Source: Busch Vacuum Solutions.

5 Reasons Why Not to Skip Vacuum Pump Maintenance

No one thinks fondly of their last visit to the dentist. No one counts down the days to their next appointment, eagerly waiting to see what news their dentist breaks to them while rubber-gloved fingers probe uncomfortably in their mouth. But we know that not visiting the dentist comes with consequences. Consequences that are far more painful, more time-consuming, and above all, more costly than just getting it over with. Vacuum pump maintenance is the same.

It can be very easy to let service intervals get a little too long. After all, servicing inevitably means a certain amount of downtime, and downtime means loss of revenue. But pump failure means downtime that you can’t plan for – and some breakdowns can leave your vacuum pump irreparable. Discover what can happen to your vacuum pump if you fail to carry out routine maintenance in a timely manner.

-

Source: Busch Vacuum Solutions.

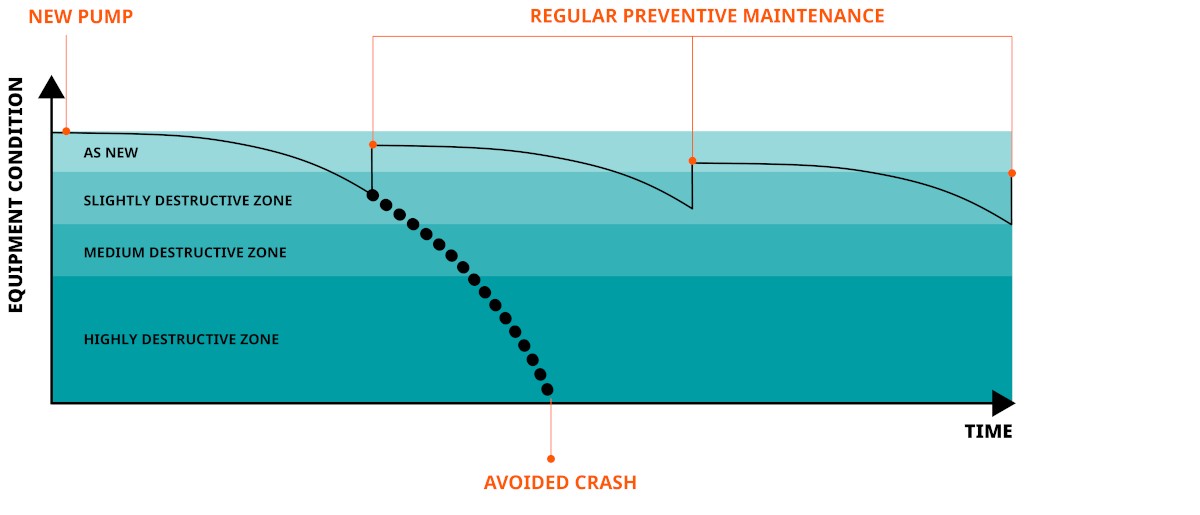

1. Shorter pump lifetime

Failing to carry out regular preventive maintenance inevitably leads to a complete breakdown sooner or later. While your vacuum pump can recover from some types of breakdowns – once costly repairs or remanufacturing have been carried out – others mean goodbye.

A vacuum pump that is treated well will last longer. Depending on the type of vacuum pump, a lifetime of 30 years or more is possible! A minor maintenance issue – like an oil change, or replacing a worn vane or seal – is a relatively low investment, both in terms of time and cost. And it is vital to ensuring the longevity of your vacuum pump.

Failing to carry out regular preventive maintenance inevitably leads to a complete breakdown sooner or later. While your vacuum pump can recover from some types of breakdowns – once costly repairs or remanufacturing have been carried out – others mean goodbye.

A vacuum pump that is treated well will last longer. Depending on the type of vacuum pump, a lifetime of 30 years or more is possible! A minor maintenance issue – like an oil change, or replacing a worn vane or seal – is a relatively low investment, both in terms of time and cost. And it is vital to ensuring the longevity of your vacuum pump.

