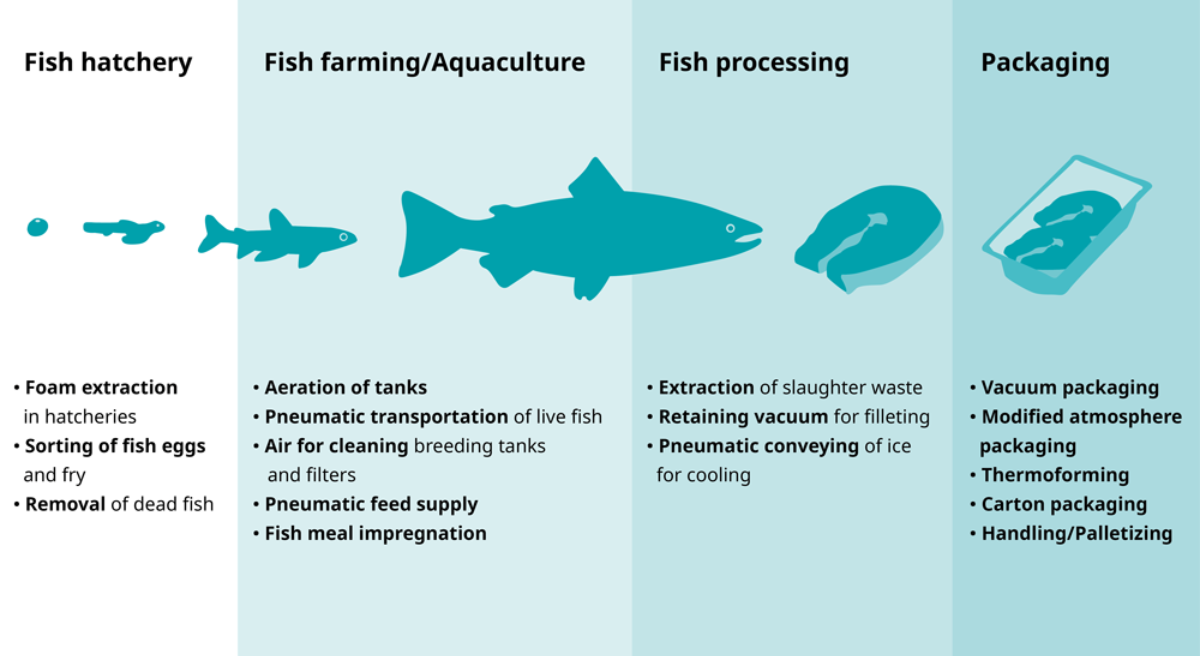

The role of vacuum in fish farming

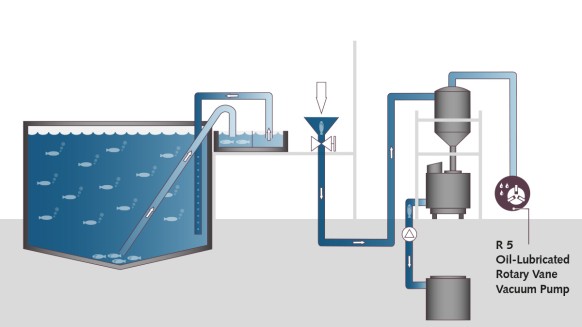

Farmed fish are accompanied by vacuum during their entire life cycle. From sorting the eggs and smolt in the hatchery to packaging the prepared fish, vacuum and overpressure play a crucial role.Overpressure is used to aerate breeding tanks and extract foam, while vacuum gently transports live fish and suctions out by-products as well as waste. And, at the end of the life cycle, the most common use of vacuum in fish farming is in the packaging of fresh fish.

For all areas of fish farming, from hatching to processing and packaging, we offer the right vacuum or overpressure technology.