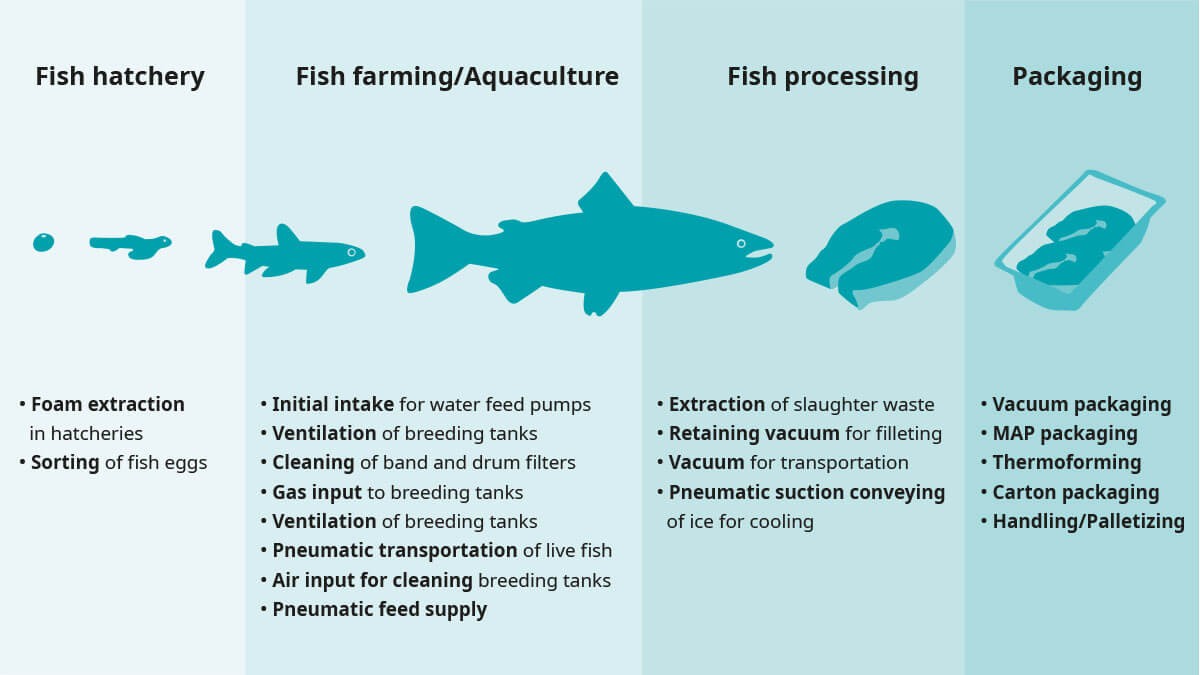

Fish hatchery

- Foam extraction

- Sorting of fish eggs

During the first year, the salmon fry is living in cages indoors.

In this time, the fish is closely monitored with cameras. Specialized personnel, often veterinarians, make sure that the fish fry is fed adequately. And that the oxygen level inside the water is maintained at an appropriate level. The supply of additional oxygen to the breeding tanks can, for example, be ensured by rotary lobe blowers of the TYR family.

Moreover, the size of the salmon fry is constantly monitored as it is important that they grow in a comparable way. Otherwise, some fish that dominate in size will get stronger and larger while smaller ones have difficulties to survive. To avoid this imbalance, the fish are sorted in regular intervals. Vacuum allows to gently move the live fish from one tank to another via pneumatic conveying.

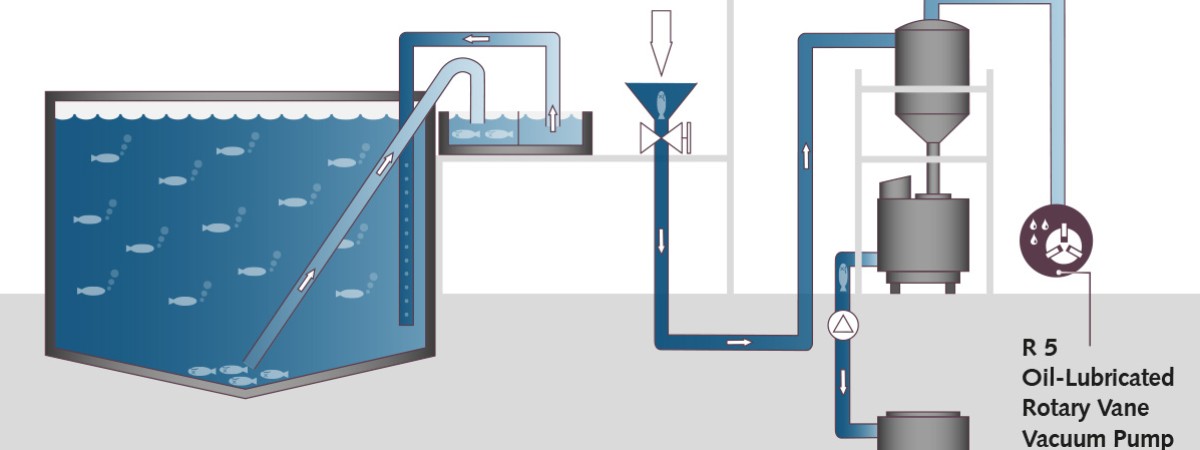

Some fish unfortunately do not survive the initial breeding phase in the indoor tanks. It is important to regularly remove this dead fish to prevent diseases and ensure maximum hygiene. Dead fish sink naturally to the bottom of the cages. There, they are picked up with a hoof and placed in a funnel next to the cage. This funnel is opened with a valve and the dead fish are suctioned out of the premises by means of vacuum. This so-called "dead fish removal system" is one of our most popular standard vacuum systems.