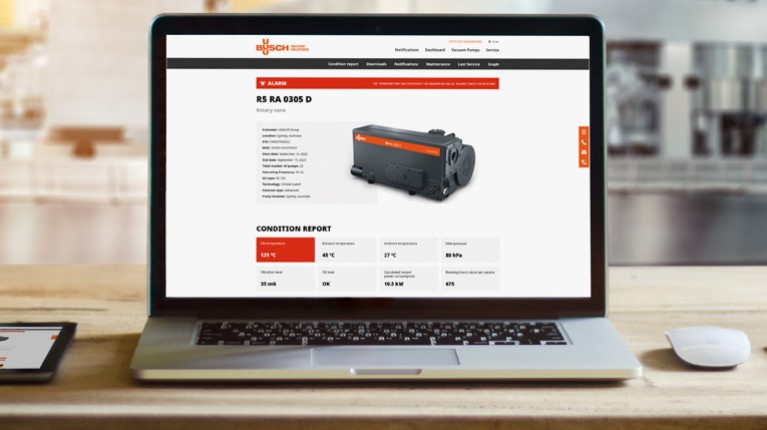

The New Benchmark of Rotary Vane Technology

Efficient

Up to 30% more energy-efficient than comparable rotary vane vacuum pumps, low operating costs, high uptime, reduced heat emission, optimized heat direction

High performance

Specially designed for use in vacuum packaging machines, optimized for fast cycle times, e.g. vacuum packaging and continuous operation at low pressures

Easy servicing

All service-relevant parts on one side, service routine significantly faster, smooth surface design for easy cleaning

Technical specifications

Markets & applications

Automotive and transport

-

Leak Detection and EoL Testing

-

Heat Treatment

-

Vacuum Die Casting

-

Vacuum Sewage

-

E-Beam Welding

-

3D Printing

Chemical industry

-

Packaging

Food packaging

-

Round-table/Carousel packaging machines

-

Thermoforming machines forming station

-

Chamber machines large industrial

-

Blister packaging

-

Cartoning machines

-

Tray sealers

-

Thermoforming packaging machines - Sealing/evacuation station

-

Molding

Food processing

-

Powder processing

Hydrogen

-

Leak Detection and EoL Testing (Master)

Lithium-ion battery production

-

Leak Detection and EoL Testing (Master)

Metallurgy

-

Heat Treatment

-

Die Casting

-

Vacuum Brazing / Soldering

-

Vacuum Sintering

-

3D Printing

-

E-beam welding

Pharmaceutical industry

-

Packaging

Refridgeration

-

Leak Detection and EoL Testing

-

Vacuum Evacuation and Filling

Technical gases

-

Liquefaction

-

Gas Transport

-

Insulation Vacuum

-

Bottle Filling

Thin film coating

-

Decorative Coating

-

Optical Coating

-

Wear Protection Coating

Wastewater treatment

-

Vacuum Sewage

Accessories

- Vertical inlet

- Larger gas-ballast valve

- Various inlet filters

- Adapter flange for vacuum booster

- Filter pressure gauge

- Cooling air deflector

- G 2" exhaust connection flange

- Energy recuperation kit with heat exchanger

- Vacuum pump oils for all applications

- Oil level switch

- Temperature sensors

- Starter unit

Design options

-

ATEX - for use in explosion hazard areas.