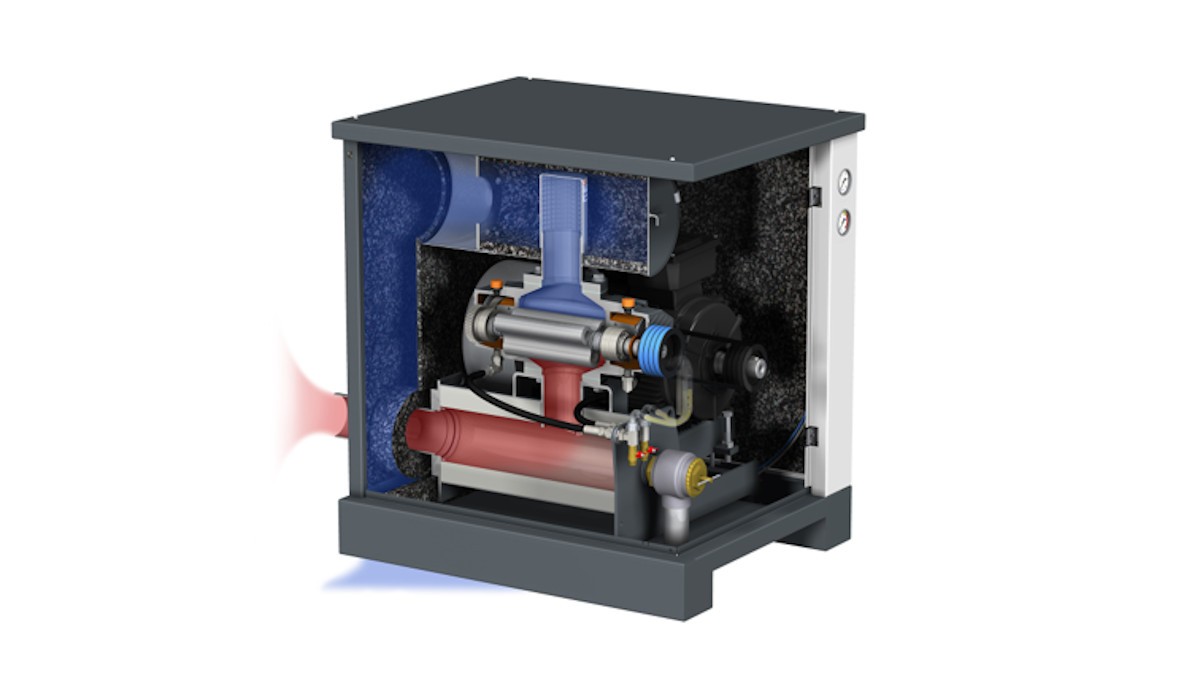

Fig. 1: Two of the four TYR rotary lobe blowers used for oxygenation of the water and cleaning the filtration stages. Source: Busch Vacuum Solutions.

Perfect Water Treatment Thanks to Adjustable Rotary Lobe Blowers

23,000 inhabitants of the Danish municipality of Rudersdal are supplied with drinking water by the municipal water company Birkerød. The annual consumption for this area is 1.2 to 1.5 million cubic meters of water. The raw water is pumped from nine deep wells with an average output of 160 cubic meters per hour.

TYR rotary lobe blowers from Busch Vacuum Solutions are used for treating raw water to prepare it as drinking water.

Water treatment from raw water to drinking water is a two-stage process. The raw water is aerated in a first step. This removes unwanted gases such as methane or hydrogen sulfide from the water. The water is also enriched with oxygen in the same process step. This is done so that, after filtration, the drinking water contains the specified five milligrams of dissolved oxygen per liter.

In order to obtain the most energy-efficient solution, those responsible opted for two TYR rotary lobe blowers from Busch Vacuum Solutions These blowers adapt their performance to the incoming raw water quantity by means of variable speed drives, so that it can be guaranteed that the oxygen content in the water is always the same.

In the past, the raw water was enriched with oxygen via so-called oxygen stairs. The disadvantage of this procedure is that there are no adjustment options, i.e. the oxygen content could not be maintained precisely. In addition, high cleaning and maintenance effort was also required.

When the water treatment plant had to be overhauled in 2018, the water company Birkerød decided to install floor aeration in two lines and, in cooperation with Busch Vacuum Solutions, installed two frequency-controlled TYR rotary lobe blowers (Fig. 1). The water is aerated in two identical aeration tanks. Only one of these systems is in operation at a time. The second has a pure stand-by function to ensure the water supply in case the other system fails. Normally, both aeration systems are used daily on an alternating basis. A TYR rotary lobe blower is connected to each of these aeration tanks. A silencer is mounted on the inlet side in order to keep noise emissions inside and outside the building as low as possible. For plant manager Jens Ejnar Kristensen, the smooth running of the rotary lobe blowers was an extremely important aspect, given that the water treatment plant is located in the middle of a residential area. Since the installation of the two TYR rotary lobe blowers in these aeration systems, Kristensen has been able to precisely maintain the oxygen content and thus ensure a consistently high-water quality.

After aeration, the second step involves filtering the water through sand filters. The filtration takes place in two stages: in pre-filters and after-filters. The sand filters remove iron and manganese from the water and convert ammonium into nitrate. The filters must be cleaned of sand deposits at regular intervals. For this purpose, compressed air flows through them, which is generated by two TYR rotary lobe blowers. These rotary lobe blowers are equipped with frequency-controlled motors, meaning that the performance is adapted to the degree of clogging of the filters. At the same time, the flow rate or pressure is prevented from being too high so that the differently grained sand layers are not swirled together.

Two TYR rotary lobe blowers have also been in use here since 2017 in order to regenerate the six pre-filters and the six after-filters. At that time, they replaced two obsolete rotary lobe blowers that required a great deal of maintenance and needed to be changed out, as they were too old. TYR rotary lobe blowers are equipped with an acoustic enclosure as standard.

The rotary lobe blowers originally used were unregulated. This meant it was not possible to adjust the volume flow and overpressure to the actual demand. Jens Ejnar Kristensen determined that optimizing the aeration process results in significant energy savings. In addition, the water company Birkerød was able to adjust the flushing of the filters based on the individual filter sizes and depending on whether they were pre-filters or after-filters.

After the raw water has been filtered, it is fed into a 1,000 cubic meter clean-water tank, from where it is pumped into the distribution network directly to the consumer or in a water tower as a reservoir.

With the complete conversion to frequency-controlled TYR rotary lobe blowers, the water company Birkerød has succeeded in modernizing its waterworks and achieving consistently high water quality over the long term, while at the same time saving energy.

-

Fig. 2: The TYR rotary lobe blowers are equipped with acoustic enclosures and variable speed drive. Source: Busch Vacuum Solutions.