- Extremely high vapor and particle tolerance

- For harsh process conditions

- Various sizes and versions

- Different operating fluids possible

DOLPHIN

Liquid ring vacuum pumps and compressors

DOLPHIN are the robust liquid ring vacuum pumps and compressors from Busch. This series encompasses decades of experience in the use and further development of liquid ring technology.

Their proven operating principle provides virtually isothermal (cold) compression which is especially useful for sensitive or hazardous gases.

They are the perfect solution for demanding applications. For example, the evacuation of saturated gases and vapors.

The DOLPHIN series comprises a large variety of sizes and assemblies: single- or two-stage, with a directly flange-mounted motor, or assembled on a base plate, vacuum pumps and compressors.

Operating principle

DOLPHIN are single- or two-stage liquid ring vacuum pumps and compressors.An eccentrically mounted impeller rotates in a housing partially filled with operating fluid. The impeller blades dip into the fluid, and the centrifugal force exerted by their rotation forms a so-called liquid ring within the housing.

The pumped medium is transported in the spaces between the blades and the liquid ring. The eccentric rotation of the impeller alters the volume of these spaces. Thereby, the gas is drawn in, compressed and expelled.

In the single-stage versions, compression is carried out once. In the two-stage versions, the pumped medium is compressed again to allow higher vacuum levels to be achieved. Operation as a compressor is possible.

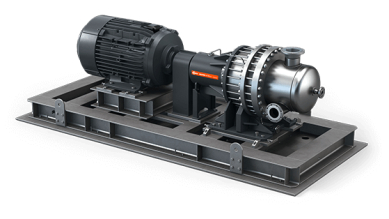

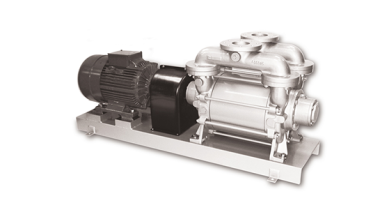

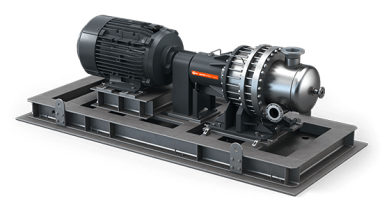

DOLPHIN LA/LB

Benefits of the DOLPHIN LA/LB series

DOLPHIN LA/LB is our series of robust and reliable liquid ring vacuum pumps in base plate design. Their proven operating principle allows them to be used in many sectors of industry.

Even demanding applications, such as evacuating saturated gases and vapors are possible without problems. Different operating fluids may be used according to process conditions.

Thanks to the modular design, various assemblies are possible. The precisely dimensioned range of sizes, a wide variety of shaft sealing options, choice of accessories and construction materials allows you to find the perfect DOLPHIN LA/LB for your process.

DOLPHIN LA are single-stage vacuum pumps whereas DOLPHIN LB have two stages for a higher vacuum.

All DOLPHIN LA/LB products

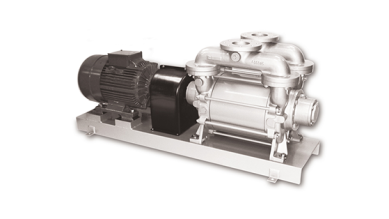

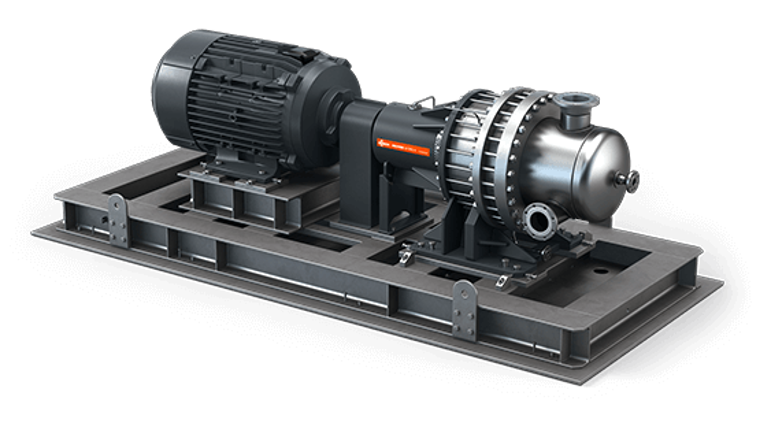

DOLPHIN LG/LR

- Extremely high vapor and particle tolerance

- For harsh process conditions

- Various sizes and versions

- Different operating fluids possible

Benefits of the DOLPHIN LG/LR series

DOLPHIN LG/LR is a series of high-capacity liquid ring vacuum pumps. They can be used in many industrial sectors, even for demanding applications. For example, the discharge of particle-laden gases or highly saturated vapors.

Their modular base plate design allows these vacuum pumps to be perfectly adapted to many different industrial processes.

Various assemblies and construction materials are possible, including cast iron (EN-GJL-200) and 316 grade stainless steel.

