How to save energy for a greener future

Climate change is one of the biggest concerns of our time.Energy production and consumption are two of the largest polluters, responsible for over half of all harmful greenhouse gas emissions.

Energy demand is steadily growing as our population and industrialization continue to expand. Therefore, energy saving is now more important than ever.

Together, we contribute towards a better future for our planet.

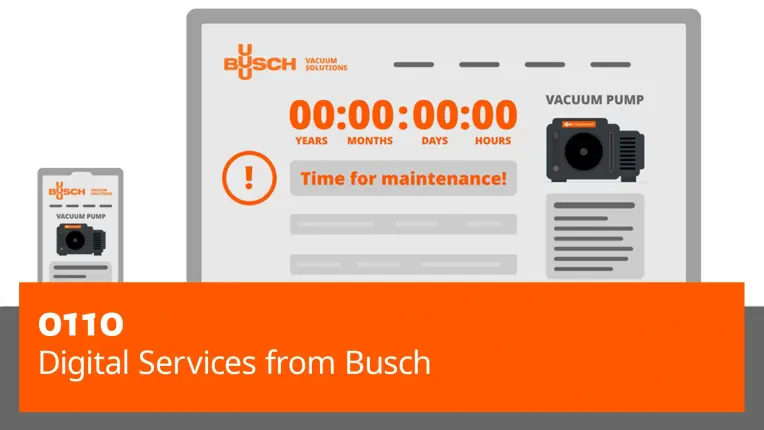

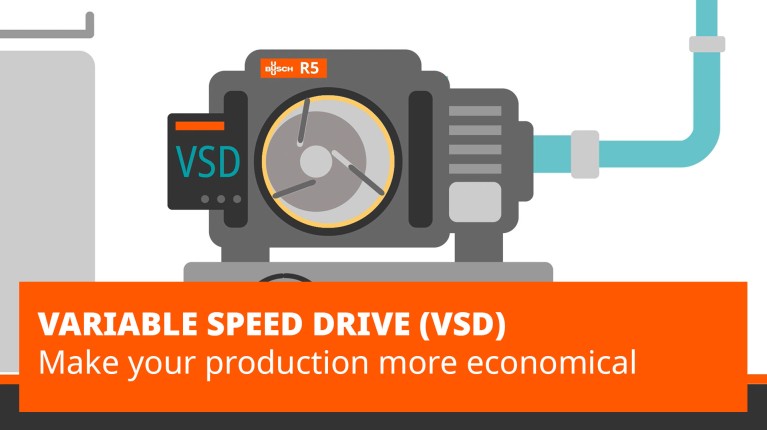

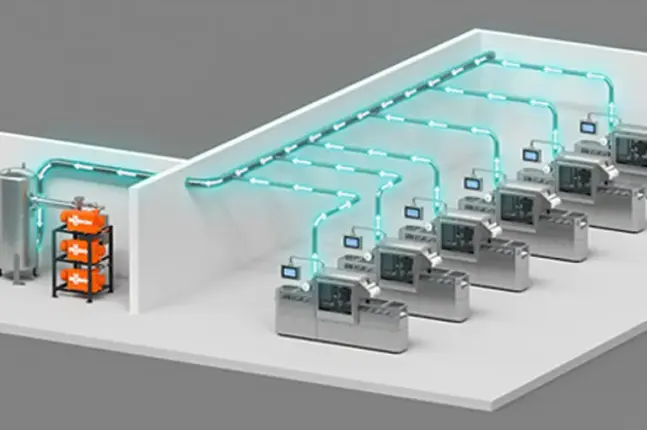

Find out which solution fits your needs best: