Intelligent use of vacuum for food packaging

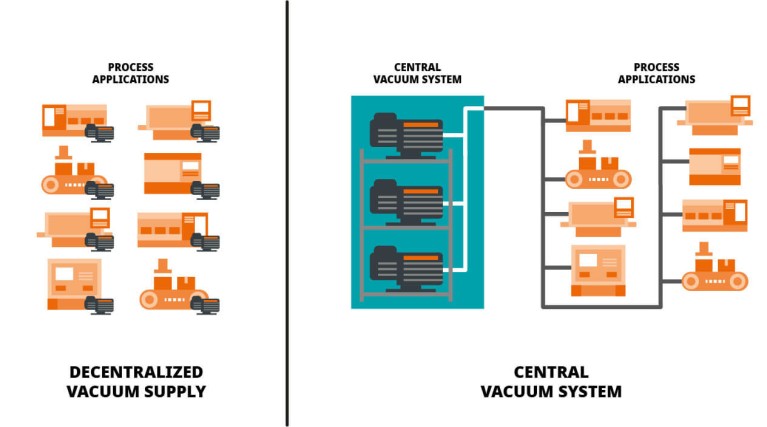

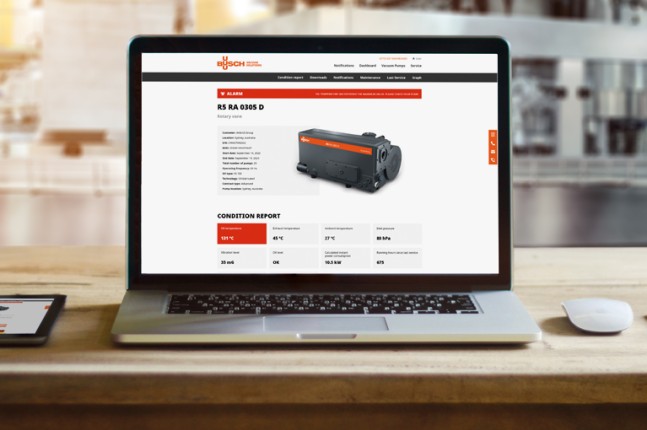

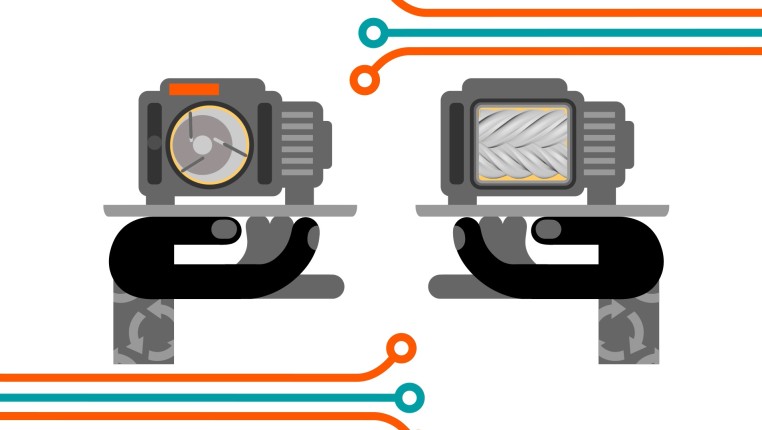

Feinkost Dittmann, a German delicatessen manufacturer, has installed a Busch vacuum system for its packaging machines.Half the vacuum pumps supply the base load in permanent operation at their optimum point of efficiency. The other vacuum pumps are frequency-controlled to respond to demand fluctuations.

Busch Vacuum Control ensures fine tuning of the pumping speed to match current demand. Energy consumption has been reduced by more than 70% compared to simple on/off operation mode.