MINK

Compressores e bombas de vácuo de garras secas

Os compressores e as bombas de vácuo de garras MINK são o resultado do desenvolvimento contínuo da tecnologia de garra. Décadas de experiência em inúmeras aplicações nos levaram a melhorias substanciais.

A tecnologia de garra MINK combina desempenho, confiabilidade e eficiência com um design inovador. Ela pode ser utilizada tanto para a geração de vácuo como para a geração de ar comprimido.

O princípio de operação a seco e sem contato tem a vantagem de proporcionar uma operação quase livre de manutenção.

Os compressores e as bombas de vácuo MINK são perfeitamente adequados a aplicações industriais, nas quais o vácuo ou a sobrepressão constantes e a operação sem óleo são essenciais.

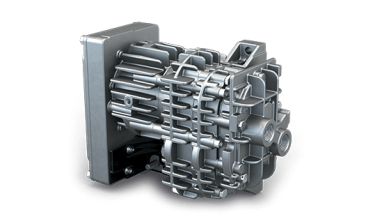

Princípio de operação

Os compressores e as bombas de vácuo de garras MINK possuem dois rotores em forma de garra. Os rotores estão montados em uma estrutura e se movem em direções opostas. A forma desses rotores de garra extrai, comprime e expele o meio bombeado.A folga mínima entre os rotores e a estrutura da câmara otimiza o selo interno. Assim, não são necessários lubrificantes ou fluidos de operação na câmara de compressão.

Os compressores e as bombas de vácuo MINK são acionados por um motor montado diretamente na flange. Uma caixa de velocidades de sincronização garante a precisão do tempo do rotor.

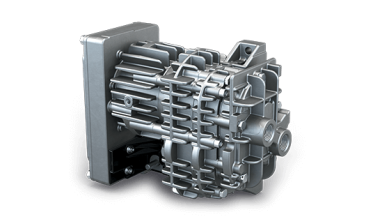

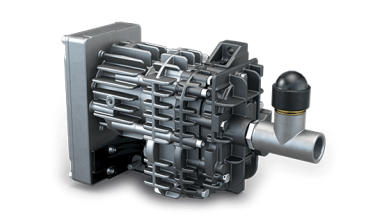

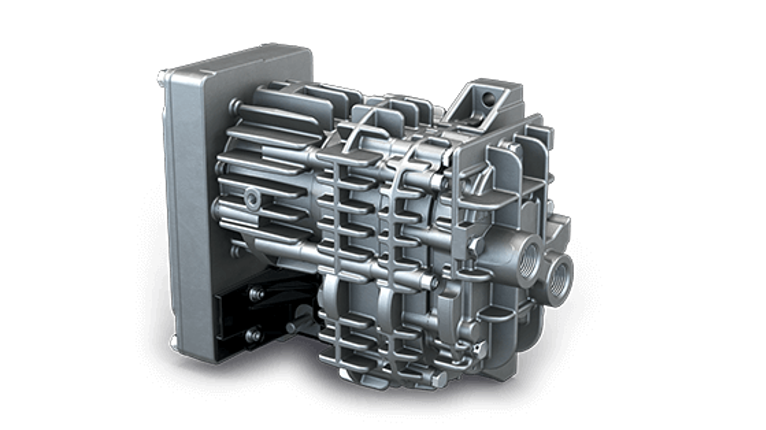

MINK MA

- Concebidas especialmente para aplicações móveis

- Design compacto

- Resistentes a vibrações

- Operação sob condições extremas

- Compressão sem contato e a seco

- Sem manutenção

- Controle de velocidade integrado

Vantagens da série MINK MA

MINK MA são compressores de garra seca especialmente desenvolvidos para comprimir ou transportar ar em aplicações móveis, principalmente para o setor automotivo e de transportes.

Esses compressores são resistentes a fortes vibrações. Eles podem ser operados em faixas de temperatura entre -40 °C e +100 °C e a elevações entre -1.000 m e 4.000 m.

O design "all-in-one" resulta em um formato muito compacto, fazendo da MINK MA a solução ideal para aplicações móveis.

O princípio de operação é seco. Desse modo, o meio bombeado não é contaminado e pode ser utilizado posteriormente sem necessidade de filtragem ou limpeza.