-

Source: Busch Vacuum Solutions.

2. Lower efficiency

As the service interval increases and parts wear out, energy consumption climbs. Take an exhaust filter, for example. A filter that is ready to be changed is already saturated with oil. Pushing the exhaust air through it is therefore more difficult for the vacuum pump, causing it to draw more power. When the old filter is exchanged for a new one, the vacuum pump does not have to work as hard to expel the gas. This means a lower carbon footprint and a happier vacuum pump.

As the service interval increases and parts wear out, energy consumption climbs. Take an exhaust filter, for example. A filter that is ready to be changed is already saturated with oil. Pushing the exhaust air through it is therefore more difficult for the vacuum pump, causing it to draw more power. When the old filter is exchanged for a new one, the vacuum pump does not have to work as hard to expel the gas. This means a lower carbon footprint and a happier vacuum pump.

-

Source: Busch Vacuum Solutions.

3. Higher costs

Compare the cost of an oil change with the cost of repairing a vacuum pump that has failed because of insufficient lubrication. Or the cost of regular maintenance with the price of replacing the rotor, cylinder and cylinder cover in a rotary vane vacuum pump because of a broken vane. Also, as we saw above, not replacing spare parts regularly leads to lower energy efficiency – and a high electricity bill.

Here, you should consider not only the cost of what needs to be changed, but also the cost of the time lost in production as a result of a breakdown. It is therefore a much more sensible idea to carry out the comparatively cheap routine maintenance rather than risk having to shell out for replacement parts.

Compare the cost of an oil change with the cost of repairing a vacuum pump that has failed because of insufficient lubrication. Or the cost of regular maintenance with the price of replacing the rotor, cylinder and cylinder cover in a rotary vane vacuum pump because of a broken vane. Also, as we saw above, not replacing spare parts regularly leads to lower energy efficiency – and a high electricity bill.

Here, you should consider not only the cost of what needs to be changed, but also the cost of the time lost in production as a result of a breakdown. It is therefore a much more sensible idea to carry out the comparatively cheap routine maintenance rather than risk having to shell out for replacement parts.

-

Source: Busch Vacuum Solutions

4. More noise and vibration

A production room is a noisy place. A poorly maintained vacuum pump will make it even louder. Extra noise on the production floor is an annoyance to your employees. And, if it continues over an extended period, it can be a health hazard.

A rattling could indicate that there are small particles of dust in the compression chamber. A rotary vane vacuum pump may make a chattering noise when its vanes are worn down and need replacement. And extra vibration can be the result of worn bearings. The longer the problem persists, the more damage it can do – and the noisier it will get. Better to get it checked promptly and restore the peace.

A production room is a noisy place. A poorly maintained vacuum pump will make it even louder. Extra noise on the production floor is an annoyance to your employees. And, if it continues over an extended period, it can be a health hazard.

A rattling could indicate that there are small particles of dust in the compression chamber. A rotary vane vacuum pump may make a chattering noise when its vanes are worn down and need replacement. And extra vibration can be the result of worn bearings. The longer the problem persists, the more damage it can do – and the noisier it will get. Better to get it checked promptly and restore the peace.

-

Source: Busch Vacuum Solutions.

5. Unplannable timings and higher downtime

If you delay the next service appointment, your vacuum pumps may decide for themselves that it’s time for servicing, and simply break down. This is something you can’t plan for and can lead to lengthy periods of downtime as you wait for service technicians, diagnose issues, wait for spare parts to become available, and fix what now may have become a much larger problem. Planning your maintenance means that you decide when your vacuum pumps go offline. The result: Your process can experience minimal – or even zero – downtime.

If you delay the next service appointment, your vacuum pumps may decide for themselves that it’s time for servicing, and simply break down. This is something you can’t plan for and can lead to lengthy periods of downtime as you wait for service technicians, diagnose issues, wait for spare parts to become available, and fix what now may have become a much larger problem. Planning your maintenance means that you decide when your vacuum pumps go offline. The result: Your process can experience minimal – or even zero – downtime.

