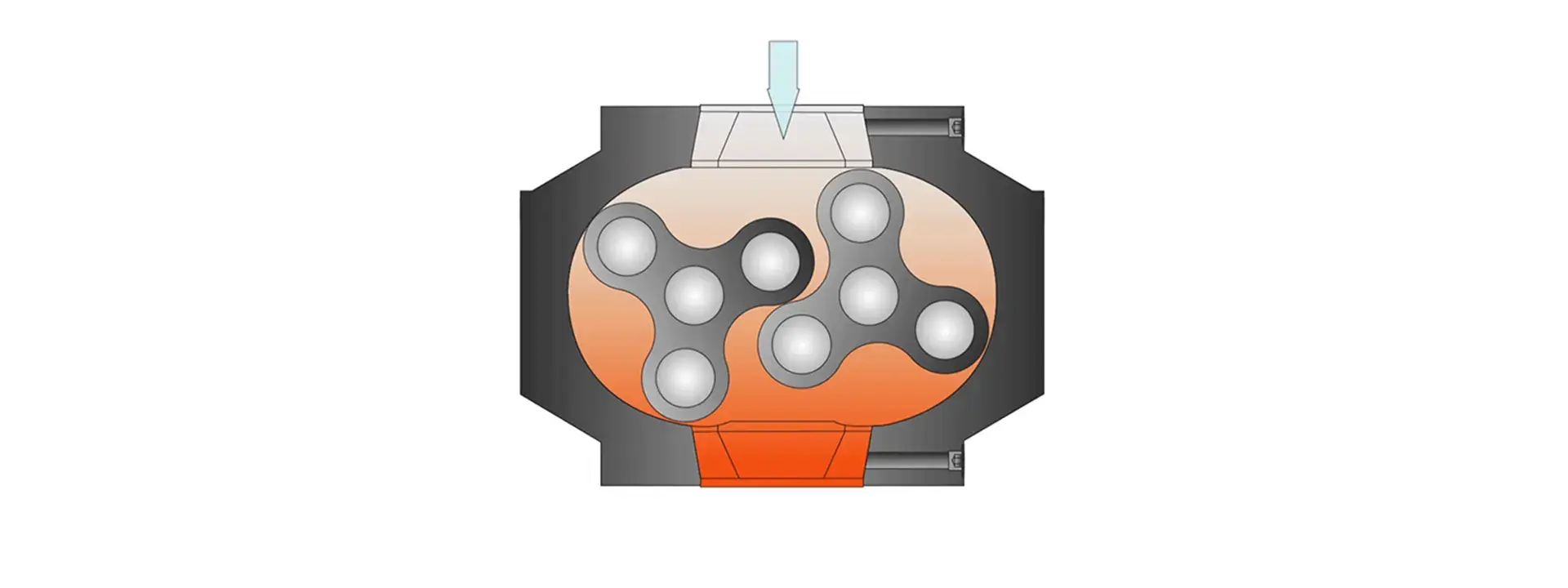

Types of rotary lobe blowers

The robust construction and high manufacturing quality of rotary lobe blowers from Busch ensure outstanding reliability and durability.Due to their dry operating principle, there is no need for oil or other lubricants.

Product family | Nominal pumping speed |

|---|---|

TYR | 850-4700 min-1 |