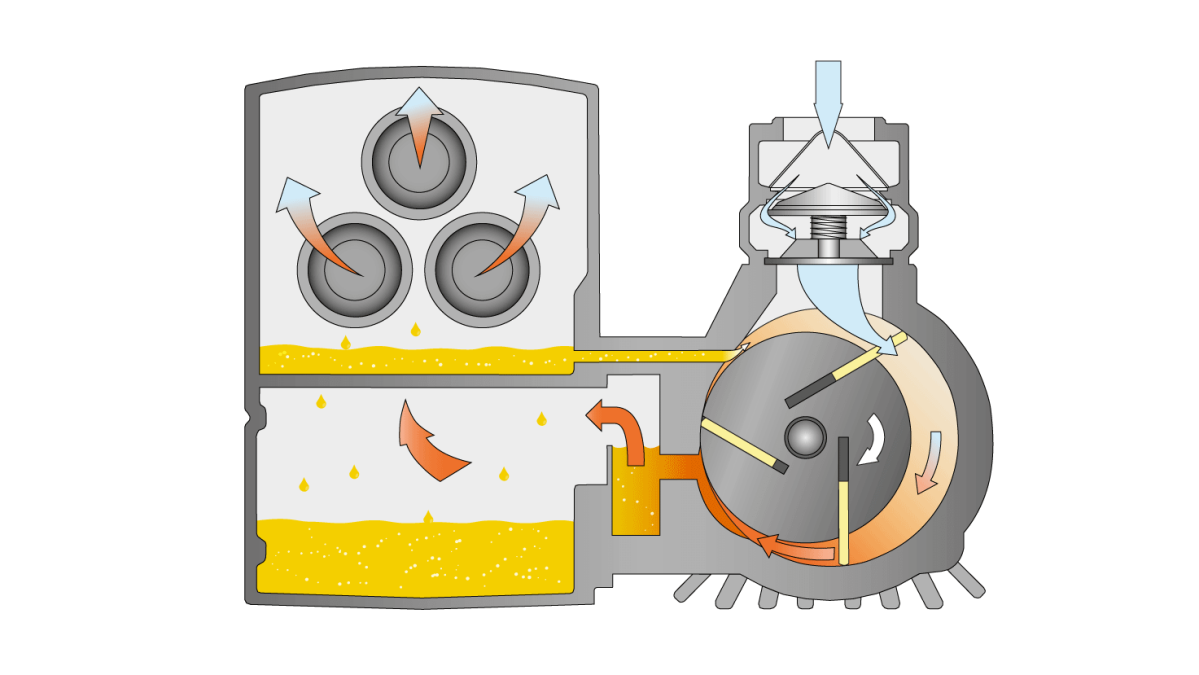

How to change oil filters

Changing your oil filter should not be a challenge. Our video demonstrates how you can easily remove and install our Busch genuine oil filters on an R5 vacuum pump.Do you need help changing your oil filter? Your local Busch service expert is happy to help! You can also make use of our service contracts: Let us take responsibility for your maintenance while you concentrate on your core business.

_news_article_1200x675.jpg)