How ECOTORQUE improves your process

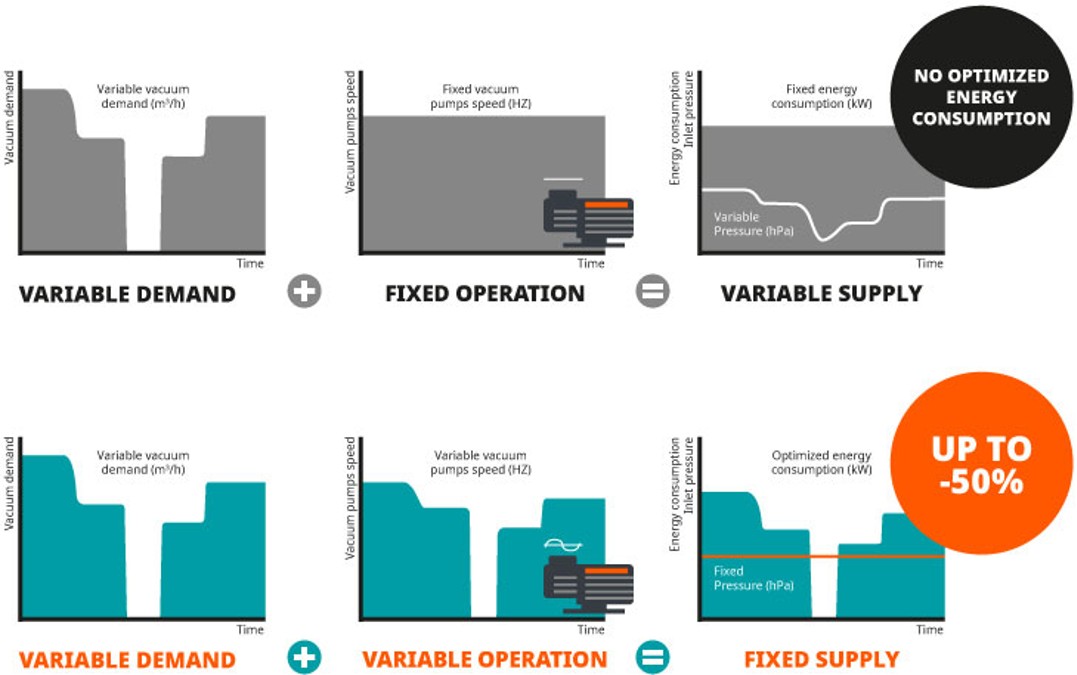

In most processes, the vacuum demand varies over time. In such applications, a vacuum pump operating at a fixed speed provides the maximum pumping speed required but will continue to provide the same pumping speed when the demand decreases.An ECOTORQUE vacuum pump adjusts its rotational speed to maintain a constant pressure level. When vacuum demand decreases, this results in reduced speed and optimized energy consumption. So why pay for a pump to operate all the time? Why not just pay for it when you need to use it? This is the right way. The Busch way.