- Advanced screw design

- Dry and contact-free operating principle

- High vapor and particle tolerance, self-draining

- Efficient water cooling

- Optional air cooling

- Anti-corrosion coating

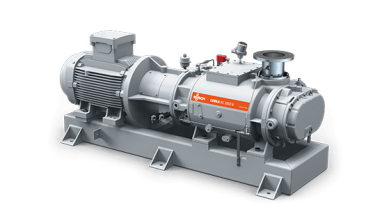

COBRA Industry

Dry screw vacuum pumps

COBRA Industry dry screw vacuum pumps are ideally suited for industrial applications which require reliable and contaminant-free extraction of gases and vapors.

The operating principle of COBRA Industry is based on our state-of-the-art screw technology. With their patented self-balancing screws, they set new standards in terms of efficiency.

COBRA vacuum pumps operate efficiently throughout their vacuum range and deliver constantly high pumping speeds.

COBRA Industry vacuum pumps are oil- and contact-free.

Particle-laden media can be evacuated without any problems. Furthermore, maintenance is reduced to a minimum.

Optimum corrosion resistance is ensured by an even temperature distribution preventing condensation.

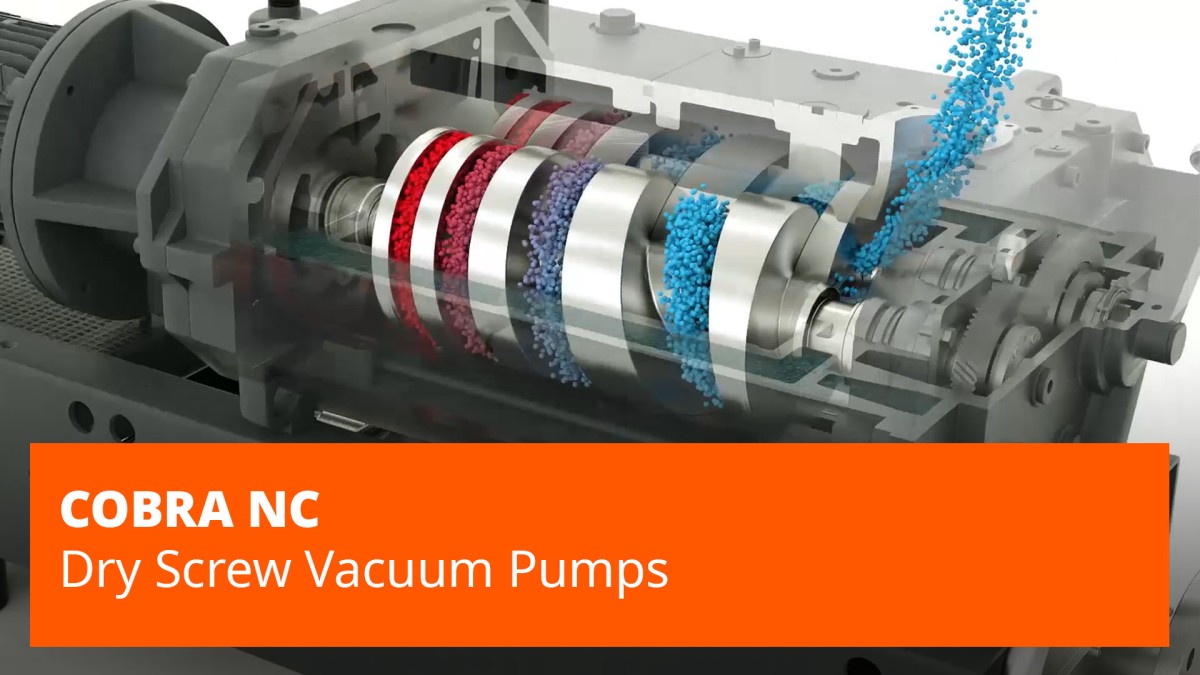

Operating principle

Inside COBRA Industry dry screw vacuum pumps, two screw rotors rotate in opposite directions. The pumped medium is trapped between the cylinder and the screw chambers. There, it is compressed, and transported to the outlet. During this process, the screw rotors do not come in contact with each other or the cylinder.COBRA NX

Benefits of the COBRA NX series

COBRA NX are high-performance dry screw vacuum pumps for rough and medium vacuum applications. They are in use wherever gases and vapors need to be pumped reliably.

The patented self balancing screw design ensures lowest vibration levels and quiet operation.

The screws of COBRA NX vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA NX series vacuum pumps use efficient water cooling. An even temperature distribution throughout the pump body is therefore maintained. Moreover, thermal stability during the process is ensured.

