PLUS

The intelligent solution for your vacuum process

The PLUS in the name makes the difference. PLUS technology combines proven Busch experience with cutting-edge features for Industry 4.0. Everything you need in one unit.

Learn more about PLUS vacuum pumps

Your benefits at a glance

More than just vacuum pumps. With the PLUS technology you get your PLUS of possibilities:

- Fully connected

- Integration to any standard control system

- Remote control of the vacuum pump possible

- Advanced control functionalities

- Two operating modes: constant speed and pressure control

- Large high-definition color touch screen

- Intuitive menu navigation

- Operating data and the condition of the components are recorded permanently

- Data can be accessed directly on the built-in display or transferred via a Modbus TCP/IP client/server protocol

- Large pumping speed range thanks to a variable speed drive

Operating modes

Users can choose between constant speed mode or pressure control mode, making the vacuum pump exceptionally energy-efficient.

Constant speed mode

For processes with constant vacuum demand, it is recommended to leave the PLUS vacuum pump running at constant speed.Pressure control mode

For processes with changing vacuum demand over time, the pressure control mode is the ideal choice. In this case the PLUS vacuum pump adjusts the rotational speed according to the required vacuum level.Once this vacuum level has been achieved, the PLUS vacuum pump continues to run at minimum speed, enabling it to respond to a sudden need for increased vacuum demand and leading to further energy savings.

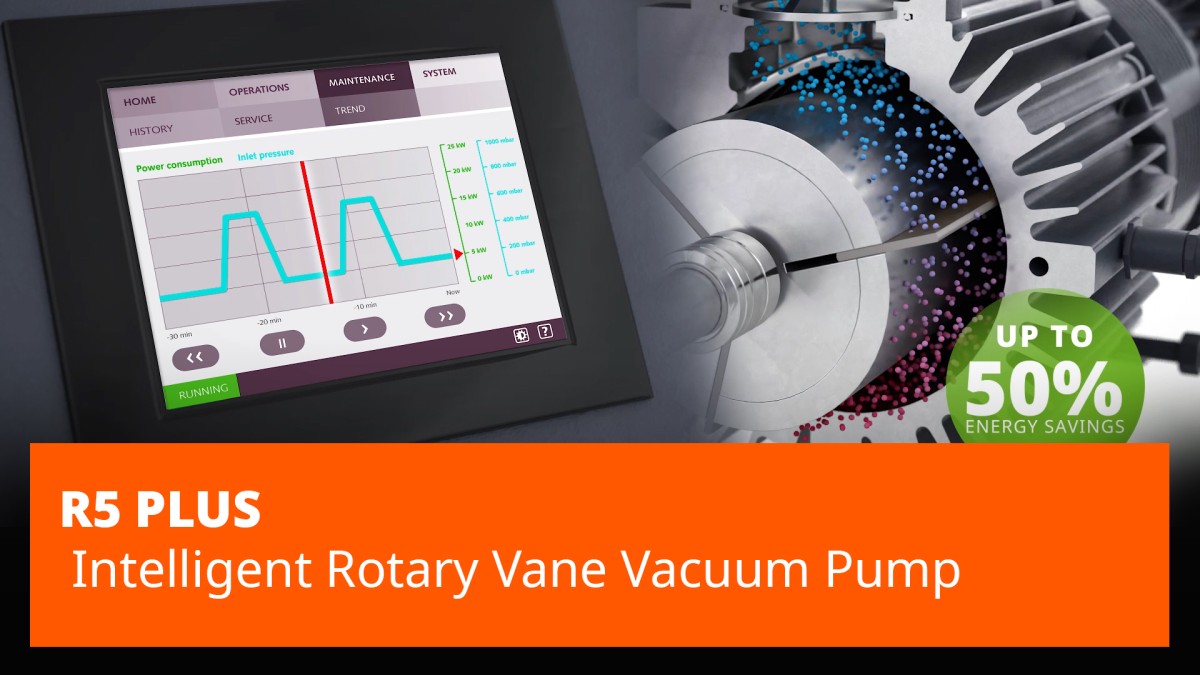

R5 PLUS

Operating principle

R5 rotary vane vacuum pumps

In a cylindrical housing, a rotor with several vanes is mounted eccentrically. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. The pumped medium is trapped inside these chambers. During further rotation, their volume is constantly reduced. Thereby, the pumped medium is compressed and transported to the outlet.

