Types of dry claw vacuum pumps

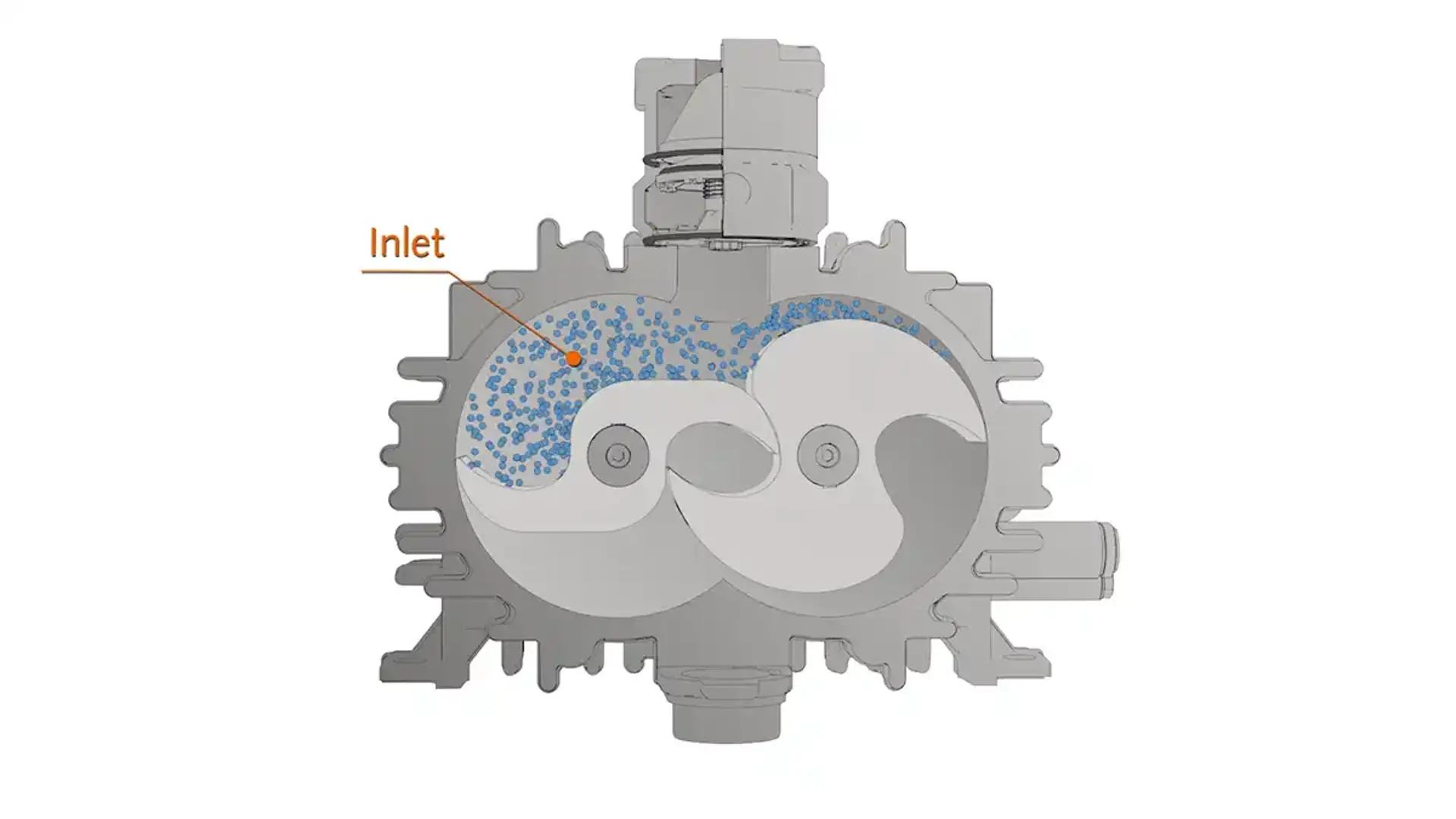

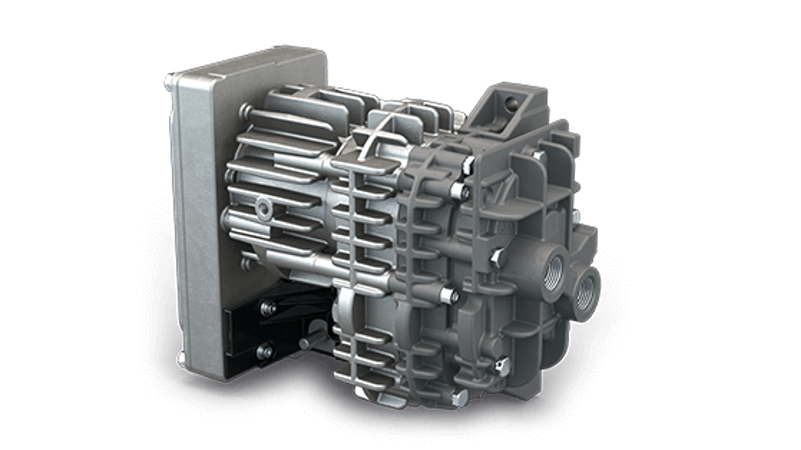

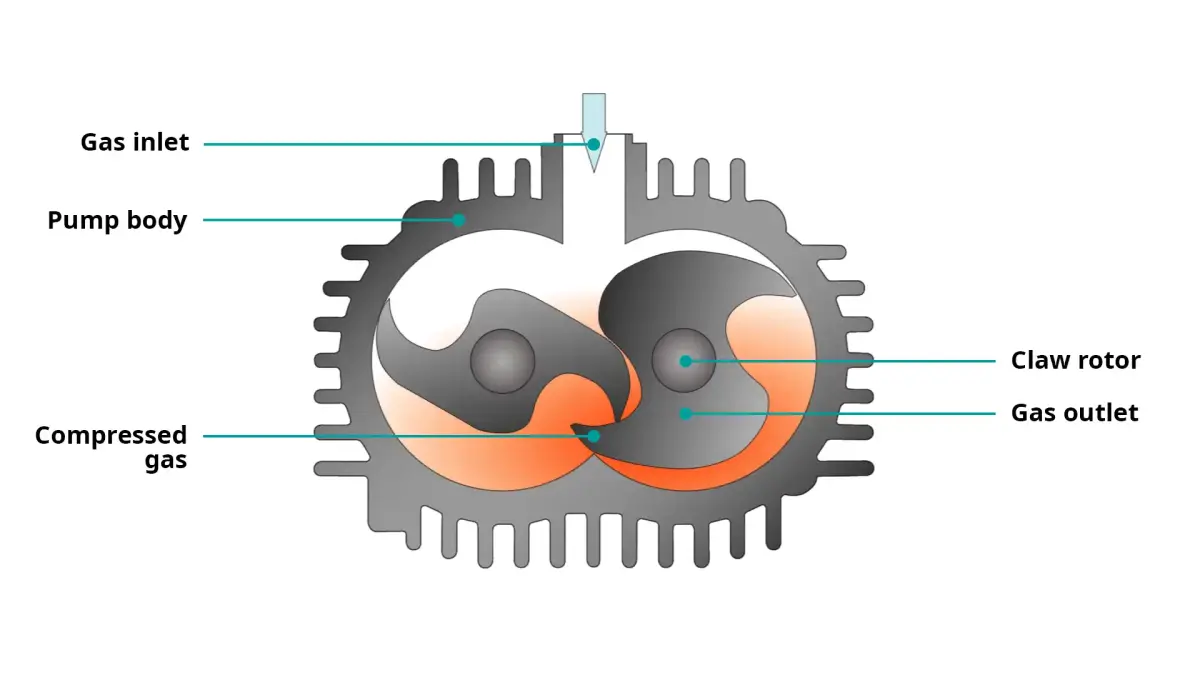

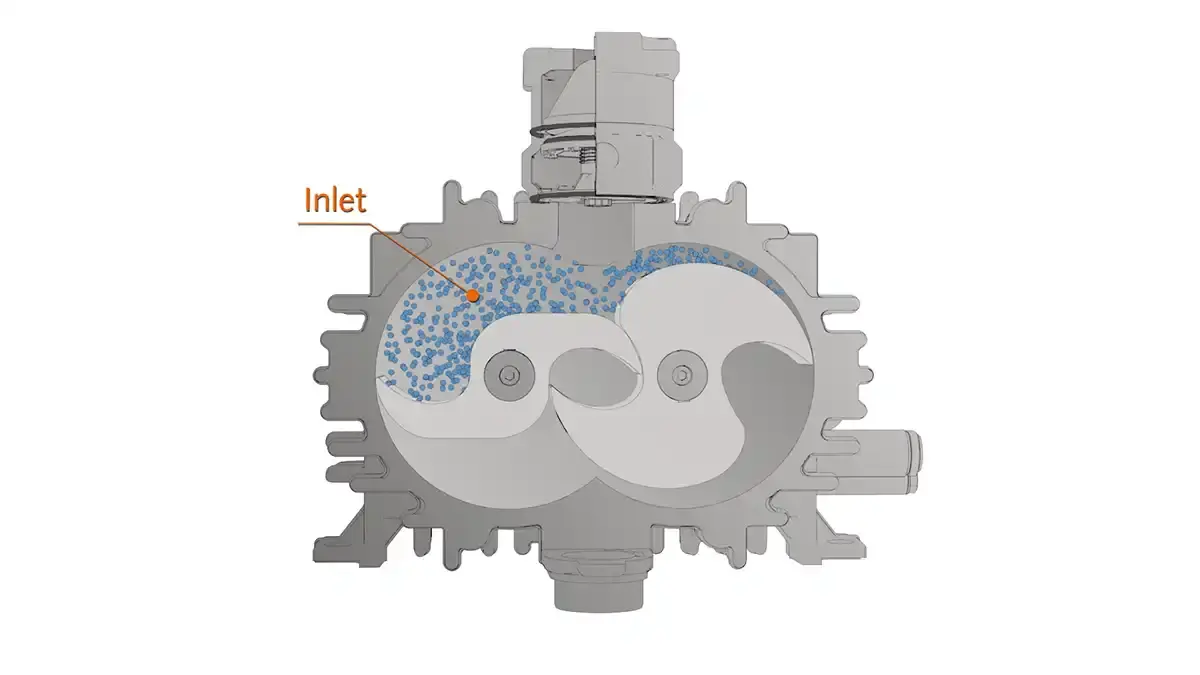

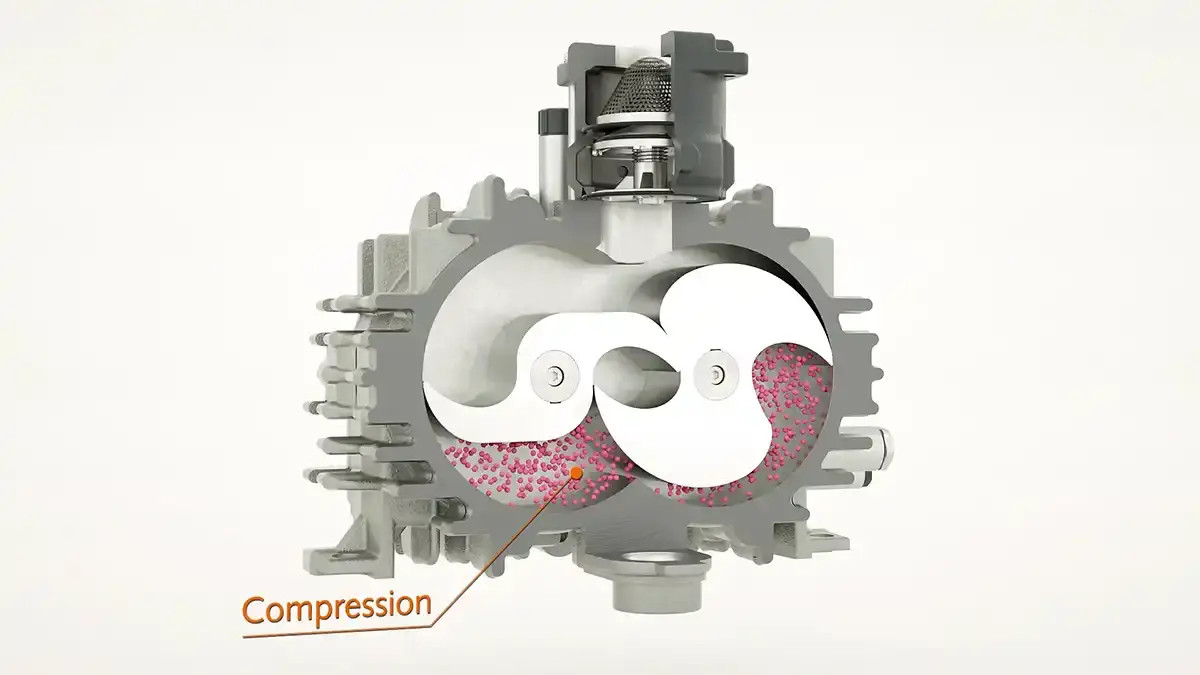