All COBRA NX products

All COBRA NX ECOTORQUE products

COBRA NC

- Advanced screw design

- Dry and contact-free operating principle

- High vapor and particle tolerance, self-draining

- Efficient indirect water cooling

- Air cooling and various sealing and coating configurations available

- ATEX-certified versions available

Video: How COBRA NC vacuum pumps work

Benefits of the COBRA NC series

COBRA NC are high-performance dry screw vacuum pumps. They are perfectly suited for demanding applications with maximum flexibility and modularity for process changes. COBRA NC are in use wherever gases and vapors need to be pumped reliably.

The patented self balancing screw design ensures lowest vibration levels and quiet operation.

The screws of COBRA NC vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA NC series vacuum pumps use efficient indirect water cooling. This results in an even temperature distribution throughout the pump body. Moreover, thermal stability is ensured throughout the process.

The COBRA NC series comprises a range of application-specific versions. ATEX-certified versions for use in explosion-hazard environments are also available.

All COBRA NC products

All COBRA NC ECOTORQUE products

COBRA DX PLUS

- Plug&Pump concept

- Touch screen with intuitive menu navigation

- Integrated variable speed drive

- Reduced footprint

- Effective indirect water cooling

- Advanced screw design

Video: How COBRA DX PLUS vacuum pumps work

Benefits of the COBRA DX PLUS series

COBRA DX PLUS are high-performance dry screw vacuum pumps for many industrial rough and medium vacuum applications, e.g. solar panel and lithium battery production, drying, food packaging or vacuum furnaces.

Thanks to the Plug&Pump concept, DX series vacuum pumps are very user-friendly. No further installation is needed before start-up.

They feature a touch screen with intuitive menu navigation, allowing control of major functionalities. An integrated variable speed drive with different operating modes saves energy by ensuring that COBRA DX PLUS series vacuum pumps always run in optimum operating conditions.

The patented self-balancing screw design ensures the lowest vibration levels and quiet operation. The screws of COBRA DX PLUS vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA DX PLUS series vacuum pumps use efficient water cooling, ensuring even temperature distribution throughout the pump body and thermal stability during your process.

All COBRA DX PLUS products

COBRA DH

- Plug&Pump concept

- Touch screen with intuitive menu navigation

- Automatic standby mode

- Hermetic sealing

- Advanced screw design

- Optional energy-saving module VacBoost

Benefits of the COBRA DH

COBRA DH dry screw vacuum pumps are the compact and intelligent plug&pump solution with an integrated vacuum booster.

They have been specially designed for a wide range of industrial vacuum applications, including glass coating, battery drying, vacuum furnaces, laminating, and flat panel display production.

The plug&pump concept ensures that the DH series vacuum pumps are extremely user-friendly, requiring no additional installation before start-up.

They feature a 7" color touch display with intuitive menu navigation, allowing for the control and monitoring of major functionalities as well as operating parameters.

Equipped with the optional energy-saving module VacBoost, the COBRA DH ensures low energy consumption and high process efficiency. Additionally, an automatic standby mode provides significant cost savings during operation while maintaining the required vacuum level.

Thanks to hermetic sealing, the vacuum pumps offer extended maintenance intervals and high uptime, ultimately reducing long-term operating costs.

All COBRA DH products

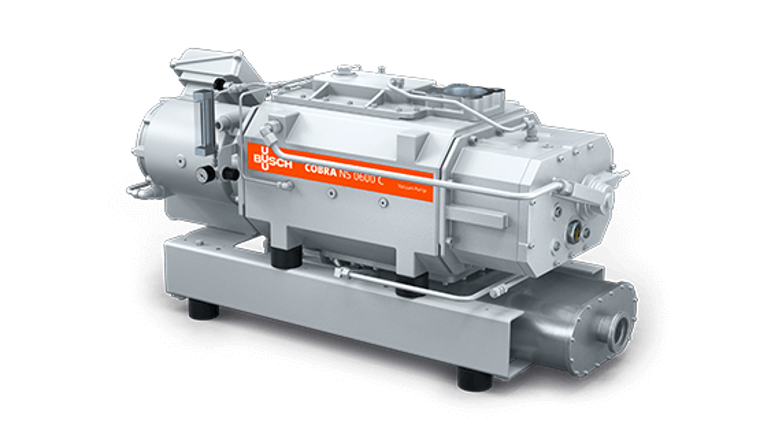

COBRA NS

- Advanced screw design

- Dry and contact-free operating principle

- High vapor and particle tolerance, self-draining

- Leak-tightness

- Extended service intervals

- Efficient indirect water cooling

- Quiet

Benefits of the COBRA NS series

COBRA NS is a series of high-performance dry screw vacuum pumps for demanding applications. They are in use wherever gases and vapors need to be pumped reliably, such as coating applications, helium pumping or fluorination.

