At Jud Bio-Jungpflanzen, field vegetable seedlings are grown for the Swiss market. Photo: Busch Vacuum Solutions.

Sowing with the Help of Vacuum: Precise, Reliable and Fast

Jud Bio-Jungpflanzen AG

500 boxes of seedlings per hour instead of the previous 300 are being stocked by the Swiss organic nursery Jud Bio-Jungpflanzen (young plants) AG. This is thanks to a new seeder that uses a vacuum pump from Busch Vacuum Solutions.

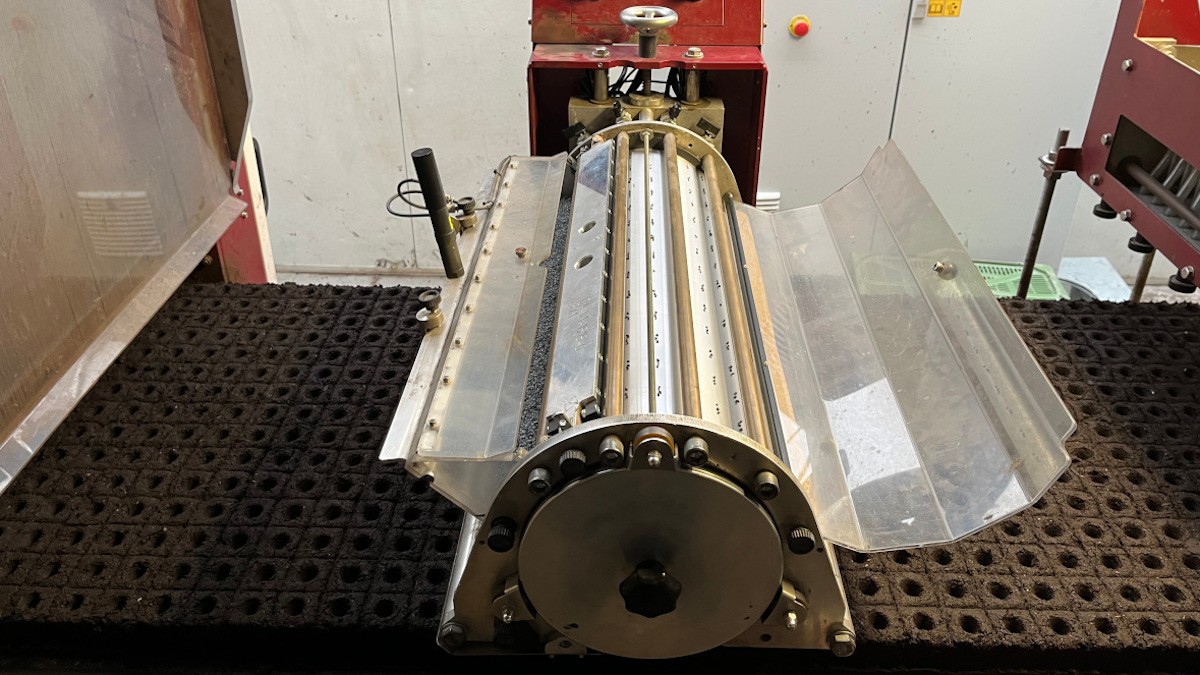

With each rotation of the seed drum, a precisely defined number of seeds fall into pre-cut hollows in cubes of soil, known as earth press pots. The machine at work here is called a soil blocking machine. Piece by piece, the soil cubes move further forward on a conveyor belt, the drum rotates continuously, and the next seeds fall into the prepared earth.

Automated seeding process

This process is made possible by vacuum. The seed drum has tiny holes, with spacing that exactly matches the hollows of the soil press pots. This makes sure that the seeds are optimally deposited. A dry MINK MM claw vacuum pump from Busch Vacuum Solutions evacuates the air from inside the hollow seed drum, causing seeds to adhere to the holes on the outside. These are then scraped off by a metal sheet above the soil press pots. Depending on the type of plant, different seed drums are available. Each is perforated differently and can be replaced as needed.

An employee uses an easy-to-operate touchscreen to set the vacuum required for each type of plant separately. This is important to ensure that the desired number of seeds is placed in each soil press pot. This in turn enables uniform growth of the plants for their later sale.

Automated seeding process

This process is made possible by vacuum. The seed drum has tiny holes, with spacing that exactly matches the hollows of the soil press pots. This makes sure that the seeds are optimally deposited. A dry MINK MM claw vacuum pump from Busch Vacuum Solutions evacuates the air from inside the hollow seed drum, causing seeds to adhere to the holes on the outside. These are then scraped off by a metal sheet above the soil press pots. Depending on the type of plant, different seed drums are available. Each is perforated differently and can be replaced as needed.

An employee uses an easy-to-operate touchscreen to set the vacuum required for each type of plant separately. This is important to ensure that the desired number of seeds is placed in each soil press pot. This in turn enables uniform growth of the plants for their later sale.