Nenhuma das peças móveis internas entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são eliminadas por completo.

Um controle de velocidade integrado permite que o volume de vazão seja alterado de forma dinâmica. Assim, os compressores MINK MA operam sempre dentro da faixa de desempenho mais eficiente.

O sistema de comunicação CAN permite que parâmetros, como a velocidade de rotação, o consumo de energia e a temperatura, sejam permanentemente registrados e controlados.

Todos os produtos MINK MA

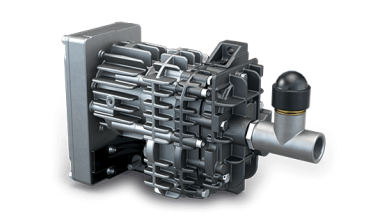

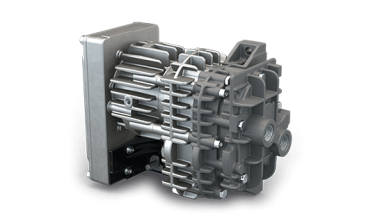

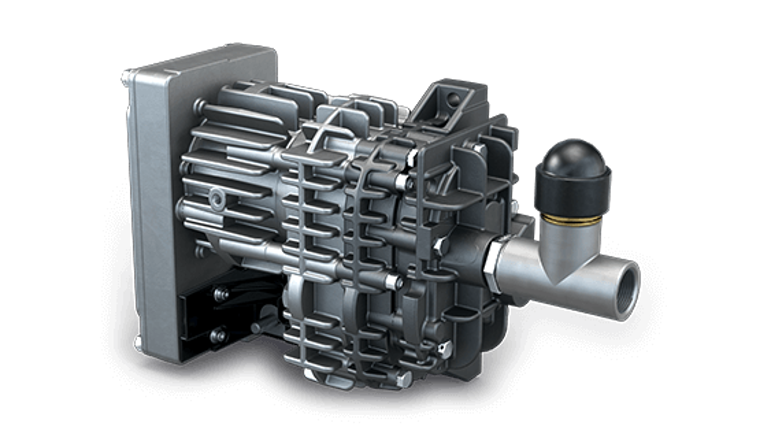

MINK MB

- Concebidas especialmente para aplicações móveis

- Design compacto

- Resistentes a vibrações

- Operação sob condições extremas

- Compressão sem contato e a seco

- Sem manutenção

- Controle de velocidade integrado

Vantagens da série MINK MB

MINK MB são bombas de vácuo de garras secas destinadas principalmente ao setor automotivo e de transporte.

Elas são resistentes a fortes vibrações e podem ser operadas em faixas de temperatura entre -40 °C e +40 °C.

O design "all-in-one" resulta em um formato muito compacto, o que faz da MINK MB a solução ideal para aplicações móveis.

O princípio de operação é seco. Desse modo, o meio bombeado não é contaminado e pode ser utilizado posteriormente sem necessidade de filtragem ou limpeza.

Nenhuma das peças móveis internas entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são eliminadas por completo.

Um controle de velocidade integrado permite que a velocidade de bombeamento seja alterada de forma dinâmica. Assim, as bombas de vácuo MINK MB operam sempre dentro da faixa de desempenho mais eficiente.

O sistema de comunicação CAN permite que parâmetros, como a velocidade de rotação, o consumo de energia e a temperatura, sejam permanentemente registrados e controlados.

