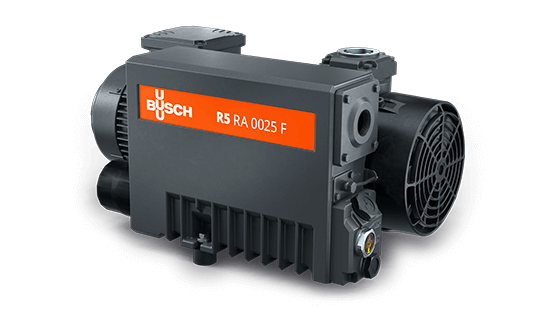

The All-Rounder for Countless Vacuum Applications

Reliable

Robust construction, highly durable fiber-reinforced epoxy resin vanes, proven rotary vane technology, long service life

High performance

High pumping speed at low pressures, designed for continuous operation

Flexible

Various design options available, easy adaption to individual customer requirements and processes

Technical specifications

Markets & applications

Automotive and Transport

-

Vacuum Cleaning / Parts to clean

-

Leak Detection and EoL Testing

-

Vacuum Sewage

-

Fluid Evacuation and Charging

Battery

-

Degassing

-

Mixing

-

Impregnating

-

Leak Detection and EoL Testing (Master)

-

Recycling

-

Vacuum drying

-

Electrolyte filling

Carbon Capture

-

Membrane Capture

-

Amine Scrubbing

-

Pressure Swing Adsorption

-

Moving Bed Process

Chemical

-

Packaging

-

Filtration, Degassing

-

Distillation, Solvent Recovery

-

Evaporation, Drying

Confectionary

-

Wrapping and packaging

-

Vacuum extrusion

Dairy

-

Milking

-

Cheese production - vacuum packaging

Food Processing

-

Powder processing

-

Meat fillers

-

Meat cutters

Hydrogen Economy

-

Hydrogen Storage and Distribution

-

Leak Detection and EoL Testing (Master)

Medical

-

Medical Suction

Metallurgy

-

Die Casting

Packaging

-

Chamber machines free standing

-

Molding

-

Liquid packaging

-

Blister packaging

-

Labeling

-

Thermoforming machines forming station

-

Clipping machines

-

Cartoning machines

-

Tray sealers

-

Tray loading systems

Pharmaceutical industry

-

Filtration, Degassing

-

Evaporation, Drying

-

Packaging

-

Distillation, Solvent Recovery

Plastics processing

-

Vacuum Bagging

-

Thermoforming

-

Resin Transport Moulding (RTM)

-

Injection Moulding

Refrigeration and Air Condition

-

Vacuum Evacuation and Filling

-

Leak Detection and EoL Testing

-

Vacuum Drying

Technical Gases

-

Gas Transport

-

Bottle Filling

Wastewater Treatment

-

Vacuum Sewage

Woodworking

-

Clamping on Manual Working Stations

-

Pneumatic Conveying

Accessories

- Gas-ballast valve

- Various inlet filters

- Filter pressure gauge

- Oil level switch

- Vacuum pump oils for all applications

- Vacuum regulating unit

Design options

-

ATEX - for use in explosion hazard areas.

-

Oxygen - for transporting gas mixtures with an oxygen content of over 21%.

-

Aqua - for higher water vapor capacity.