Overpressure and Vacuum Applications

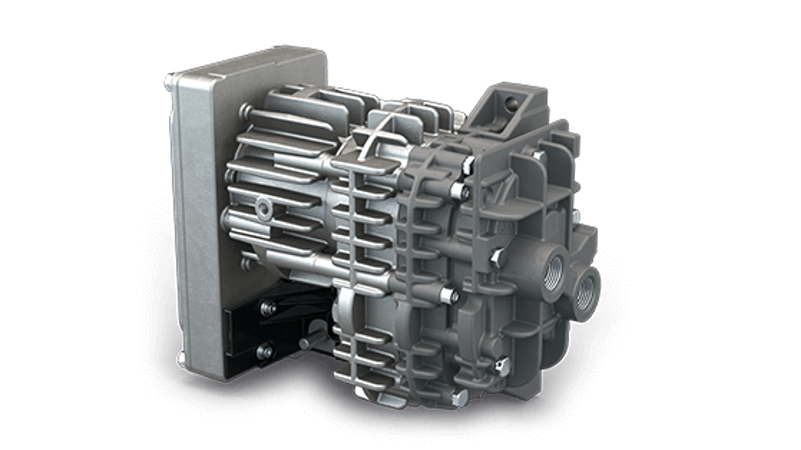

We have the optimum vacuum for your application.

Applications of vacuum technology

Learn more about vacuum applications

What is vacuum needed for?

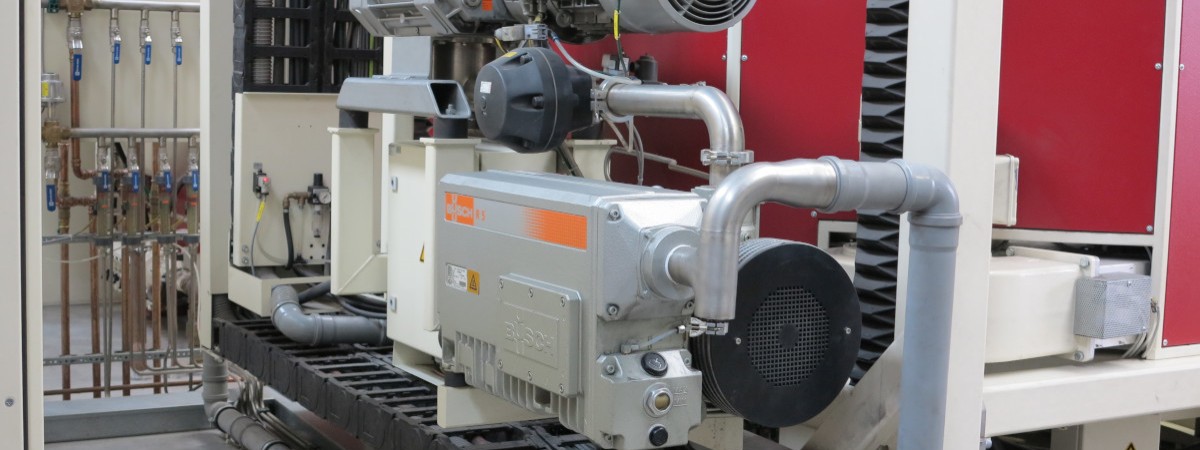

The short answer is, many things. Vacuum pump solutions save energy, money and time. They also improve product quality, extend shelf life, make processes safer, speedier and smoother, cut pollution, and even help save lives.

The range of vacuum technology is quite breath-taking. It plays a role in the production of food, medicines, explosives, wind turbines, district heating, stainless steel, and much more. It also contributes to game-changing high vacuum research in physics and chemistry.

However, the fundamental role of a vacuum system, its science, still remains the same: reduce the number of gas particles in a system which, at constant temperature, corresponds to a reduction in gas pressure.

And this is a process that continues to affect our lives every single day.

What are the most prominent vacuum applications?

While it is impossible to list all areas where vacuum technology is employed, here is a brief overview of common industrial vacuum applications.

In packaging processes, vacuum solutions are used, for example, in vacuum packaging or modified atmosphere packaging (MAP), tray forming in packaging machines, thermoforming of plastic packaging, foil handling in tubular bag packaging machines, carton erection, labeling and many more.

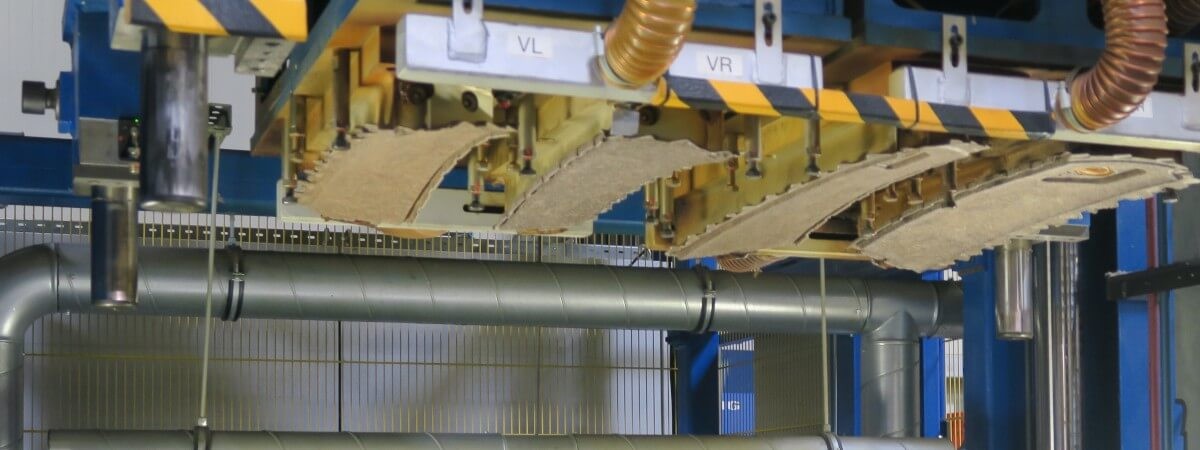

The use of vacuum in forming, pressing and laminating applications enables mold evacuation, thermoforming and vacuum-assisted resin transfer molding (VRTM). Moreover, vacuum is indispensable for the production of flat panel displays and solar panels.

Many “thin-film” technologies have been made possible through advances in vacuum coating processes, such as physical and chemical vapor deposition, metallization and many more.

Vacuum distillation is used in the chemical and pharmaceutical industry, for solvent recovery, as well as in crude oil distillation processes.

Vacuum degassing and deaeration processes play a role in the production of foodstuffs, high-quality alloy and oil, as well as in plastics extrusion.

In pneumatic conveying processes, vacuum and low pressure solutions can, for instance, be found in applications such as the pneumatic conveying of bulk goods like granulates, grains, powders or dusts.