Todos os produtos MINK MB

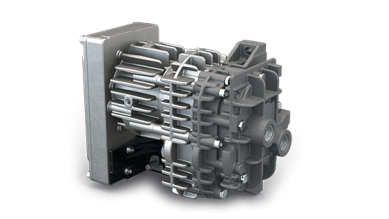

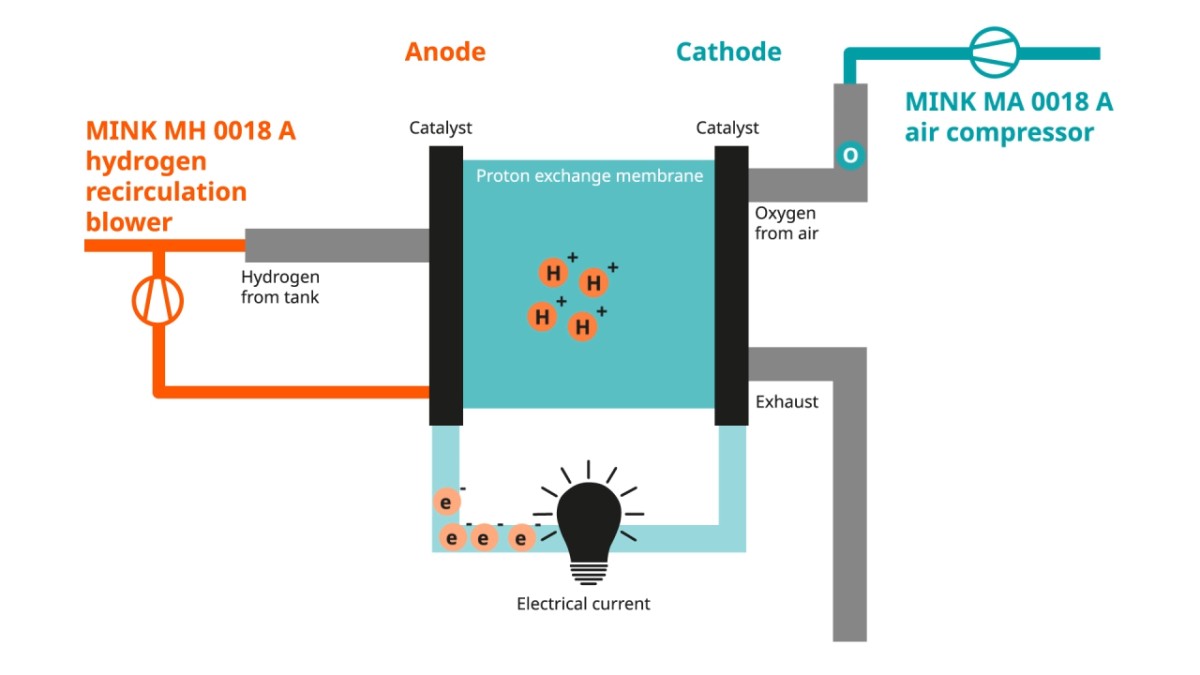

MINK MH

- Concebidos especialmente para células de combustível

- Aprovados para hidrogênio pelo SGS-TÜV

- Design compacto

- Resistentes a vibrações

- Operação sob condições extremas de temperatura

- Princípio de operação a seco e sem contato

- Sem manutenção

- Controle de velocidade integrado

Vantagens da série MINK MH

MINK MH são compressores de garra aprovados para hidrogênio, especialmente desenvolvidos para a recirculação de hidrogênio (H2em células de combustível.

Eles são resistentes a níveis de vibração fortes e podem ser operados sob condições extremas de temperatura entre -30°C e +85°C.

O design "all-in-one" resulta em um formato muito compacto, fazendo do MINK MH a solução ideal para todas as células de combustível.

A sua compressão é seca. Isso significa que não existem fluidos de operação na câmara de compressão.

Nenhuma das peças móveis internas do compressor entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são eliminadas por completo.

Um controle de velocidade integrado permite que o volume de vazão seja alterado de forma dinâmica. Assim, o MINK MH opera sempre dentro da faixa de desempenho mais eficiente. O seu volume de vazão permanece constante durante todo o ciclo de vida.

O sistema de comunicação CAN permite que parâmetros, como a velocidade de rotação e o consumo de energia, sejam permanentemente registrados e controlados.

Campos de aplicação

Os compressores Mink MH são a solução ideal para os seguintes setores, nos quais a recirculação de hidrogênio desempenha um papel importante:

- Transporte: automotivo, ferroviário, marítimo, aviação

- Estacionário: geração de eletricidade

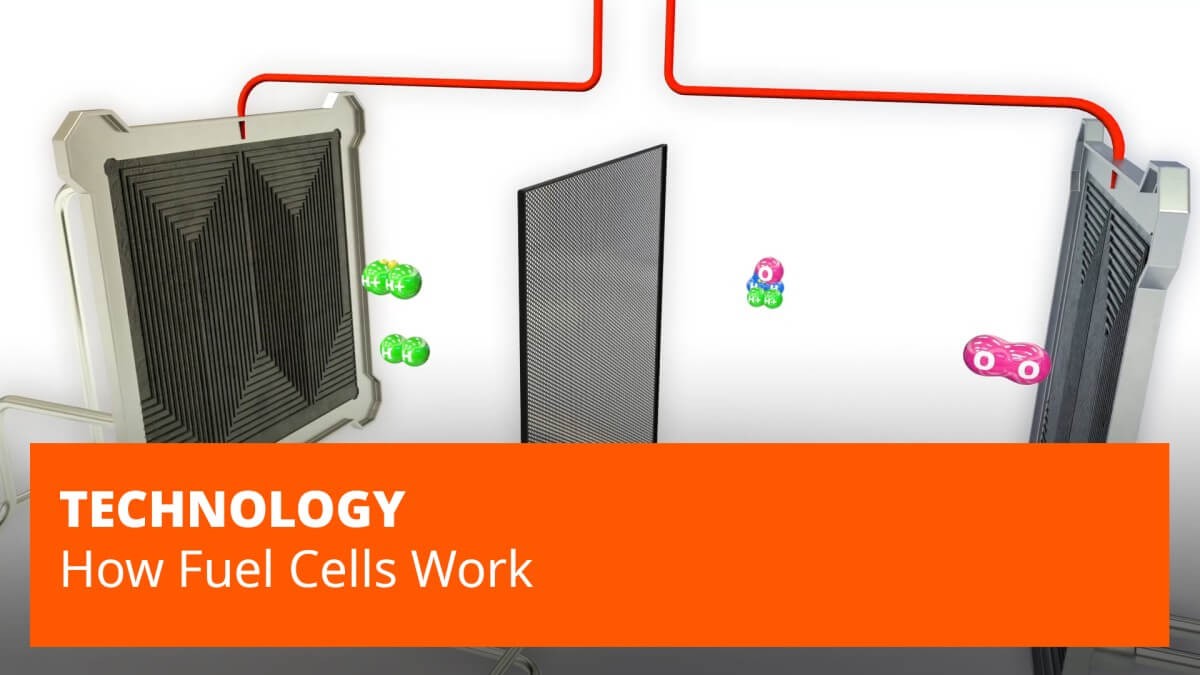

Princípio de operação da célula de combustível

Em uma célula de combustível, uma combinação de hidrogênio (vindo do tanque) e oxigênio (do ar) produz eletricidade, calor e água como subproduto.

Uma célula de combustível consiste em dois eletrodos, um ânodo e um cátodo. Eles são separados por uma membrana, que é responsável pelo transporte de íons.

O hidrogênio é alimentado do lado do ânodo e o oxigênio do lado do cátodo. As moléculas de hidrogênio são divididas em prótons e elétrons.

Os prótons do hidrogênio se difundem através da membrana até o cátodo, onde reagem com o oxigênio para formar água, liberando energia.

É importante que o oxigênio não se difunda no circuito de hidrogênio para evitar condições explosivas. Portanto, o hidrogênio é injetado em quantidade maior. Devido aos regulamentos legais e por motivos de eficiência, este excesso de hidrogênio não deve ser liberado para a atmosfera.

A solução é recircular este hidrogênio de volta para a entrada do sistema. Para isso, nosso compressor de garra MINK MH entra em operação. Ele foi especialmente desenvolvido para a recirculação do excesso de hidrogênio em células de combustível e é aprovado para hidrogênio pela TÜV Saar.

