What is wastewater treatment?

Wastewater treatment describes any method used to remove contaminants so that the resulting effluent can be reintroduced safely to the natural environment. The exact methods and the extent to which the water is treated depend on the type of wastewater and the facility. Many of these methods use overpressure for circulation and aeration to increase the efficiency of the treatment process.Overpressure expertise for efficient wastewater solutions

In the field of wastewater treatment, overpressure solutions play a pivotal role in enhancing operational efficiency and reliability. Compressors and blowers are designed to optimize air flow within the treatment processes, particularly in aeration and circulation systems. These introduce oxygen in the activated sludge process – the biological process that breaks down dissolved contaminants in municipal wastewater – and ensure that it is distributed evenly throughout the tank. By precisely controlling the overpressure, these solutions reduce the energy consumption and maintenance requirements of the wastewater plant.Our expertise in overpressure technology has supported continued enhancements in the wastewater industry. The optimal technology increases the efficiency of oxygenation in aeration tanks, enhances the separation efficiency in sand traps, and boosts biogas production.

Read more about overpressure solutions for wastewater processing.

Types of wastewater treatment plants

There are several different types of wastewater treatment plants, with slightly varying processes optimized to best treat a certain type of wastewater.- Municipal wastewater treatment plants: These treatment facilities process domestic wastewater, namely sewage from households and businesses as well as run-off from streets. They may also accept pre-treated industrial wastewater. Municipal plants can be found in settlements throughout the world, and usually consist of a minimum of primary and secondary treatment stages, with most incorporating an additional tertiary treatment to purify the final effluent.

- Industrial wastewater treatment plants: These plants are specifically built to handle the wastewater generated by industry, such as food and beverage processing, or the manufacture of chemicals and pharmaceuticals. The treatment facilities can be customized to treat the specific pollutants that a certain industry creates, such as to remove or neutralize toxic substances or remove organic matter.

- Agricultural wastewater treatment plants: Agricultural operations also produce wastewater that cannot enter the municipal system untreated. These plants treat animal slurry and surface run-off from fields, which can be contaminated with fertilizers and pesticides.

- Leachate treatment plants: This plant treats the challenging wastewater from landfill sites. Known as leachate, this is a thick liquid run-off that forms when rain percolates through the accumulated waste, picking up and dissolving chemicals as it makes its way through the layers.

