Struggling to meet your production goals? Facing high energy consumption or unplanned downtime with your current vacuum supply?

Busch Vacuum Solutions has you covered!At Busch, we do not just sell products – we deliver solutions. Tailor-made vacuum, designed not only to optimize your operations and uncover potential that might still be hidden in the shadows. But also to cut costs and reduce downtime.

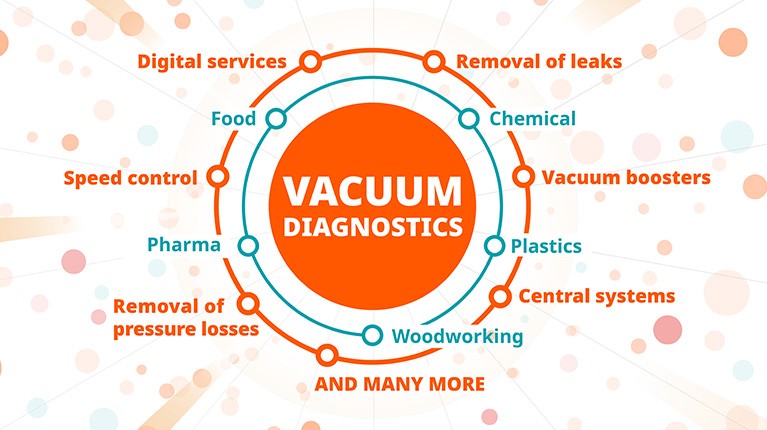

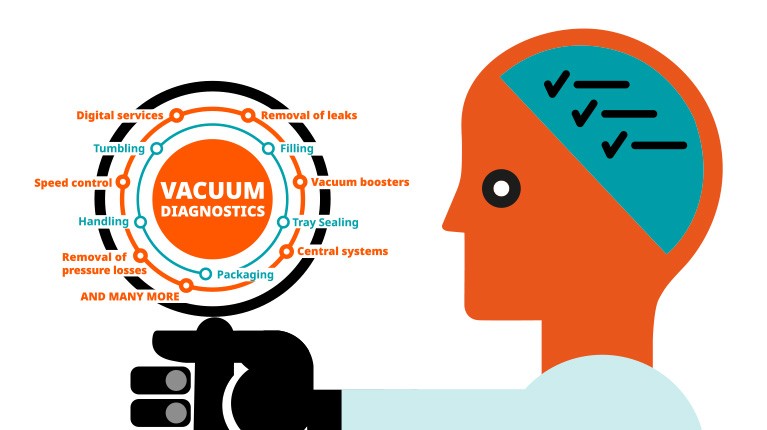

With our unique Vacuum Diagnostics, we examine and analyze your specific requirements, processes, and equipment. Whatever your industry, we have the expertise to optimize your vacuum supply. Ensuring your applications deliver peak performance.

Ready to level up? Discover how our expertise can transform your business today.