The integrated motor makes this vacuum pump series leak-tight with a leakage rate of < 5.0 · 10-5 mbar · l/s.

The bearings of COBRA NS vacuum pumps are lubricated with Busch PFPE oil. Therefore, service intervals are extended to a maximum.

The screws of COBRA NS vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented. Optimum corrosion resistance is furthermore ensured thanks to temperature control and special coatings on the screws.

COBRA NS series vacuum pumps use efficient indirect water cooling. An even temperature distribution throughout the pump body is therefore maintained. Moreover, thermal stability during the process is ensured.

All COBRA NS products

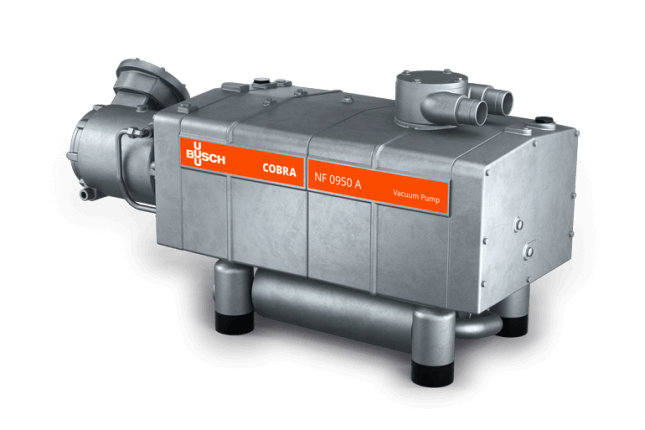

COBRA NF

- Advanced screw design

- Dry and contact-free operating principle

- Optimized for vacuum packaging

- Easy cleaning with steam jets and conventional detergents

- Efficient water cooling

- Quiet

- Compact design

Benefits of the series

COBRA NF dry screw vacuum pumps have been specially designed for vacuum packaging. They offer fast pump-down of the packaging chamber and maximum productivity.

The patented self balancing screw design ensures lowest vibration levels and quiet operation.

The screws of COBRA NF vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

You can easily clean COBRA NF series vacuum pumps using steam jets and conventional detergents. Because of the smooth surface design water and detergents drain away leaving a residue-free finish.

Thanks to an efficient water cooling, only ten percent of the generated heat are released into the environment.

The COBRA NC 0500 B also belongs to this series, which has been specially designed for food applications.

All COBRA NF products

COBRA DS

- Advanced screw design

- Dry and contact-free operating principle

- Excellent powder handling

- Effective indirect water cooling

- Compact fit-in-place design

- High pumping speed for the discharge of hydrogen

- High-efficiency motor

- Sizes with integrated vacuum booster available

Benefits of the COBRA DS series

COBRA DS dry screw vacuum pumps are the ideal vacuum generators for demanding processes. Even under conditions in which a high hydrogen throughput is required. They are therefore perfectly suited for chemical vapor deposition, rapid thermal processing or atomic layer deposition.

Various sizes of the COBRA DS series feature an integrated high-performance vacuum booster. This combination of backing pump and vacuum booster allows to achieve increased pumping speeds and ultimate pressures.

The patented self-balancing screw design ensures excellent powder handling and high uptime.

The screws of COBRA DS vacuum pumps are manufactured from a single-piece casting avoiding any gaps. This makes an ingress of process fluids or particles impossible. Thus, corrosion and deposition are prevented.

COBRA DS series vacuum pumps use effective, indirect water cooling. As a result, the temperature distribution throughout the pump body can be controlled. A response to process variations is possible at any time.

Due to their fit-in-place design, COBRA DS can be easily and quickly retrofitted to existing systems.

All COBRA DS products

COBRA BA

- Advanced screw design

- Dry and contact-free operating principle

- Unique “flying bearing” design

- Cantilever construction

- Compact design

- Effective air cooling

- Optional frequency converter

Benefits of the COBRA BA series

COBRA BA are proven dry screw vacuum pumps perfectly suited for demanding processes such as sterilization, metallurgy, gas recovery or furnace applications.

The patented self-balancing screw design ensures lowest vibration levels and quiet operation.

COBRA BA vacuum pumps feature a bell-shaped cantilever construction: The twin rotor with variable pitch screws is mounted only on the motor side. Thanks to the unique “flying bearing” design, inlet bearings are unnecessary. Therefore, the pumped medium does not come in contact with the bearings. This ensures clean vacuum generation and allows to fully recover the pumped medium.

COBRA BA vacuum pumps are characterized by an efficient air cooling.

A directly mounted, canned motor makes the dimensions of the COBRA BA series very compact.