The six stages of wastewater treatment

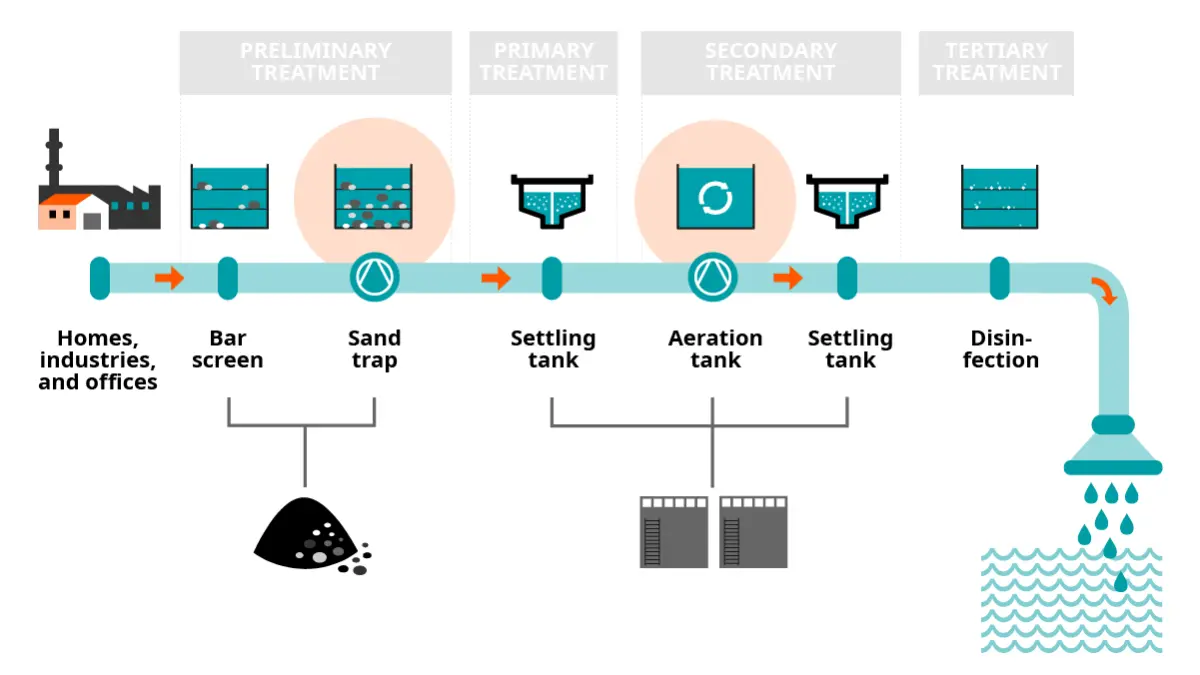

Each type of treatment plant follows a slightly different procedure in order to make the wastewater it is processing safe. However, many of the individual stages are the same. The six stages described below are those typically used in the most common treatment facility: municipal wastewater plants.1. Wastewater collection: The first stage in the wastewater treatment process involves its collection. Wastewater from homes, offices, shops, and certain industries, as well as from street drainage systems, travels through a network of sewers to the municipal treatment plant. Industrial, argricultural, and leachate treatment plants typically have shorter journeys, as they tend to be treated on site. In some cases, industrial effluent is pre-treated and then continues to the municipal treatment plant for final processing.

2. Preliminary treatment: The treatment process begins with an essential screening stage. Bar screens intercept large objects that have found their way into the drainage systems, such as rubbish, items of clothing or branches. Sand traps – also known as grit chambers or grit removal tanks – are instrumental in allowing smaller particles, like sand and gravel, to settle and be removed. This stage can be accelerated and made more efficient by the use of blowers. These circulate the water, encouraging the heavier debris to fall to the bottom and the lighter parts to remain in suspension. In doing this, sludge build-up is prevented, ensuring that the waste is better separated. This has several advantages: By removing the grit and sand, damage to downstream equipment and pipes can be prevented, also reducing the frequency and cost of maintenance. It also ensures that the later processes need only treat organic matter, which ultimately improves the quality of the final effluent.

Learn more about sand traps.

3. Primary treatment: Settling tanks play a vital role in separating solids from liquid. In the primary sedimentation stage, the solids that remain after the screening processes slowly sink to the bottom of the tank. There, they form a sludge that can be removed and be disposed of.

4. Secondary treatment: Secondary treatment is the main purification stage. Also known as activated sludge, this is a biological process that makes use of the large ecosystem of microorganisms naturally present in wastewater. These digest the organic compounds dissolved in the water, as well as any suspended particles that made it through the previous processes. As the microbes eat, they multiply, forming large colonies that can subsequently be filtered out as solids in the secondary settling tank. However, for this process to work effectively, the bacteria need a high concentration of oxygen in the tank. A blower or compressor introduces a steady stream of air bubbles via diffusers, increasing the oxygen levels that the bacteria needs to thrive. The movement these air bubbles create also circulates the waterwater to ensure that the oxygen is equally distributed.

Read more about aeration.

5. Tertiary treatment: The water has now been treated but can still contain a small amount of harmful pathogens and bacteria. As a result, many wastewater treatment plants include a disinfection process, leaving behind water that can be safely reintroduced into public water supplies or sensitive aquatic ecosystems. The water may undergo ultraviolet treatment, or be mixed with chlorine and subsequently dechlorinated. Then it can be released.

6. Sludge treatment: This stage processes the sludge collected during primary and secondary treatment. The ultimate usage for the final product dictates how it is treated – it may be incinerated, sent to landfill, or used as a fertilizer. One method to reduce the amount of sludge is sludge digestion, a process that – like the activated sludge process – makes use of the natural microorganisms present in the sludge. These digest the sludge, generating a renewable and sustainable by-product that can be used to generate power: biogas, a mixture of methane and carbon dioxide. Overpressure plays an essential role in the digester tank by circulating the biogas. As the microorganisms produce biogas, it bubbles up to the top of the tank. There, it is suctioned out and compressed using a compressor. The majority is subsequently stored or injected into the gas grid. However, part of the gas is heated and reinjected to the bottom of the tank, forming bubbles. These make their way back up through the sludge, and the process repeats. In doing this, the sludge in the tank is kept in constant movement, ensuring that heat, solids, and the bacteria are evenly distributed. This ultimately enhances the efficiency of the process.

Learn more about biogas circulation.

Read about how power is generated in a wastewater treatment plant.