Video: How R5 PLUS vacuum pumps work

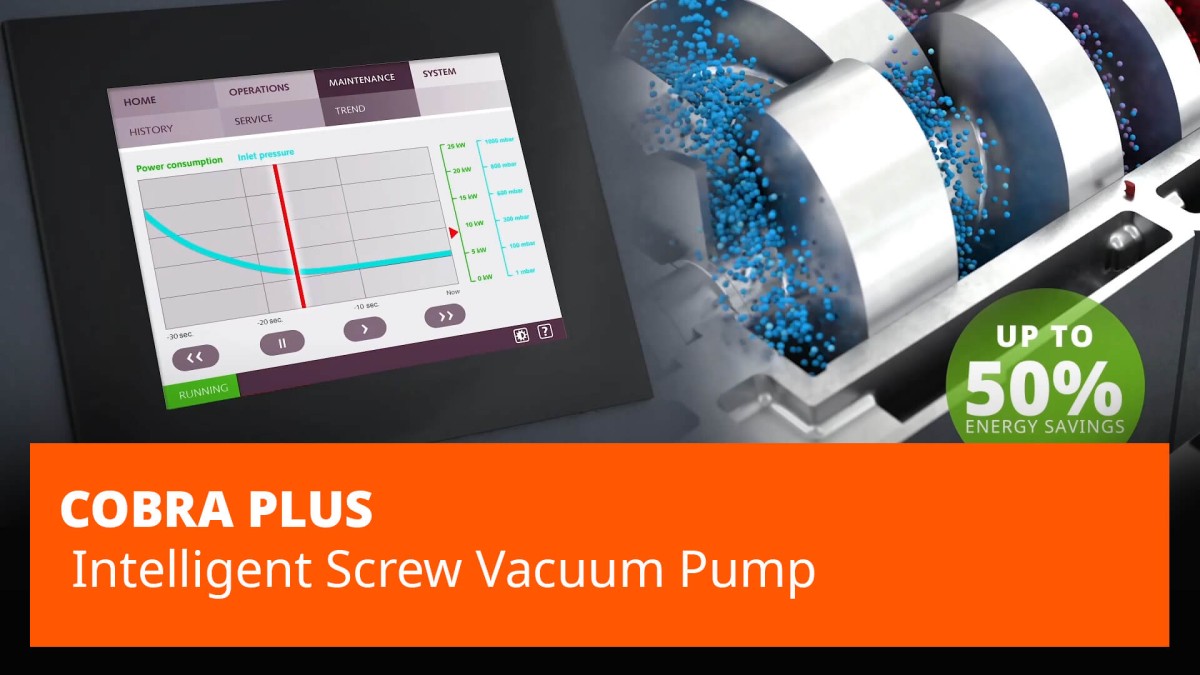

COBRA PLUS

Operating principle

Video: How COBRA PLUS vacuum pumps work

PLUS Master Control

FAQ

What is the difference between R5 PLUS and COBRA PLUS?

R5 PLUS and COBRA PLUS vacuum pumps generate vacuum in two different ways.

R5 PLUS vacuum pumps operate according to the proven rotary vane principle and are oil-lubricated. COBRA PLUS vacuum pumps are based on screw vacuum technology which works completely dry.

How do the PLUS vacuum pumps differ from ordinary vacuum pumps?

PLUS are our fully connected vacuum pumps. They enhance proven Busch technology with control, condition monitoring and communication. This makes the PLUS family ready for Industry 4.0.

Why are the PLUS vacuum pumps ready for Industry 4.0?

The fully connected PLUS series vacuum pumps bring the proven Busch vacuum technology to the next level. With advanced control and monitoring functionalities they are ready for Industry 4.0.

The Modbus TCP/IP protocol allows integration into any standard process control system.

On the large high-definition color touch screen power consumption, oil temperature as well as inlet and outlet pressure curves can be displayed and therefore easily be supervised. In addition, oil level and motor frequency are always in view.

All relevant parameters can be adjusted and monitored allowing a perfect match to every process.

How do the PLUS vacuum pumps improve the efficiency and reduce the operating costs?

An integrated variable speed drive allows adjustments of the motor frequency. This leads to energy savings of up to 50% compared to unregulated vacuum pumps.

Different operating modes ensure that PLUS series vacuum pumps always run in optimum operating condition. In combination with the intelligent pressure control, ECO mode settings and the auto restart function further energy and cost savings are possible.

What is a variable speed drive and what are its benefits?

The variable speed drive allows adjustments of the motor frequency. This leads to significant energy savings compared to unregulated vacuum pumps.

Which process parameters can be controlled and monitored with the PLUS vacuum pumps?

On the large high-definition color touch screen power consumption, oil temperature as well as inlet and outlet pressure curves can be displayed and therefore easily be supervised. In addition, oil level and motor frequency are always in view.

All relevant parameters can be adjusted and monitored allowing a perfect match to every process.

Can the operating time of the PLUS vacuum pumps be determined and scheduled? And how does it work?

PLUS vacuum pumps have an integrated week planner, which allows to schedule the operating time of the PLUS vacuum pump day by day. The week planner can be accessed on the large high-definition color touch screen.

Can maintenance intervals be planned more precisely? And how does it work?

Yes, maintenance intervals can be planned more precisely.

The condition of the components, the event history and the running hours are recorded permanently. The required maintenance interval can thus be adjusted and indicated accordingly. As a result, service intervals can be longer and service costs can be reduced.

When does the vacuum pump give warnings or alarms?

For all relevant parameters warning and alarm thresholds are predefined, so the safety of the process and the vacuum pump is always ensured.

Warnings and alarms can be programmed for example if the oil temperature exceeds a certain level.