Todos os produtos MINK MH

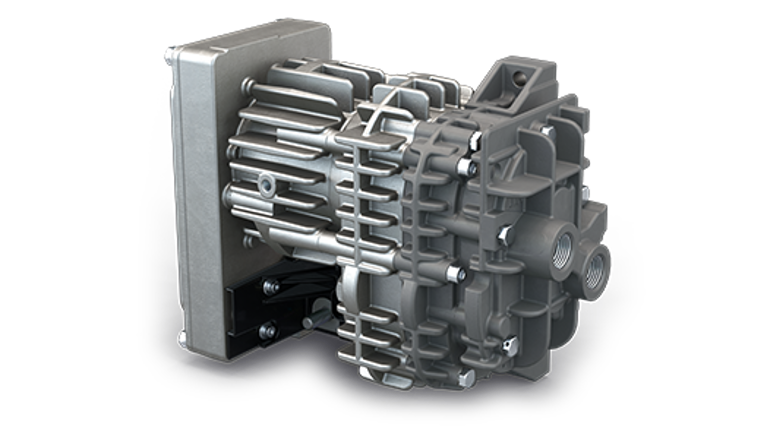

Bombas de vácuo MINK MI/MM

- Geração de vácuo industrial confiável

- Níveis altamente eficientes

- Quase livres de manutenção

- Compressão sem contato e a seco

Vantagens da série de bombas de vácuo MINK MI/MM

As bombas de vácuo de garras MINK MI/MM foram especialmente concebidas para a geração de vácuo industrial confiável, por exemplo, para transporte pneumático, termoformagem, processamento de plástico, marcenaria e muito mais.

Essas bombas de vácuo operam a níveis altamente eficientes. Elas fornecem velocidades de bombeamento constantemente altas durante todo o ciclo de vida e com consumo de energia significativamente mais baixo do que os geradores de vácuo convencionais da mesma classe de desempenho.

O princípio de operação sem contato tem a vantagem da operação quase livre de manutenção. Nenhuma das peças móveis internas entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são reduzidas ao mínimo.

A tecnologia comprovada de vácuo de garras secas permite que a MINK MI/MM funcione sem fluidos de operação na câmara de compressão. Na prática, isso significa que não há contaminação do meio bombeado e emissão para o ambiente.

Todas as bombas de vácuo MINK MI/MM

Compressores MINK MI/MM

- Geração de ar comprimido confiável

- Níveis altamente eficientes

- Quase livres de manutenção

- Compressão sem contato e a seco

Vantagens da série de compressores MINK MI/MM

Os compressores de garra MINK MI/MM foram especialmente concebidos para a geração de sobrepressão industrial confiável, por exemplo, para transporte pneumático, desgaseificação de água, tratamento de água, aplicações de piscicultura e muito mais.

Esses compressores operam a níveis altamente eficientes. Eles fornecem volumes de vazão constantemente altos durante todo o seu ciclo de vida com consumo de energia significativamente mais baixo do que os compressores convencionais da mesma classe de desempenho.

O princípio de operação sem contato tem a vantagem da operação quase livre de manutenção. Nenhuma das peças móveis internas entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são reduzidas ao mínimo.

A tecnologia comprovada de garras secas permite que o MINK MI/MM funcione sem fluidos de operação na câmara de compressão. Na prática, isso significa que não há contaminação do meio bombeado e emissão para o ambiente.