A wide variety of operating fluids can be used to perfectly match all process requirements.

All DOLPHIN LG/LR products

DOLPHIN LM/LT

- Extremely high vapor and particle tolerance

- For harsh process conditions

- Universal flanges

- Various sizes and versions

- Easy servicing

Video: How DOLPHIN LM/LT vacuum pumps work

Benefits of the DOLPHIN LM/LT series

The DOLPHIN LM/LT series is the latest generation of liquid ring vacuum pumps from Busch. It combines all the advantages of proven technology with additional refinements.

Even demanding applications such as evacuating saturated gases and vapors are possible without problems. Their operating fluid is usually water, but other liquids may be used if required by the process conditions.

Their new sealing concept with optimized Viton or FFKM seals makes them suitable for most applications.

Universal flanges allow for simple fitting or replacement of existing vacuum pumps. The precisely dimensioned range of sizes and the choice of accessories and construction materials allows you to find the perfect DOLPHIN LM/LT for your process.

DOLPHIN LM are single-stage vacuum pumps whereas DOLPHIN LT have two stages for a higher vacuum. More than ten sizes allow an exact match to every process.

All DOLPHIN LM/LT products

DOLPHIN LN

- API-681 standard

- ATEX-certified

- Minimum thermal expansion

- Modular design

- Easy cleaning with hot steam

- Test run without operating fluids possible

- Easy start function

Benefits of the DOLPHIN LN series

DOLPHIN LN liquid ring compressors have been specially designed for all demanding overpressure applications in the oil and gas industry. They are perfectly suited for flare gas recovery and off-gas or chlorine gas compression.

Of course, they comply with the API-681 standard and are ATEX-certified.

Their oval-shaped housing, together with operating liquid management via cylindrical type distributor, ensures reliable operation. Being not sensitive to thermal expansion, there is no risk of rotor seizing. Even an unlikely axial shift of the impeller is tolerated.

The modular two-stage design allows for quick replacement of bearings and mechanical seals. No clearance readjustment is necessary at reassembly.

DOLPHIN LN can be cleaned very easily. You just use hot steam while the impeller rotates in the empty compression chamber.

With the innovative easy start function, you can simply turn on the compressor under full discharge pressure. It then builds up performance within ten seconds. There is no need for special shut-down or starting procedure.

All DOLPHIN LN products

DOLPHIN LX

- Compact monobloc design

- Extremely high vapor and particle tolerance

- For harsh process conditions

- Various sizes and versions

Benefits of the DOLPHIN LX series

DOLPHIN LX are robust and reliable liquid ring vacuum pumps in a monobloc design. The directly flange-mounted motor makes them exceptionally compact. Therefore, DOLPHIN LX are very well- suited for integration into existing systems or machines.

Thanks to the robust liquid ring principle, even the extraction of particle-laden gases or highly saturated vapors can easily be carried out.

DOLPHIN LX are available in different construction materials and ATEX versions.

Different operating fluids may be used according to process conditions.

All DOLPHIN LX products

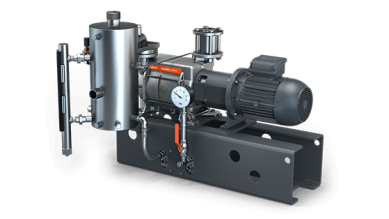

DOLPHIN VX

- Unit installed on stainless steel base frame with integrated separator

- Wide range of processes

- System control complete with instrumentation

- Partial or total recirculation system

Benefits of the DOLPHIN VX series

DOLPHIN VX is the new generation of liquid ring vacuum pump units. They are based on our proven DOLPHIN LX technology. The unit is installed on a corrosion resistant stainless steel base frame with integrated stainless steel operating fluid separator and complete instrumentation.

The VX series has been designed to support a wide range of processes in many different sectors - such as plastics, food and beverage, and general industries.

DOLPHIN VX units are available with a single stage, valved, compact LX vacuum pump with directly flanged motor. Five sizes allow an exact match to every process.

If required by the process conditions, operating fluids other than water may be used. DOLPHIN VX are available as a partial or total recirculation system.

All DOLPHIN VX products

DOLPHIN VL

- Unit installed on base frame

- Operating fluid separator

- System control

- Wide range of sizes

- Continuous flow, partial or total recirculation system

Benefits of the DOLPHIN VL series

DOLPHIN VL is the new generation of liquid ring vacuum pump units. They are based on our proven DOLPHIN LM/LT technology. The unit is installed on a base frame with operating fluid separator and complete instrumentation.

The VL series has been designed to support a wide range of processes in many industrial sectors. Such as plastics, food and beverage, chemical and pharmaceutical industries.

DOLPHIN VL units are available with either single- (DOLPHIN LM) or two-stage (DOLPHIN LT) vacuum pumps. More than ten sizes allow an exact match to every process.

If required by the process conditions, other operating fluids than water may be used. DOLPHIN VL are available as a simple continuous flow system, or as a partial or total recirculation system.