Of the seven basic units, the kilogramme is the only remaining unit still based on an object that really exists: the International Prototype of the Kilogramme (IPK) stored in Paris. This is expected to change soon; the new definition of the unit of mass will be based on natural constants. Essential steps in the experiments required to do this take place in a vacuum.

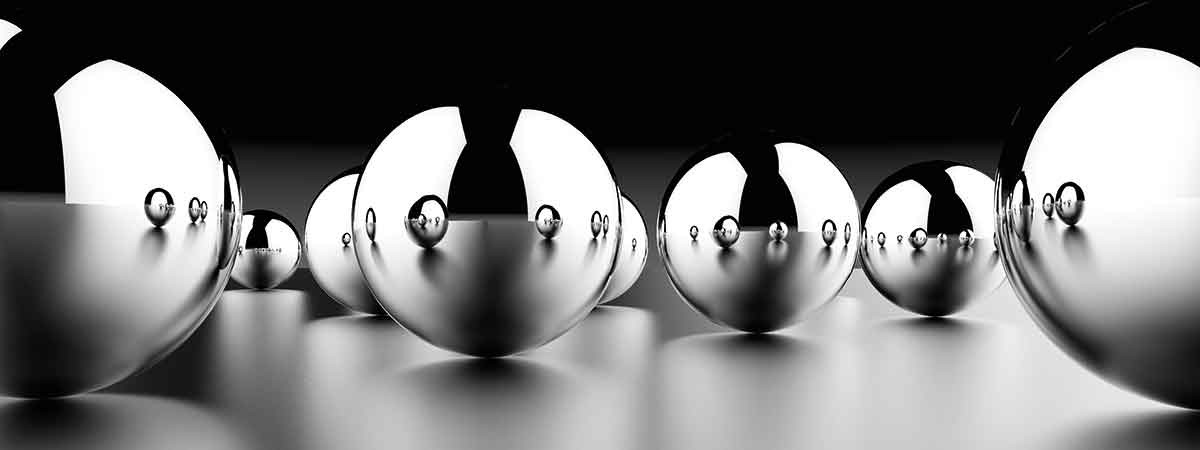

About the size of a tennis ball, silvery, and a nearly perfect spherical shape – that is what the crystal spheres look like that could soon replace the platinum-iridium cylinder of the IPK in Paris. Scientists have made it from highly purified silicon; its weight exactly corresponds to that of the prototype kilogramme.

Lighter in a vacuum

To compare the mass of the silicon sphere with the prototype kilogramme, the objects are weighed under atmospheric conditions as well as in a vacuum. Since measurements in a vacuum are not hindered by air buoyancy and the effects of convection, the measurement results do not vary as much as they do at atmospheric pressure. Bodies in a vacuum are also a little bit lighter because tiny particles from the air can form deposits on the surface of the objects. When weighing the crystal spheres, these particles can in fact make an average difference of nearly ten micrograms.

To create an unbiased formula for defining the kilogramme, the physicists must subsequently determine the number of silicon atoms in the spheres. Thanks to the extremely precise spherical form and the perfect crystal structure, this can be very precisely calculated. But to achieve the required precision, the researchers may only miscount by a maximum of one atom in one hundred million atoms. If the experiment is successful, it will also be possible to base the kilo on a natural constant: the atomic weight of silicon-28.

Vacuum ensures purity

To precisely determine the number of atoms, the silicon has to be extremely pure. The monocrystalline solid is thus grown in a vacuum to ensure flawless quality. To do this, purified, homogeneous silicon is heated in a crystal pulling plant crucible to a few degrees above the melting point. A small, highly purified single crystal – known as the seed crystal – is then dipped into the molten mass. The liquid silicon solidifies on the seed crystal and continues building its regular lattice structure in the process. Slow rotational and upward movements cause a cylindrical crystalline pillar to form; the silicon spheres are then cut from this.

The thus manufactured and subsequently polished spheres are nearly perfectly formed: their diameters do not vary by more than one hundred nanometres at any place on the sphere's form. If we were to transfer these proportions to the earth, no hill would be more than five metres high.

Two years of measurements

To determine the volume, approximately one million points on the surface of the silicon spheres must be precisely optically measured. The distance between the individual atoms in the crystal lattice is determined using an X-ray interferometer. Once this data is known, the number of atoms that fit into that volume can be calculated – in theory.

Because while the inside of the silicon spheres consists of a regular crystal lattice, a layer of silicon dioxide builds up on the surface. It influences the mass and the volume of the spheres, which is why its thickness has to be precisely determined and taken into account by the physicists. The spheres are thus analysed using a combination of X-ray fluorescence spectroscopy and photoelectron spectroscopy. This analysis also takes place in a vacuum: the spheres are analysed in an ultra-high vacuum system at a vacuum of approximately 10-8 mbar so the photons and electrons are not absorbed by air particles and instead reach the detector unhindered.

The researchers have planned approximately two years for measuring the crystal spheres. After nearly 130 years of use, the prototype kilogramme may be replaced in autumn 2018.

Redundant prototype kilogramme

Vacuum technology plays an important role in the new definition of mass

Why should the prototype kilogramme be replaced?

Nowadays, most units of measure are determined using formulas with unchanging natural constants. So, for example, the metre is defined as the distance that light travels in a vacuum in one 299,792,458th of a second, the second being the period of time in which a caesium atom oscillates 9,192,631,770 times.

The prototype kilogramme is losing weight

In contrast, the kilogramme is the only unit of measure still based on a real mass, the prototype kilo. This has its problems because if this prototype is damaged or lost, it cannot be replaced. The platinum-iridium cylinder is also losing weight over time: it has become approximately 50 micrograms lighter since it was made. This was discovered by comparing it to its copies, which are distributed across measuring institutes worldwide. The reason for this loss of mass has not been conclusively resolved; one possible cause may be the cleaning procedure. With a new definition of mass based on natural constants, this kind of problem would become a thing of the past: an exact one-kilo reference mass can then be reproduced at any time if needed.

Nowadays, most units of measure are determined using formulas with unchanging natural constants. So, for example, the metre is defined as the distance that light travels in a vacuum in one 299,792,458th of a second, the second being the period of time in which a caesium atom oscillates 9,192,631,770 times.

The prototype kilogramme is losing weight

In contrast, the kilogramme is the only unit of measure still based on a real mass, the prototype kilo. This has its problems because if this prototype is damaged or lost, it cannot be replaced. The platinum-iridium cylinder is also losing weight over time: it has become approximately 50 micrograms lighter since it was made. This was discovered by comparing it to its copies, which are distributed across measuring institutes worldwide. The reason for this loss of mass has not been conclusively resolved; one possible cause may be the cleaning procedure. With a new definition of mass based on natural constants, this kind of problem would become a thing of the past: an exact one-kilo reference mass can then be reproduced at any time if needed.