How does aeration in wastewater treatment work?

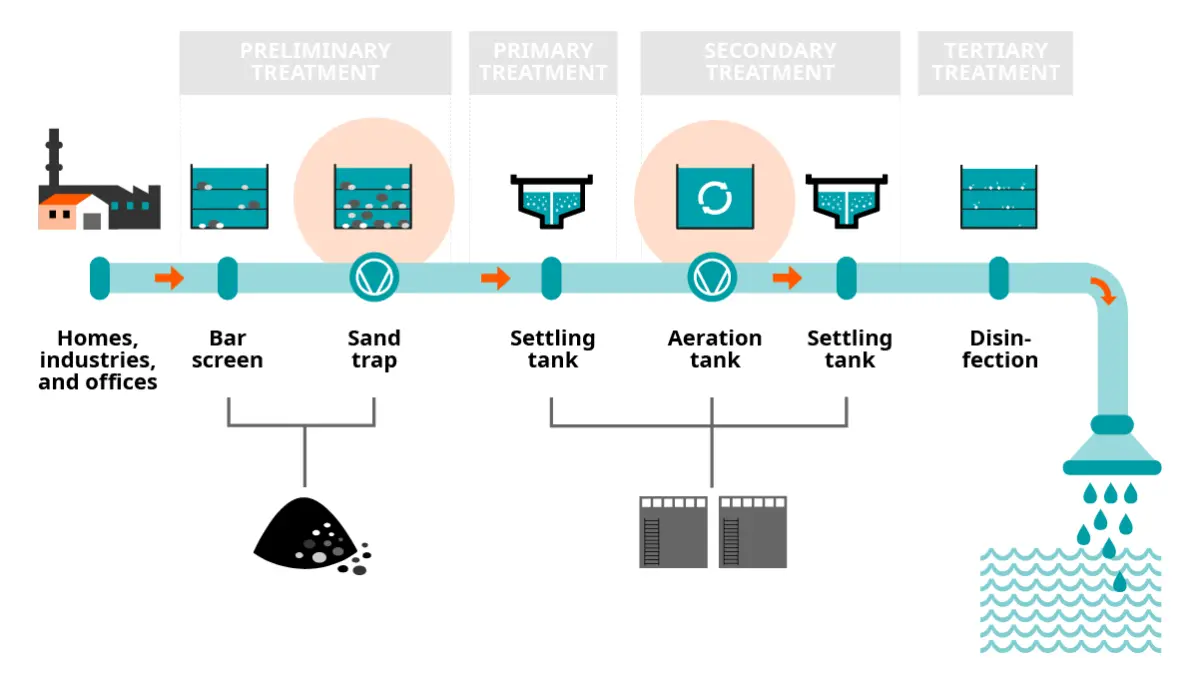

Wherever there are built-up areas, there is wastewater. This comes from all kinds of buildings – homes, offices, shops and industries – as well as from the streets after rain or snowfall. Municipal wastewater makes its way into drains, passes through the sewer system, and arrives at the treatment plant. There, a series of treatments await before it can re-enter natural waterways.The main stages involved are filtration and aeration.

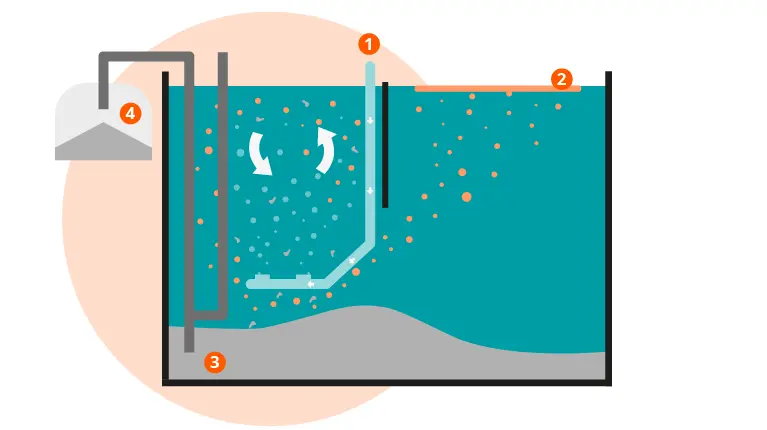

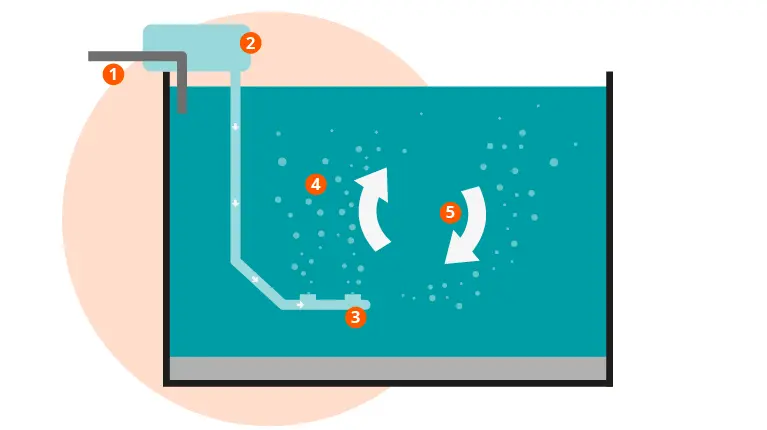

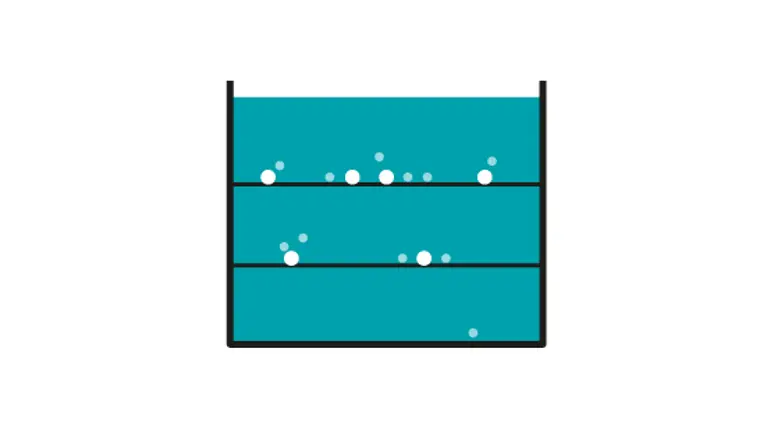

Aeration plays an essential role in municipal wastewater treatment. By continuously introducing oxygen into the wastewater, the naturally occurring microorganisms that break down the organic waste are stimulated and can work more efficiently.

This results in cleaner water over a shorter period of time, which can then be released safely back into nature.