It is essential to know the pressure range, required accuracy, gas composition, process and environmental conditions when selecting the vacuum gauge with the correct measurement principle for your process.

Your local Busch representative can help you choose the right gauge.

1. Pressure range and required accuracy

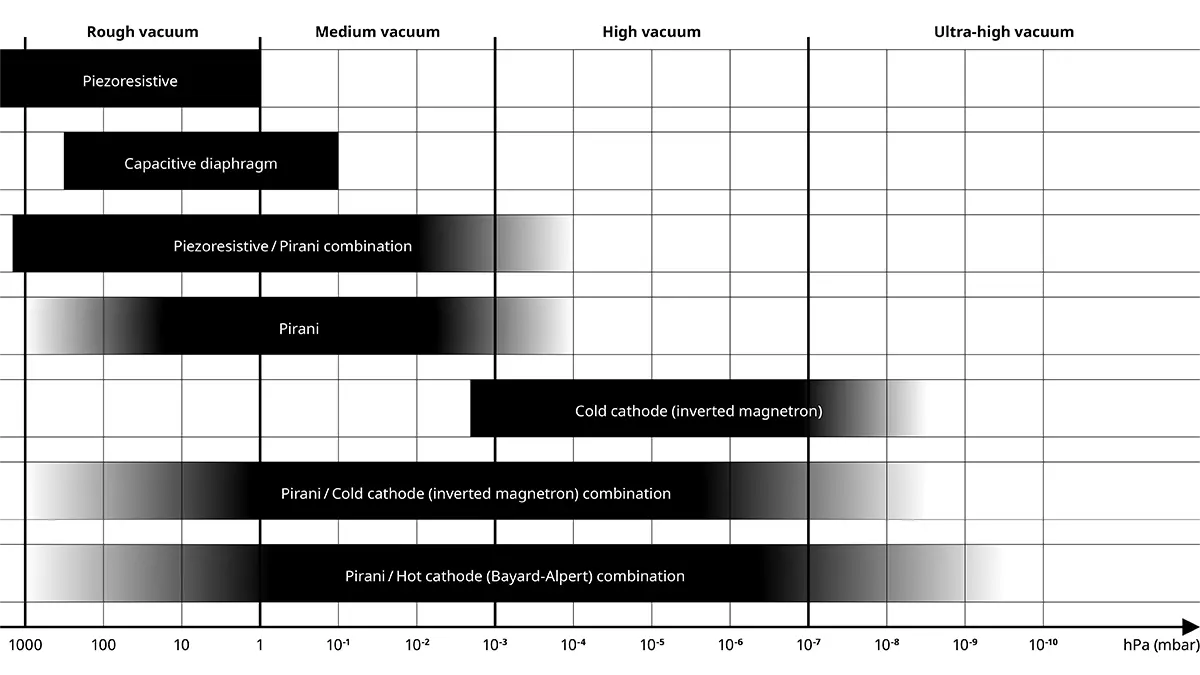

To obtain accurate readings of the vacuum level produced by your pump, the gauge must be able to measure within the range that corresponds to the pump’s performance. Otherwise, you could end up with a gauge that cannot measure within the vacuum range of your process. The chart below shows the pressure ranges covered by VACTEST. Depending on the pressure range, it may be necessary to combine different measuring principles in one instrument.

Measurement principle | Pressure Range | Accuracy |

|---|

Piezoresistive | 1600 – 1 hPa (mbar) | < 0.3% full scale |

Capacitive | 200 – 0.1 hPa (mbar) | < 0.25% full scale |

Pirani | 1000 – 1 · 10-4 hPa (mbar) | 1000 – 20 hPa (mbar): 30% from reading 20 – 2.0 · 10-3 hPa (mbar): 10% from reading |

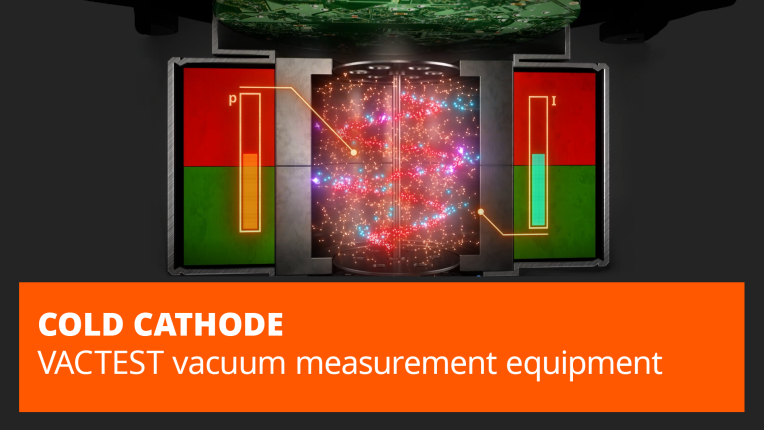

Cold cathode | 2 · 10-3 – 5 · 10-9 hPa (mbar) | < 25% from reading |

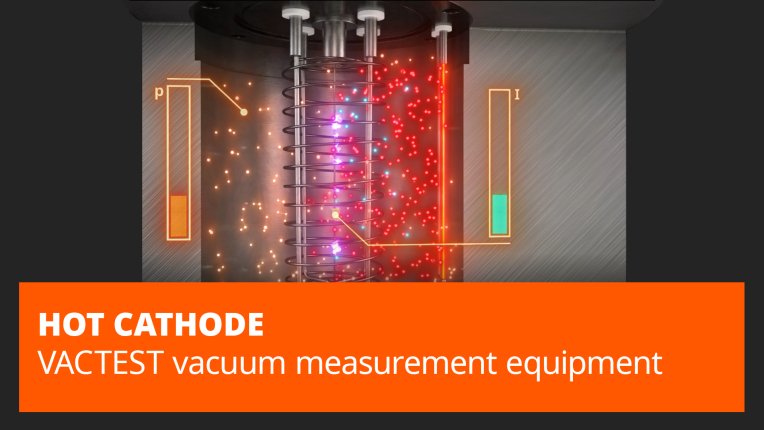

Hot cathode | 3 · 10-3 – 5 · 10-10 hPa (mbar) | <10% from reading |

2. Gas composition

The vacuum gauge has a sensor that may come in contact with the measured medium. Consider the reaction this contact can cause. For example, is the medium corrosive, does it solidify at a specific temperature, or could it leave deposits in the sensing element?

3. Process and environmental conditions

Think about the working conditions that your gauge will be in. Temperature, moisture, and dust can all affect accuracy and longevity.