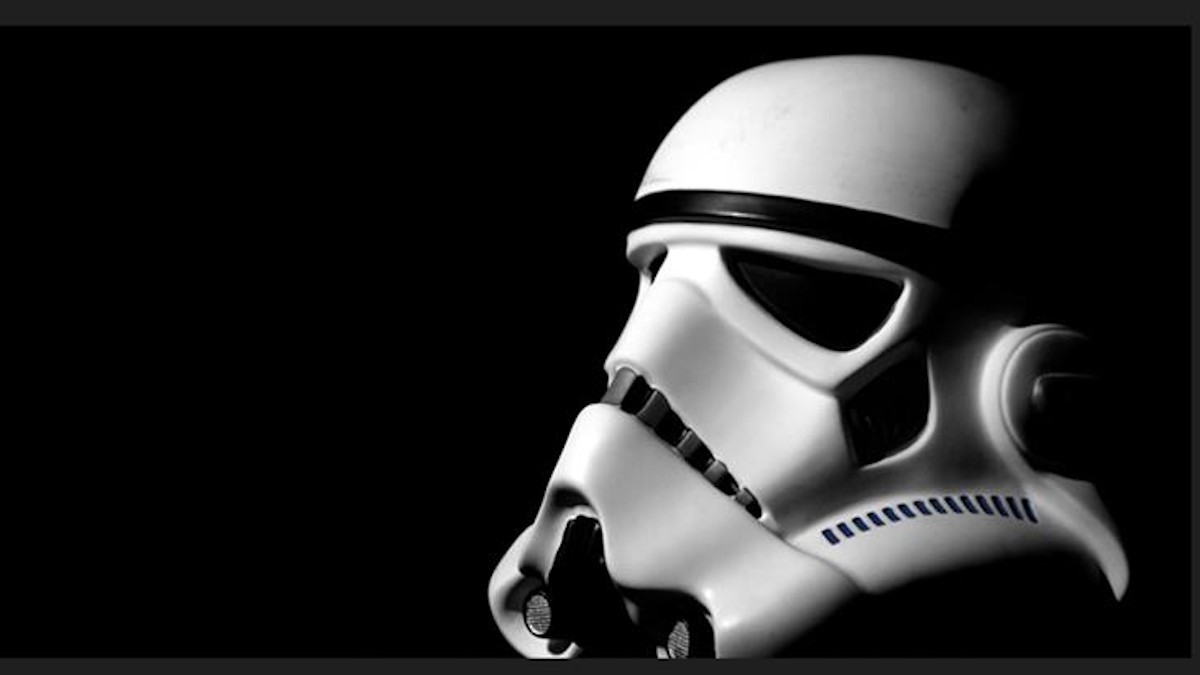

Original stormtrooper hero imperial helmet. Source: petter005 – shutterstock.com.

Star Wars Merchandise Thanks to Efficient Vacuum Technology

Stormtrooper helmets made with the help of vacuum

It all began in 1977 with the original Star Wars film and the battle of the dark side of the Force against the light side. Since then, the Star Wars empire has developed rapidly. In addition to numerous films and series, there are also endless merchandise products that have a high demand around the world. Such as the original stormtrooper helmets made with the help of our R5 rotary vane vacuum pumps.

Star Wars has become a valuable brand over the years. Fans all over the world spend a lot of money on fan merchandise. This is also the case for the original stormtrooper helmets. These are still handmade today in Twickenham in England and have a high emotional value for collectors all over the world. Our vacuum technology is used in the production of the plastic helmets. With the help of our R5 rotary vane vacuum pumps, the helmets are molded from plastic.

Sporting Composites Ltd produces the stormtrooper hero helmets in the Shepperton Design Studios to this day using the original form of 1976. At that time, the original helmet was made by Andrew Ainsworth for the first Star Wars movie. The helmets are still made by hand and even hand painted. Six employees work at the factory in Twickenham and produce not only the stormtrooper helmets but also original Star Wars armor and props.

The hero helmets are made of two-millimeter-thick ABS and are cast in the original molds of yesteryear. To date, the helmets are not completely symmetrical. This can be attributed to the fact that when the mold was made in the 70s, there were neither CNC machines nor AUTO-CAD. The mold consists of two parts, which at the time when casting the helmet for the Star Wars movie did not fit one hundred percent on each other. But since Andre Ainsworth only had two days until the start of filming, he shaved off one side by hand until the two halves fit together. And so, the asymmetrical original helmet was created, whose characteristic shape has not been changed to this day with the help of modern CAD programs.

When molding the ABS helmet parts, it is crucial that a clearly defined vacuum is applied to gently pull the material into shape. Since the helmets are only two millimeters thick, vacuum technology is critical to the quality of the molded parts.

Sporting Composites Ltd produces the stormtrooper hero helmets in the Shepperton Design Studios to this day using the original form of 1976. At that time, the original helmet was made by Andrew Ainsworth for the first Star Wars movie. The helmets are still made by hand and even hand painted. Six employees work at the factory in Twickenham and produce not only the stormtrooper helmets but also original Star Wars armor and props.

The hero helmets are made of two-millimeter-thick ABS and are cast in the original molds of yesteryear. To date, the helmets are not completely symmetrical. This can be attributed to the fact that when the mold was made in the 70s, there were neither CNC machines nor AUTO-CAD. The mold consists of two parts, which at the time when casting the helmet for the Star Wars movie did not fit one hundred percent on each other. But since Andre Ainsworth only had two days until the start of filming, he shaved off one side by hand until the two halves fit together. And so, the asymmetrical original helmet was created, whose characteristic shape has not been changed to this day with the help of modern CAD programs.

When molding the ABS helmet parts, it is crucial that a clearly defined vacuum is applied to gently pull the material into shape. Since the helmets are only two millimeters thick, vacuum technology is critical to the quality of the molded parts.