Vacuum Pumps in the UK

Whether providing a reliable central vacuum supply for a hospital in

London or supplying vacuum pumps for packaging to leading food production companies in

Birmingham, Busch is the number one supplier for vacuum solutions in

England, Wales and Scotland.

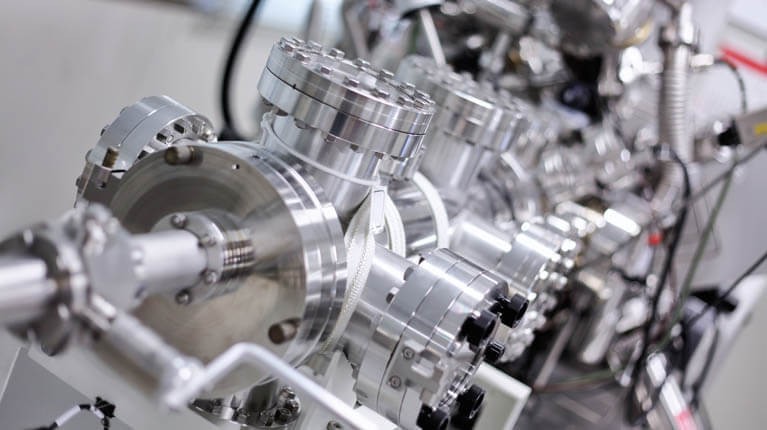

The Semiconductor industry is a major employer in

Manchester and is supported by leading high vacuum expertise and products from Busch. Shipbuilding continues to thrive in Scotland's most populated city,

Glasgow. Vacuum is replacing towing ropes as a quicker and more secure ship mooring system.

Newcastle's Centre for Life is a science village established in 2000 to promote the advancement of biotechnology. So-called laboratory vacuum pumps from Busch are used routinely in labs across the UK.

To this day,

Sheffield has an international reputation for steelmaking and metallurgy. Vacuum is used in many processes in the metallurgical sector including alloy production, single crystal fabrication, steel degassing and annealing by heat treatment.

Leeds is the third largest manufacturing center in the UK with meat production playing a major part. There are numerous applications in UK's food industry that rely on vacuum like the processing of heat- and oxygen-sensitive materials.

Bristol has been playing an important role in the manufacture of aircraft for decades. A new aluminium alloy enables a lot of weight to be saved in the aviation sector. Vacuum is used in a process called creep age forming which puts the construction material into shape.

Nottingham included low-carbon technologies in their economic development strategy. Many of those technologies like the production of solar panels or wind turbines use Busch vacuum in their production processes.

Car manufacturing takes place in the

Liverpool area with British luxury cars being assembled in the city of Halewood. Vacuum technology allows the reliable, safe, and efficient handling of parts in the assembling process. Invisible to the eyes of many, thousands of Busch vacuum pumps are in operation in many sectors of the British economy in all corners of the country.

Busch group