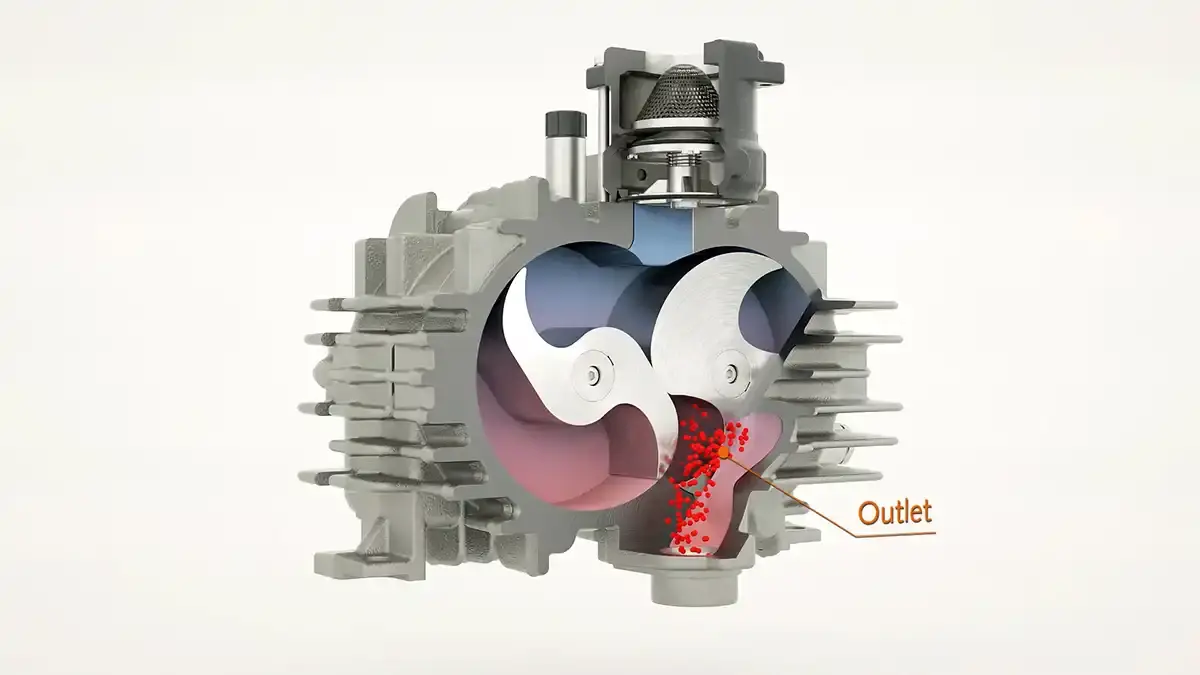

Dry claw vacuum pumps from Busch operate within the rough vacuum range. Therefore, they are perfectly suited for industrial applications in which constant vacuum and oil-free operation are essential.Claw compressors operate according to the same principle.

Product series | Nominal pumping speed | Function |

|---|---|---|

MINK MA/MB | 18 m³/h | vacuum pump / compressor |

MINK MI | 50 m³/h – 580 m³/h | vacuum pump / compressor |

MINK MV | 40 m³/h – 1,200 m³/h | vacuum pump |

MINK MM | 62 m³/h – 600 m³/h | vacuum pump |

MINK MM | 62 m³/h – 330 m³/h | compressor |

MINK MH | 18 m³/h | compressor |