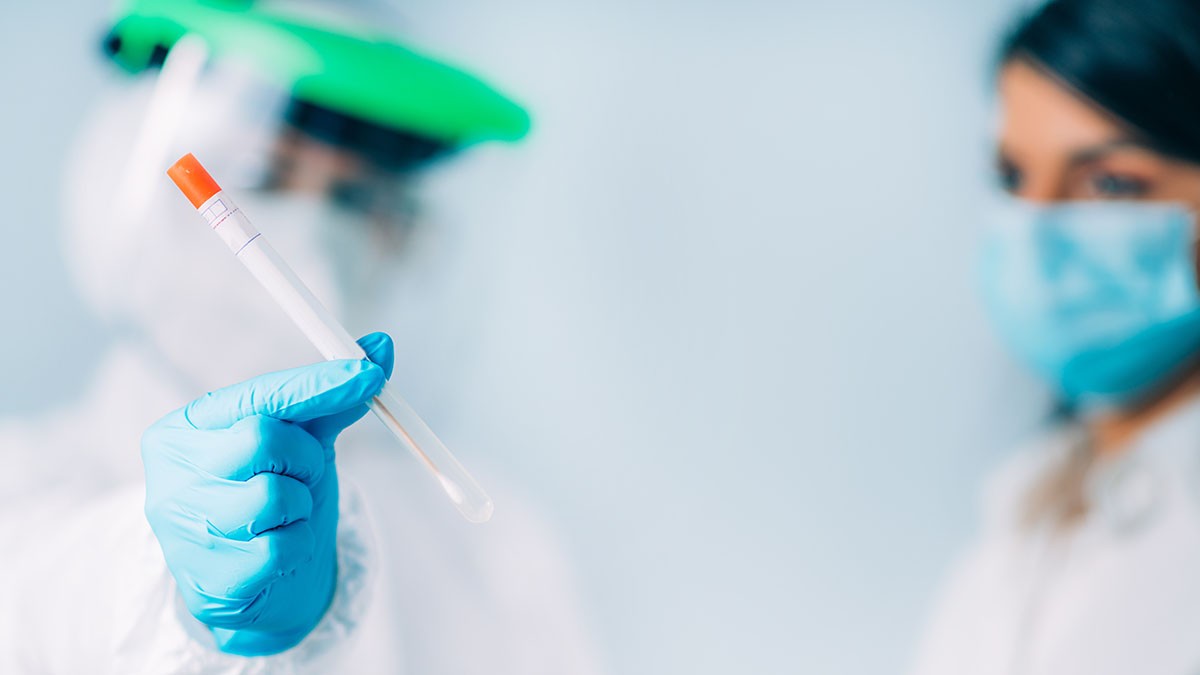

Source: © Microgen - stock.adobe.com.

Plastic Parts for Corona Test Kits Made with Vacuum

The corona pandemic is still present all over the world, and corona tests are an important measure to save lives and to help infected people promptly. According to the German Robert Koch Institute almost 2.8 million tests have been carried out in laboratories in Germany since the beginning of the pandemic.

The coronavirus is detected in swabs taken from mouth, nose or throat. Sensitive molecular test can find the viral genome in the smear. The demand for such test kits increased significantly over the past few weeks. They are made up of plastic precision parts which are manufactured with the use of modern vacuum technology.

A customer of Busch Vacuum Solutions in Germany needed support because of the higher demand for COVID-19 test kits. And Busch was able to deliver two vacuum systems within just a few days.

The vacuum systems with MINK claw vacuum pumps are used for the degassing of the molten material when producing plastic precision parts for the test kits. Parts such as caps and test tubes which have to be completely leak-tight. These tests are used in hospitals and specially equipped test centers for testing the suspected cases of COVID-19.

Luckily, most tests are negative and only around 9% of the tested people are infected with the virus. Usually the test result is available within 48 hours. With the help of these tests immediate measures can be taken to provide the best possible assistance and treatment to infected persons.