-

View of the seed drum. Photo: Busch Vacuum Solutions.

Once a box filled with soil cubes has been loaded with seeds, it is automatically sprinkled with sand to protect the seeds from drying out. The boxes are stacked and finally moved to a special germination room. Once the seeds have germinated, the pallets are laid out in the greenhouses, where the seedlings are grown.

-

The boxes containing the soil press pots are sprinkled with sand and taken to a special germination room. Photo: Busch Vacuum Solutions.

Young organic plants since 1990

Beat Jud founded his company in 1990, and it has been a joint stock company since 2016. Today, with a team of 21 employees, he cultivates young vegetable plants, herbs and strawberry plants in a greenhouse area totaling 29,000 m². He has 40 different vegetable and herb varieties in his assortment. Depending on demand, the company offers seedlings in various pot sizes or on cultivation plates and sells them to vegetable producers and nurseries throughout Switzerland. These grow the plants and then deliver them to retailers or distribute the organic products themselves at markets around the country. The family business, which is certified by Bio-Suisse, has two locations in the Swiss canton of Thurgau, in Tägerwilen on Lake Constance and 15 kilometers away in Bonau.

Seeders have been in use at Jud Bio-Jungpflanzen since 1995. The first one could load up to 300 boxes per hour with seeds. In 2009, the company purchased the first soil blocking machine with an automatic box stacker. This new development worked with a vacuum pump from Busch and could manage 400 to 500 crates per hour. Another advantage of the soil blocking machine is that it requires less supervision than the company’s first seeder. “With the old machine, several of my employees had to monitor it to ensure that the seeds were placed properly in the soil press pots. On the modern soil blocking machine, there are only two employees at work. One checks, and the other takes care of the pallets. Vacuum makes it possible,” says Jud.

Vacuum makes it possible

Company founder Beat Jud was so satisfied with the vacuum-assisted solution that he bought the latest model of the soil blocking machine in 2019, again with the latest MINK from Busch. Now his team fills 500 crates per hour. “The new system is extremely fast and extremely reliable. I am more than satisfied that we have been able to increase our production to such an extent with the help of the system. This has enabled us to continue to meet growing demand. Maintenance of the vacuum pump is also very simple. We only have to check the oil and change the filters from time to time,” says the delighted entrepreneur.

Jud is impressed with the good contact with the vacuum specialists at Busch, who are always immediately available and quickly on site thanks to a nearby service branch. This is why he has now also signed a service contract with Busch: “If the vacuum pump isn’t running, I can’t work. If it fails once, it has to run again within four to five hours. Otherwise, we have a real problem. That’s why it’s great that Busch offers such fast service.”

Beat Jud founded his company in 1990, and it has been a joint stock company since 2016. Today, with a team of 21 employees, he cultivates young vegetable plants, herbs and strawberry plants in a greenhouse area totaling 29,000 m². He has 40 different vegetable and herb varieties in his assortment. Depending on demand, the company offers seedlings in various pot sizes or on cultivation plates and sells them to vegetable producers and nurseries throughout Switzerland. These grow the plants and then deliver them to retailers or distribute the organic products themselves at markets around the country. The family business, which is certified by Bio-Suisse, has two locations in the Swiss canton of Thurgau, in Tägerwilen on Lake Constance and 15 kilometers away in Bonau.

Seeders have been in use at Jud Bio-Jungpflanzen since 1995. The first one could load up to 300 boxes per hour with seeds. In 2009, the company purchased the first soil blocking machine with an automatic box stacker. This new development worked with a vacuum pump from Busch and could manage 400 to 500 crates per hour. Another advantage of the soil blocking machine is that it requires less supervision than the company’s first seeder. “With the old machine, several of my employees had to monitor it to ensure that the seeds were placed properly in the soil press pots. On the modern soil blocking machine, there are only two employees at work. One checks, and the other takes care of the pallets. Vacuum makes it possible,” says Jud.

Vacuum makes it possible

Company founder Beat Jud was so satisfied with the vacuum-assisted solution that he bought the latest model of the soil blocking machine in 2019, again with the latest MINK from Busch. Now his team fills 500 crates per hour. “The new system is extremely fast and extremely reliable. I am more than satisfied that we have been able to increase our production to such an extent with the help of the system. This has enabled us to continue to meet growing demand. Maintenance of the vacuum pump is also very simple. We only have to check the oil and change the filters from time to time,” says the delighted entrepreneur.

Jud is impressed with the good contact with the vacuum specialists at Busch, who are always immediately available and quickly on site thanks to a nearby service branch. This is why he has now also signed a service contract with Busch: “If the vacuum pump isn’t running, I can’t work. If it fails once, it has to run again within four to five hours. Otherwise, we have a real problem. That’s why it’s great that Busch offers such fast service.”