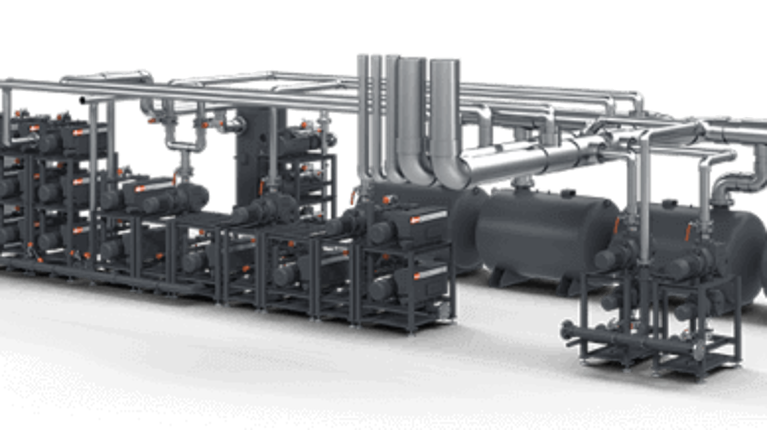

One central vacuum system. Countless benefits.

Depending on the application, energy savings of up to 70 % can be achieved with a central vacuum system. And this is not the only benefit.

Busch is the leading provider of customized vacuum and overpressure systems. We have more than 50 years of experience in designing and building tailor-made systems for all industries.

The central vacuum system installed by Busch ensures smooth day-to-day production. Since the commissioning of the system, failures as well as bottlenecks in vacuum availability are no longer an issue.

Installing a Central Vacuum system vs. Decentralized Vacuum System

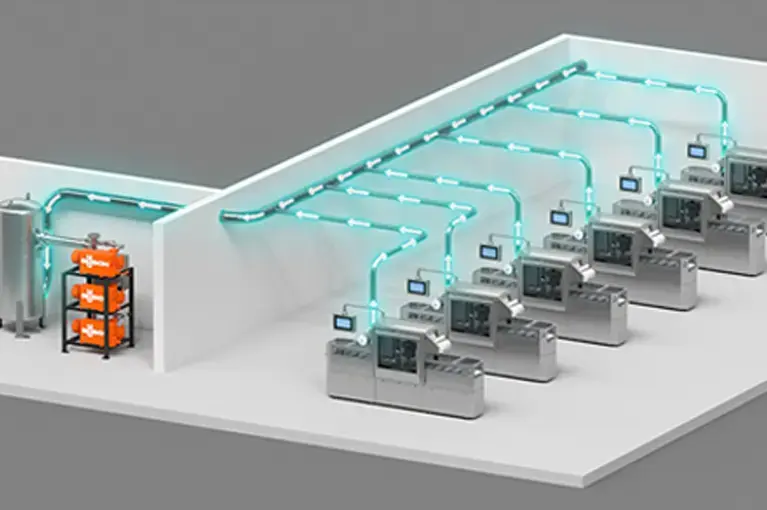

Most vacuum processes are decentrally supplied with vacuum. Each machine which requires vacuum is equipped with its own vacuum pump. These vacuum pumps are always operating at full power consuming a lot of energy.A centralization of the vacuum supply should be considered if multiple processes or machines require vacuum. Compared to a decentralized supply, central vacuum units generally require lower pumping speed, which results in fewer vacuum pumps.

Not all applications require the maximum possible pumping speed at the same time. Central vacuum systems are controlled on a demand-driven basis. This means that switching individual vacuum modules on and off enables the vacuum system’s performance to be adapted to overall demand. As a result, high energy savings can be achieved.

Before installing a central vacuum system, all relevant parameters must be evaluated individually. Depending on the specific process requirements, the perfect solution can be defined.

BENEFITS OF CENTRAL VACUUM SYSTEMS

Significant savings

- Demand-driven control

- Easier and faster maintenance during normal working hours

- Heat recovery (50-70 % of energy consumption)

- Reduced demand for air conditioning (if applicable)

Increased productivity

- Lower required pumping speed, resulting in a reduced number of vacuum pumps

- High uptime and reliability because of stand-by vacuum modules

- Long lifetime thanks to evenly distributed workload

- Higher flexibility due to on-demand vacuum, expansion of system often possible

Improved working environment

- Set up in special equipment rooms, separate from production areas

- No noise emissions in production area

- Lowest heat emissions in production area

- Clean working environment in production area (e.g. no contact with hygienically sensitive zones during maintenance work)

WHERE TO USE CENTRAL VACUUM SYSTEMS

-

Vacuum packaging

Vacuum packaging is a method of packaging that removes air from the package prior to sealing.

This method involves (manually or automatically) placing items in a plastic film package, removing air from inside and sealing the package. Vacuum enhances product quality and increases productivity.

-

Handling applications

In modern production processes, holding, transporting, lifting and handling goods is done by vacuum.

The idea is as simple as ingenious: A suction cup, vacuum plate or vacuum table is used to apply suction and to hold an object firmly.

This is an extremely effective method that makes it possible to move, transport or clamp objects held in this way.

-

Woodworking processes

In wood processing vacuum is used in a variety of applications, such as clamping, laminating and veneering, drying, handling and lifting.

-

Medical vacuum supply

Reliable and safe support systems are indispensable in modern healthcare. Medical vacuum and air supply systems are no exception.

For hospitals, dental clinics, laboratories and other healthcare institutions, it is important to have individual solutions. Manufactured and certified to conform to all national and international standards. For the health of the patients.

FAQ

How do I know if a central vacuum system makes sense for my process?

Generally speaking, the more vacuum consumers, the more economical a central vacuum system is. However, this can only be a rule of thumb. Expert evaluation is needed as there are many parameters to be considered. Sometimes even in a plant with only two vacuum pumps a central vacuum system can be worthwhile.

Is there a "one size fits all" solution?

Definitely not.

It is always important to evaluate all parameters individually to find the perfect solution for the specific process requirements. Sometimes a standardized approach, which is easy to install can be used. Sometimes a partial centralization is recommended. While in another situation, a tailor-made system that is perfectly adapted to individual needs fully exploits the potential benefits. This weighing can only be carried out by a specialist with many years of experience.

Why should Busch be my partner of choice?

Busch is the number 1 worldwide for innovative vacuum systems in all industries. Every project incorporates more than 50 years of experience in the design and construction of tailor-made systems. All systems are manufactured in dedicated Busch systems building centers located around the world. We provide turnkey systems, including installation of pipework and control units. Start-up service and training for the operating team are also on offer.