegraf, Project Manager for the Ludwigsburg municipal drainage service, calculated the necessary dimensions for a sand trap that would enable optimum separation of sand and suspended matter like oils and grease from the organic suspended matter. The result was that the sand trap would need to be at least three metres longer to reduce the flow velocity and thus achieve optimum separation. Because substantial construction costs and downtime would have been associated with extending the sand trap tank, Walter Eichinger and Helmut Riegraf thought about the option of optimizing the circulation of the wastewater with aeration.

They wanted to change the turbulent kinetic energy caused by the rolling speed in the wastewater by changing the air volume flow. So they wanted to use the flow velocity to influence the vertical circulation of the wastewater caused by aeration and its forward motion.

Busch overpressure solution and its benefits for the customer

The already installed rotary lobe blower was not adjustable and thus provided a constant volume flow at an overpressure of 0.5 bar. At that point, Walter Eichinger contacted the Busch Vacuum Solutions. The company recommended installing a MINK claw compressor (Fig. 2) with an external variable speed drive. This compressor also provides constant overpressure of 0.5 bar, but the volume flow can be adjusted with a frequency converter so that it can be precisely adjusted for the requirements in the existing sand trap. Using the operating principle of the claw compressor, it can be adjusted within a large range from 20 to 60 Hertz without affecting the generated overpressure.

They wanted to change the turbulent kinetic energy caused by the rolling speed in the wastewater by changing the air volume flow. So they wanted to use the flow velocity to influence the vertical circulation of the wastewater caused by aeration and its forward motion.

Busch overpressure solution and its benefits for the customer

The already installed rotary lobe blower was not adjustable and thus provided a constant volume flow at an overpressure of 0.5 bar. At that point, Walter Eichinger contacted the Busch Vacuum Solutions. The company recommended installing a MINK claw compressor (Fig. 2) with an external variable speed drive. This compressor also provides constant overpressure of 0.5 bar, but the volume flow can be adjusted with a frequency converter so that it can be precisely adjusted for the requirements in the existing sand trap. Using the operating principle of the claw compressor, it can be adjusted within a large range from 20 to 60 Hertz without affecting the generated overpressure.

-

Fig. 2: MINK claw compressor for aerating the sand trap. Source: Busch Vacuum Solutions.

With the new MINK claw compressor from Busch, Walter Eichinger performed tests over several weeks to achieve the optimum separation efficiency in the sand trap. He ultimately concluded that the best results were achieved by operating the compressor at 35 Hertz and that this is largely independent of the wastewater pollution or the flow velocity. When the wastewater volume is high, the intervals for suctioning off the sand must simply be increased. The MINK claw compressor is installed in the acoustic enclosure of the old rotary lobe blower even though it is significantly quieter. The frequency converter is mounted on the wall and easily accessible so the speed can be changed easily with the push of a button if needed.