Todos os compressores MINK MI/MM

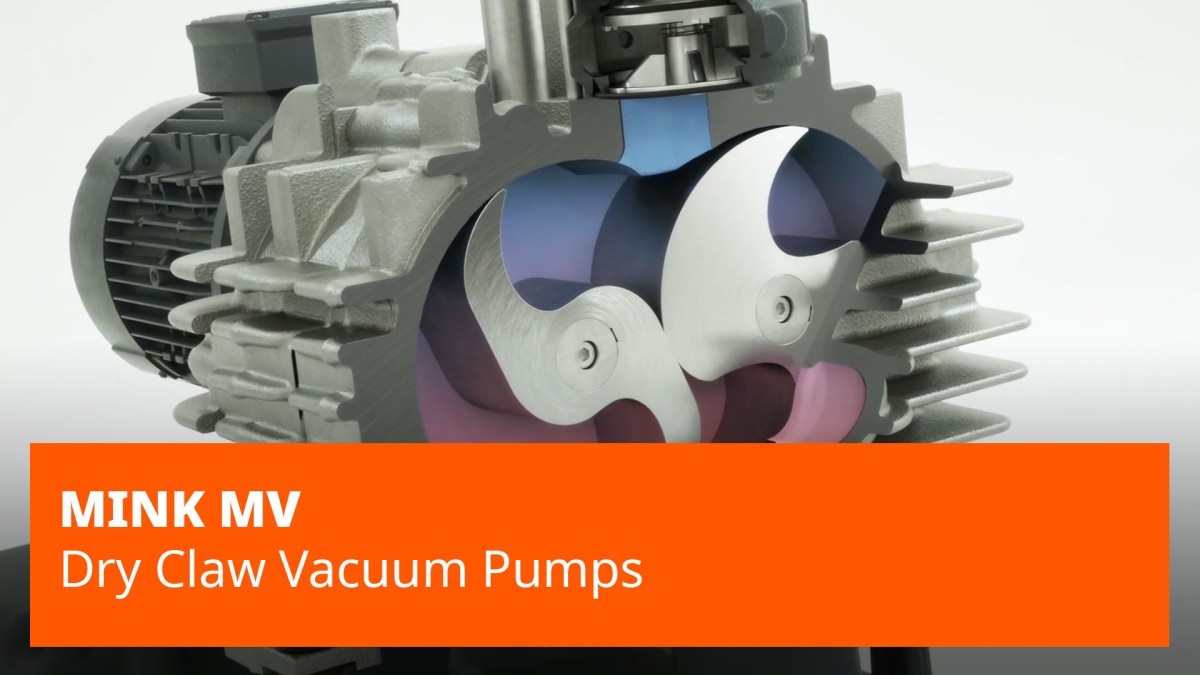

MINK MV

- Mais recente tecnologia de vácuo de garras

- Design acústico de última geração

- Redução geral de até 50% nos custos operacionais

- Formato compacto

- Quase livres de manutenção

- Compressão sem contato e a seco

Vídeo: Funcionamento das bombas de vácuo MINK MV

Vantagens da série MINK MV

MINK MV é o novo padrão de bombas de vácuo de garras.

Elas são três vezes melhores que os geradores de vácuo convencionais semelhantes: mais silenciosas, mais eficientes, mais compactas.

Essas bombas de vácuo foram especialmente concebidas para um grande número de aplicações, por exemplo, marcenaria, transporte pneumático ou processamento de plástico.

O isolamento acústico otimizado é produzido de acordo com os mais recentes desenvolvimentos em termos de design acústico. Desse modo, os baixos níveis de ruído permitem uma operação silenciosa próximo de estações de trabalho.

Graças ao seu design sofisticado, as bombas de vácuo MINK MV atingem níveis excepcionais de alta eficiência. Elas podem reduzir os custos operacionais gerais em até 50% em comparação com os geradores de vácuo convencionais.

Com as suas dimensões compactas, as bombas de vácuo MINK MV podem ser instaladas nos espaços mais reduzidos.

O princípio de operação sem contato tem a vantagem de proporcionar uma operação quase livre de manutenção. Nenhuma das peças móveis internas entra em contato com a outra. Os componentes não estão sujeitos a desgaste e as tarefas de manutenção são reduzidas ao mínimo.

A tecnologia comprovada de vácuo de garras secas permite que a MINK MV funcione sem fluidos de operação na câmara de compressão. Na prática, isso significa que não há contaminação do meio bombeado e emissão para o ambiente.

Todos os produtos MINK MV

MINK MW

- Mais recente tecnologia de vácuo de garras

- Baixo consumo de energia

- Quase livres de manutenção

- Compressão sem contato e a seco

Vantagens da série MINK MW

A MINK MW é a primeira série de bomba de vácuo de garras que pode ser operada continuamente a uma pressão final de 0,8 hPa (mbar). As aplicações preferidas para a MW incluem termoformagem, pegar e colocar, fundição a vácuo, sistema central de vácuo para embalagem e resfriamento a vácuo.

Essas bombas de vácuo operam a níveis altamente eficientes. Elas oferecem velocidades de bombeamento consistentemente altas ao longo de todo o seu ciclo de vida, com um consumo de energia significativamente menor em comparação aos geradores de vácuo convencionais da mesma potência.

O princípio de operação sem contato tem a vantagem da operação quase livre de manutenção. Nenhuma das peças móveis internas entra em contato uma com a outra, portanto, os componentes não estão sujeitos a desgaste e as tarefas de serviço são minimizadas.

A tecnologia comprovada de vácuo de garras secas permite que a MINK MW funcione sem fluidos de operação na câmara de compressão. Na prática, isso significa que não há contaminação do meio bombeado e emissão para o ambiente.