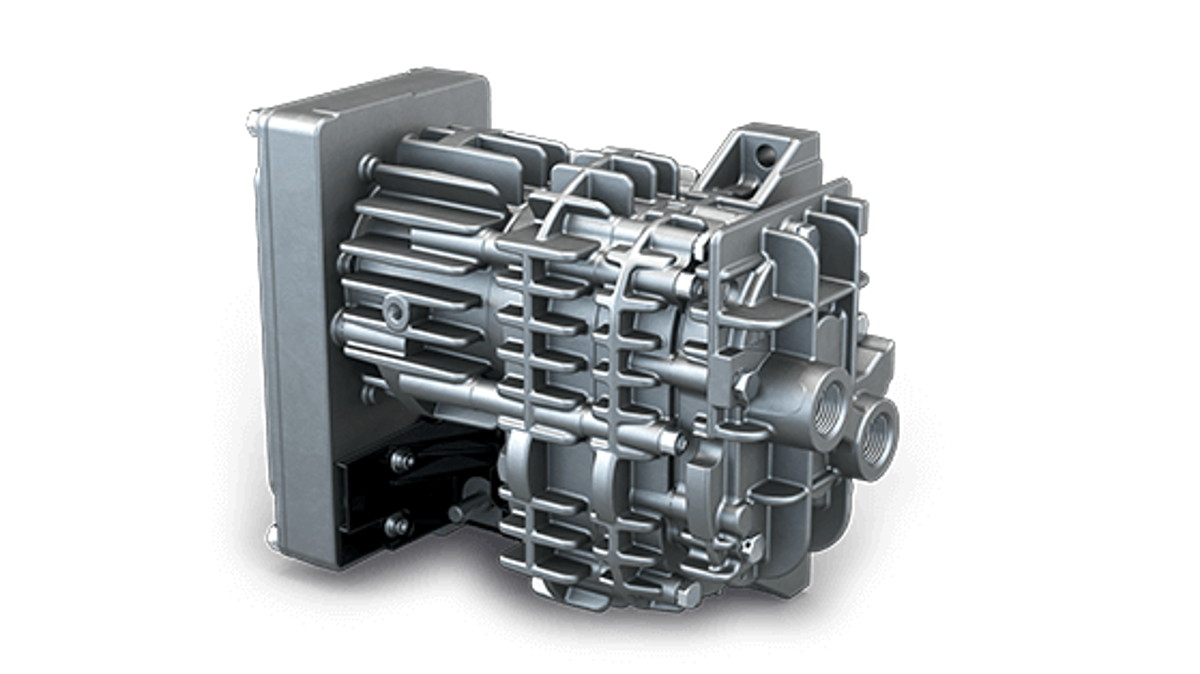

Ar comprimido para aplicações móveis sob condições extremas

Robusto

Especialmente concebido para o transporte de ar em aplicações móveis, pode ser operado em condições extremas, em faixas de temperatura entre -40°C e +100°C e em elevações entre -1000 m e 4000 m, resistente a vibrações severas

Eficiente

Última tecnologia em compressores de rotores de garra, compressão a seco e sem contacto, sem contaminação do meio bombeado, acionamento inteligente de velocidade variável, baixo consumo energético, longo ciclo de vida sem manutenção

Compacto

Pegada reduzida graças ao design "tudo-em-um"

Especificações técnicas

Mercados e aplicações

Manuseamento de biogás

-

Circulação

Tratamento de águas residuais

-

Circulação de água por filtros de areias

-

Circulação de biogás

-

Aeração de tanques de aeração