How to tell when it’s time for maintenance

When you think that it is time to perform routine maintenance on your vacuum pump, the first step is to conduct a visual pump inspection.

Check the oil

Check the oil level through the sight glass. If it is lower than the allowed limits, it should be topped up. You should also check its condition. As the oil collects contaminants, it becomes darker. Clean oil is nearly opaque and is similar in appearance to vegetable oil. Dark brown or black oil indicates contamination and means you should do an oil change as soon as possible. Your instruction manual will also indicate the recommended oil-change interval.

Check the oil level through the sight glass. If it is lower than the allowed limits, it should be topped up. You should also check its condition. As the oil collects contaminants, it becomes darker. Clean oil is nearly opaque and is similar in appearance to vegetable oil. Dark brown or black oil indicates contamination and means you should do an oil change as soon as possible. Your instruction manual will also indicate the recommended oil-change interval.

Check the filters

Take a look at the different filters on your vacuum pump. This will depend on the pump technology, but could be inlet, outlet, and oil mist separator. As they approach the end of their useful life, they become darker. The darker the filter, the sooner they should be changed.

When you change the oil, you should change the filters at the same time. This avoids previously collected debris making its way into the new oil.

Take a look at the different filters on your vacuum pump. This will depend on the pump technology, but could be inlet, outlet, and oil mist separator. As they approach the end of their useful life, they become darker. The darker the filter, the sooner they should be changed.

When you change the oil, you should change the filters at the same time. This avoids previously collected debris making its way into the new oil.

Look for leaks

In an oil-lubricated vacuum pump, a very small quantity of oil may be expelled through the exhaust. You should familiarize yourself with what is normal, so you can tell if the quantity increases.

And check for air leaks too – perform leak testing periodically and make sure everything is airtight. If you don’t have your own equipment, you can contact your service provider to rent a leak detector, or arrange an appointment for a leak check.

In an oil-lubricated vacuum pump, a very small quantity of oil may be expelled through the exhaust. You should familiarize yourself with what is normal, so you can tell if the quantity increases.

And check for air leaks too – perform leak testing periodically and make sure everything is airtight. If you don’t have your own equipment, you can contact your service provider to rent a leak detector, or arrange an appointment for a leak check.

Listen to your vacuum pump

How does your vacuum pump sound? Can you hear anything other than a humming noise – like a chattering or rattling? Older pumps may become slightly louder as they reach the end of their expected life, but any unexplained noises should be checked out as soon as possible. They could indicate something loose in the system, or that debris has entered somewhere it shouldn’t be.

How does your vacuum pump sound? Can you hear anything other than a humming noise – like a chattering or rattling? Older pumps may become slightly louder as they reach the end of their expected life, but any unexplained noises should be checked out as soon as possible. They could indicate something loose in the system, or that debris has entered somewhere it shouldn’t be.

Check the pumping speed

Conduct a check of the pumping speed. Is it still within the usual parameters? If it is lower, the pump requires maintenance, as something is affecting its efficiency.

Conduct a check of the pumping speed. Is it still within the usual parameters? If it is lower, the pump requires maintenance, as something is affecting its efficiency.

Conclusion

Skipping servicing may save time and money in the short term, but in the long term, it can be disastrous for your vacuum pumps and wallet alike. Only by conducting timely maintenance can your vacuum pump be used to its full potential and live a long and happy life. Scheduling your maintenance allows you to plan and minimize downtime, rather than leaving it to chance. It also ensures pump efficiency, saving you both energy and money.If you would like assistance to keep track of your servicing schedule, Busch will be happy to help. We offer service contracts for every process, meaning that we conduct the right maintenance at the right time, while you concentrate on your core business. With over 60 years of experience in the world of vacuum, you can be sure your vacuum supply is in safe hands. Our intelligent digital monitoring systems can also alert you to when something is not running as it should be – and immediately alert our service team, who will get your vacuum pump back to peak performance, almost before you’ve had time to register that there was a problem. Or let us evaluate your current process and show you where optimization is possible.