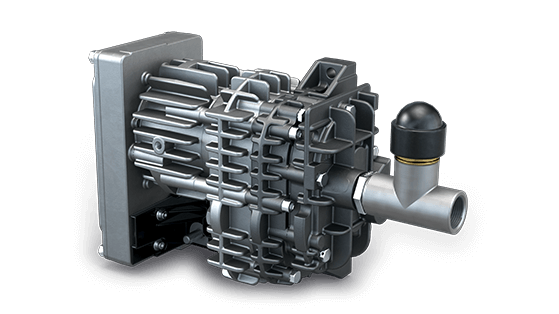

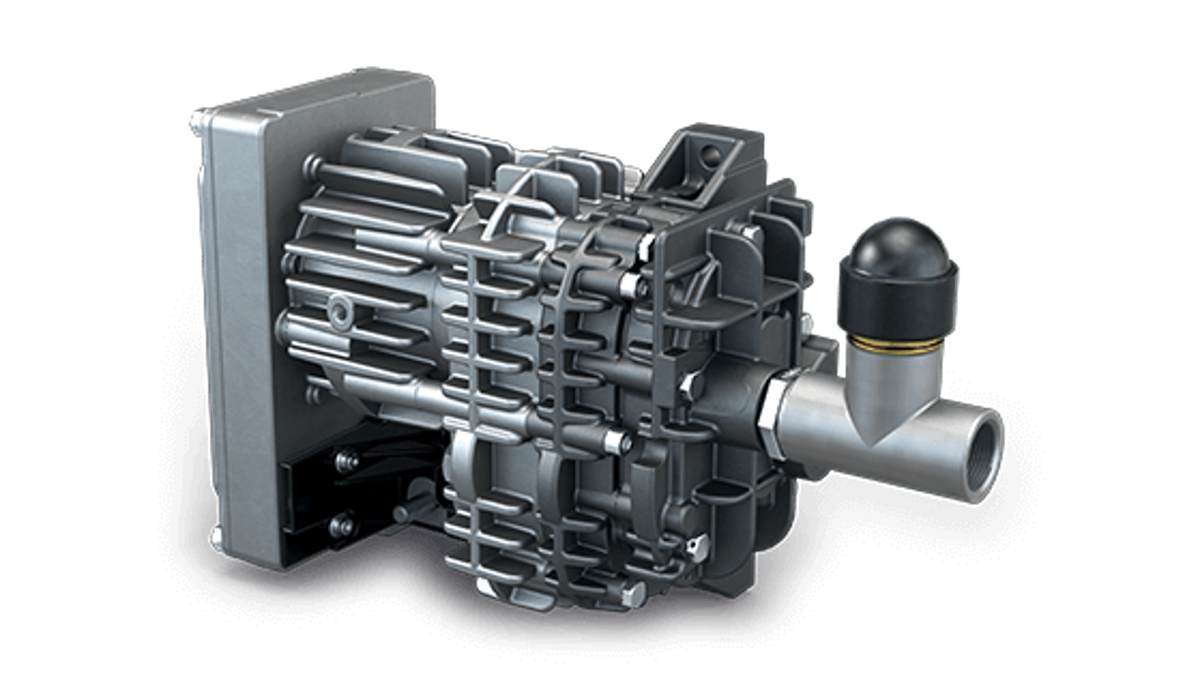

Vácuo para aplicações móveis sujeitas a condições extremas

Robusta

Especialmente concebida para aplicações móveis, ela pode ser operada sob condições extremas, em faixas de temperatura entre -40 °C e +40 °C e a altitudes entre -1.000 m e 4.000 m, resistente a fortes vibrações

Eficiente

A mais recente tecnologia de vácuo de garras, compressão sem contato e a seco, sem contaminação do meio bombeado, acionamento da velocidade inteligente e variável, baixo consumo de energia, ciclo de vida longo sem manutenção

Compactos

Impacto reduzido devido ao design "all-in-one"

Especificações técnicas

Mercados e aplicações

Economia de hidrogênio

-

Recirculação de hidrogênio