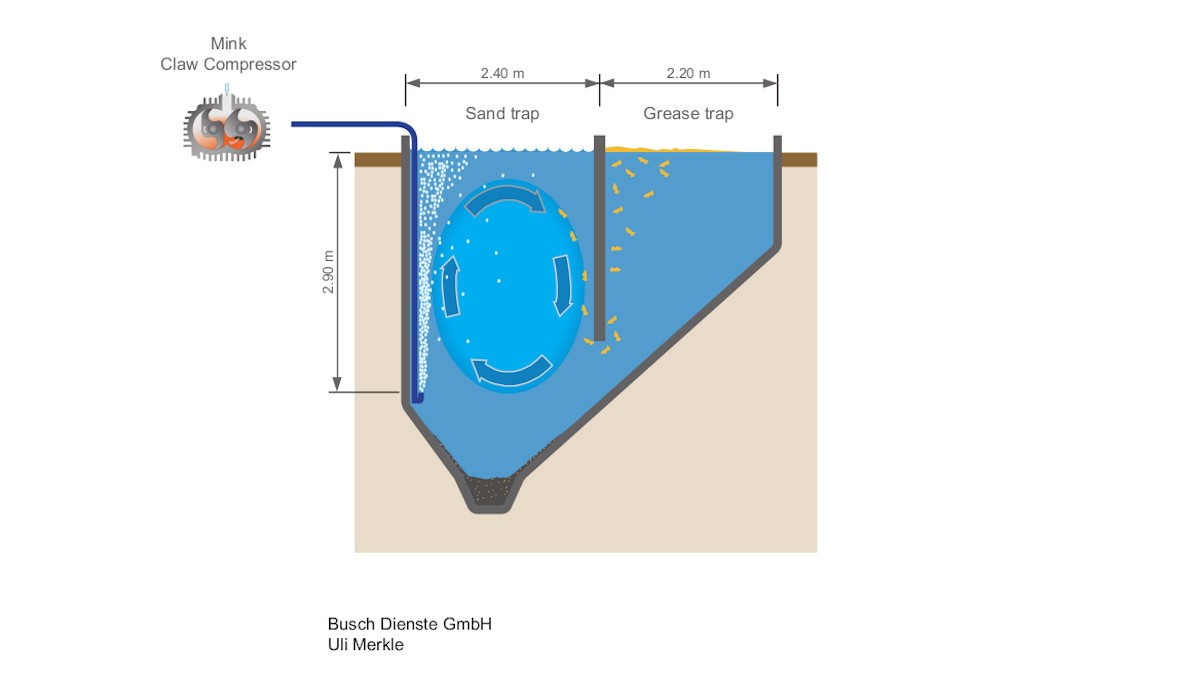

Now this solution introduces the exact amount of air needed with several nozzles, which are attached along the entire length of the sand trap (Fig. 3) at a depth of 2.90 metres. The rolling movement that they cause in the wastewater is now regulated by its circulation velocity in such a way that sand and other mineral materials settle in the tank’s sand trap channel. At the same time, the organic materials remain suspended and exit the sand trap to the aeration tanks via the primary clarifier, where they are needed for denitrification. Rolling movement that is too weak due to insufficient aeration may lead to unwanted deposits of organic materials in the form of sludge at the bottom of the tank and in the sand trap channel. Separation of oils, greases and other suspended materials was also improved so they swim at the top of the grease trap and can be skimmed.

Now this solution introduces the exact amount of air needed with several nozzles, which are attached along the entire length of the sand trap (Fig. 3) at a depth of 2.90 metres. The rolling movement that they cause in the wastewater is now regulated by its circulation velocity in such a way that sand and other mineral materials settle in the tank’s sand trap channel. At the same time, the organic materials remain suspended and exit the sand trap to the aeration tanks via the primary clarifier, where they are needed for denitrification. Rolling movement that is too weak due to insufficient aeration may lead to unwanted deposits of organic materials in the form of sludge at the bottom of the tank and in the sand trap channel. Separation of oils, greases and other suspended materials was also improved so they swim at the top of the grease trap and can be skimmed.

-

Fig. 3: Cross-sectional drawing of the sand trap. Source: Busch Vacuum Solutions.

In this way it was possible to increase the capacity of the over 40-year old sand trap at relatively low cost so that as little sand and other mineral material as possible are able to make it into and settle in the downstream mechanical and organic treatment steps. This also improved the functionality and reliability of the entire wastewater treatment facility.

And Walter Eichinger also noticed a further advantage from the new MINK claw compressor: compared to the previous rotary lobe blower, the claw compressor is more energy-efficient and is equipped with an IE3 energy-saving motor, which translates to energy savings of approximately 33%. Maintenance is limited to an annual oil change, which is performed by a Busch service technician.

And Walter Eichinger also noticed a further advantage from the new MINK claw compressor: compared to the previous rotary lobe blower, the claw compressor is more energy-efficient and is equipped with an IE3 energy-saving motor, which translates to energy savings of approximately 33%. Maintenance is limited to an annual oil change, which is performed by a Busch service technician.