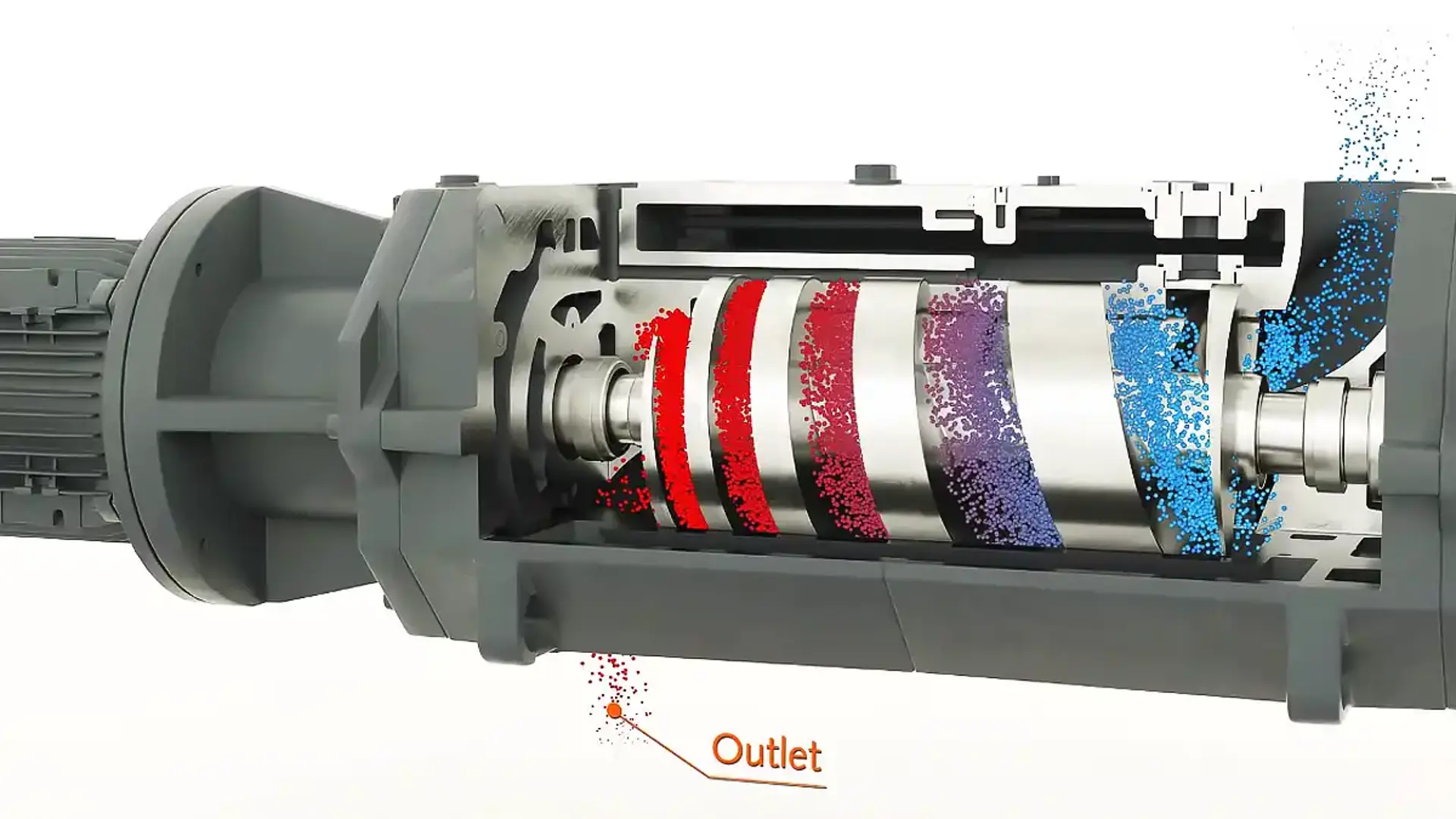

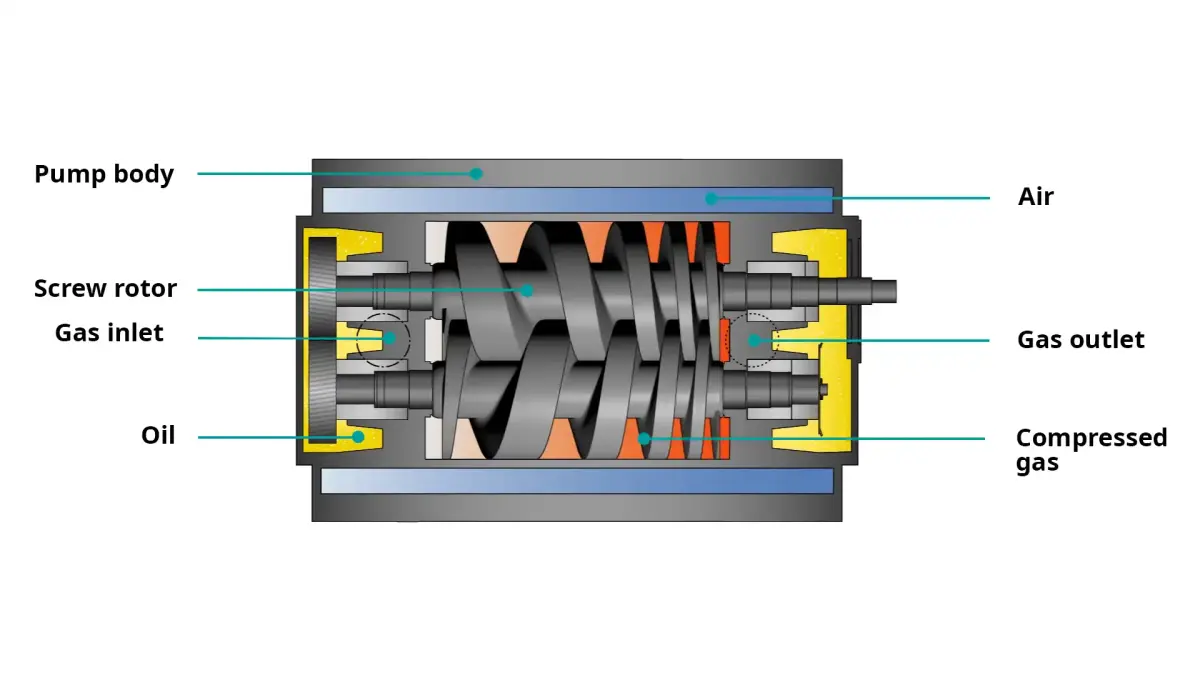

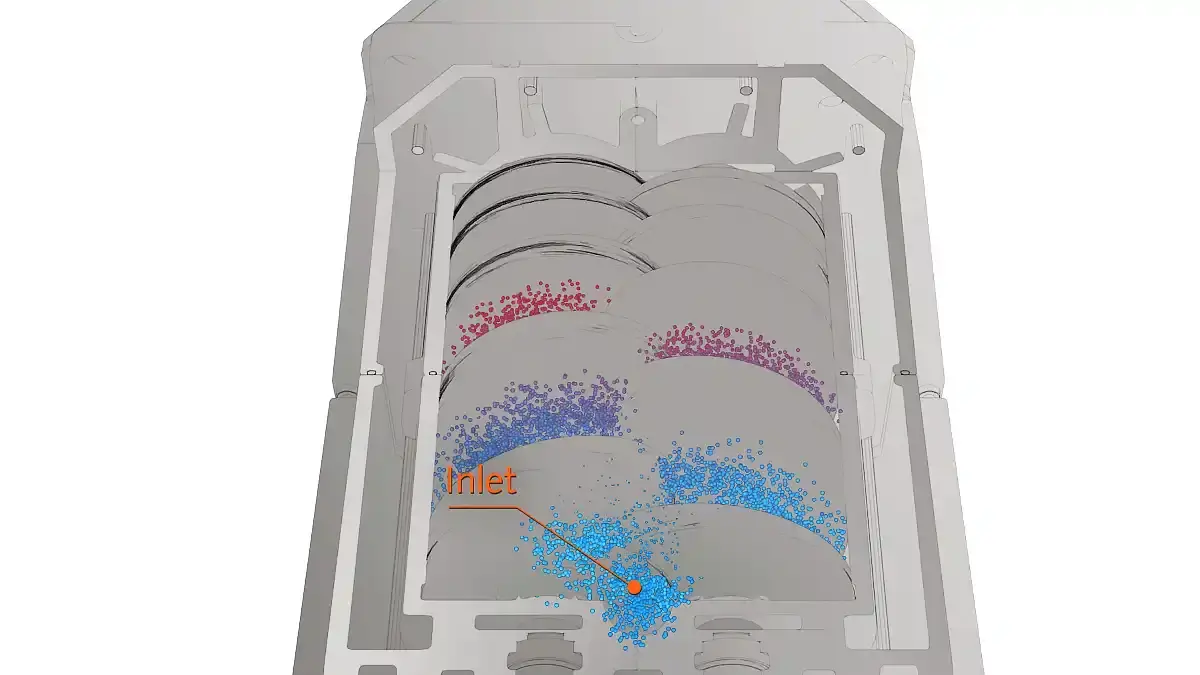

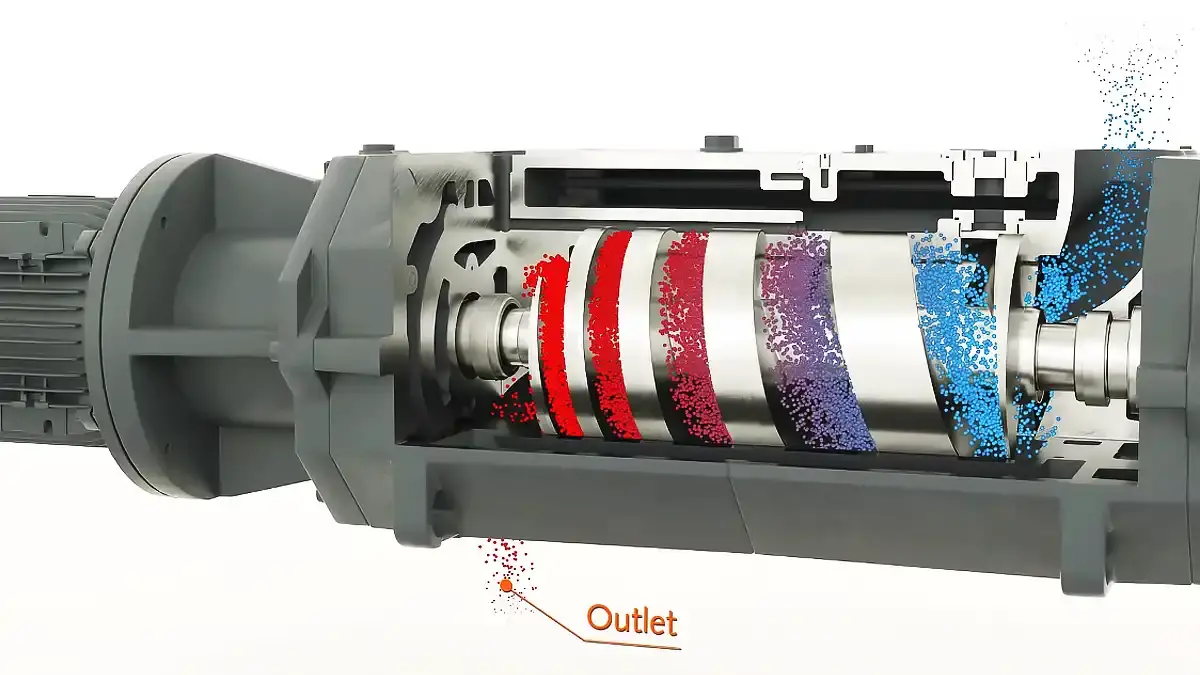

Types de pompes à vide sèches à vis

Les pompes à vide sèches à vis COBRA Industry conviennent parfaitement pour les applications industrielles qui requièrent une extraction des gaz et vapeurs fiable et sans contamination.Vous recherchez une pompe à vide sèche à vis pour des processus exigeants, tels que le revêtement ou la fabrication de semi-conducteurs ? Découvrez les pompes COBRA Semicon de Pfeiffer Vacuum+Fab Solutions (membre du Busch Group).

Série de produits | Vitesse de pompage nominale |

|---|---|

COBRA NX | 350 m³/h à 950 m³/h |

COBRA NC | 110 m³/h à 2 500 m³/h |

COBRA NS | 70 m³/h à 600 m³/h |

COBRA NF | 750 m³/h à 950 m³/h |

COBRA DX PLUS | 650 m³/h à 1 900 m³/h |

COBRA DS | 70 m³/h à 1 640 m³/h |

COBRA DH | 2700 m³/h à 6200 m³/h |

COBRA BA | 85 m³/h à 105 m³/h |