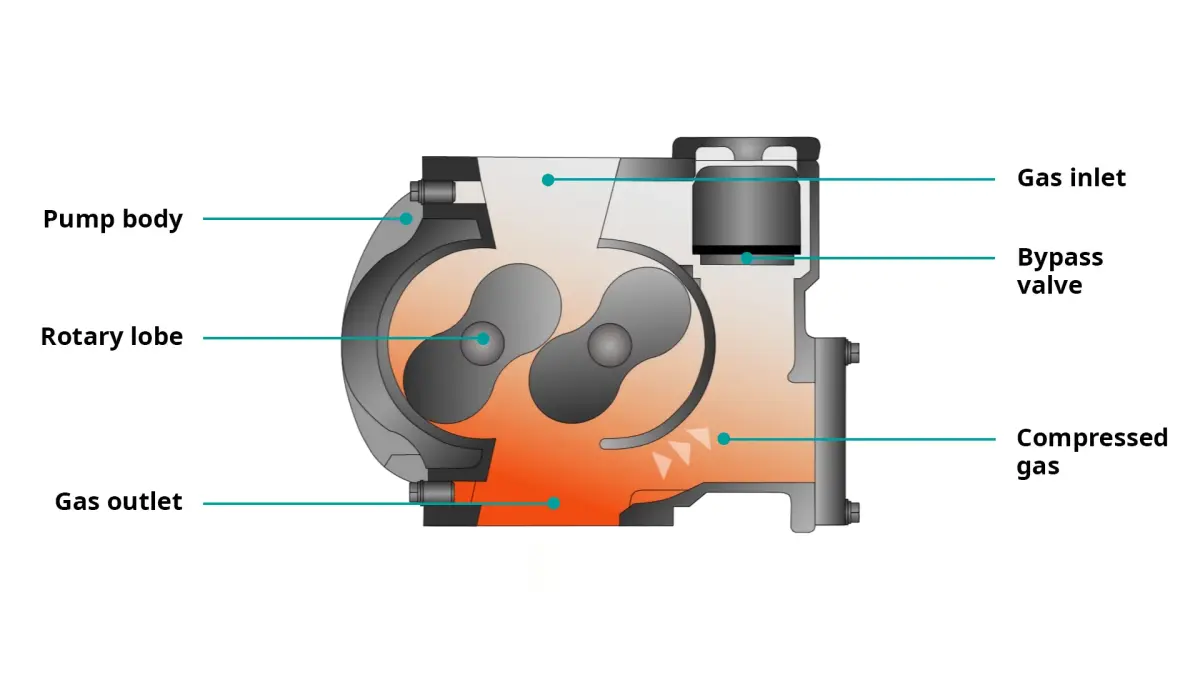

Types of vacuum boosters

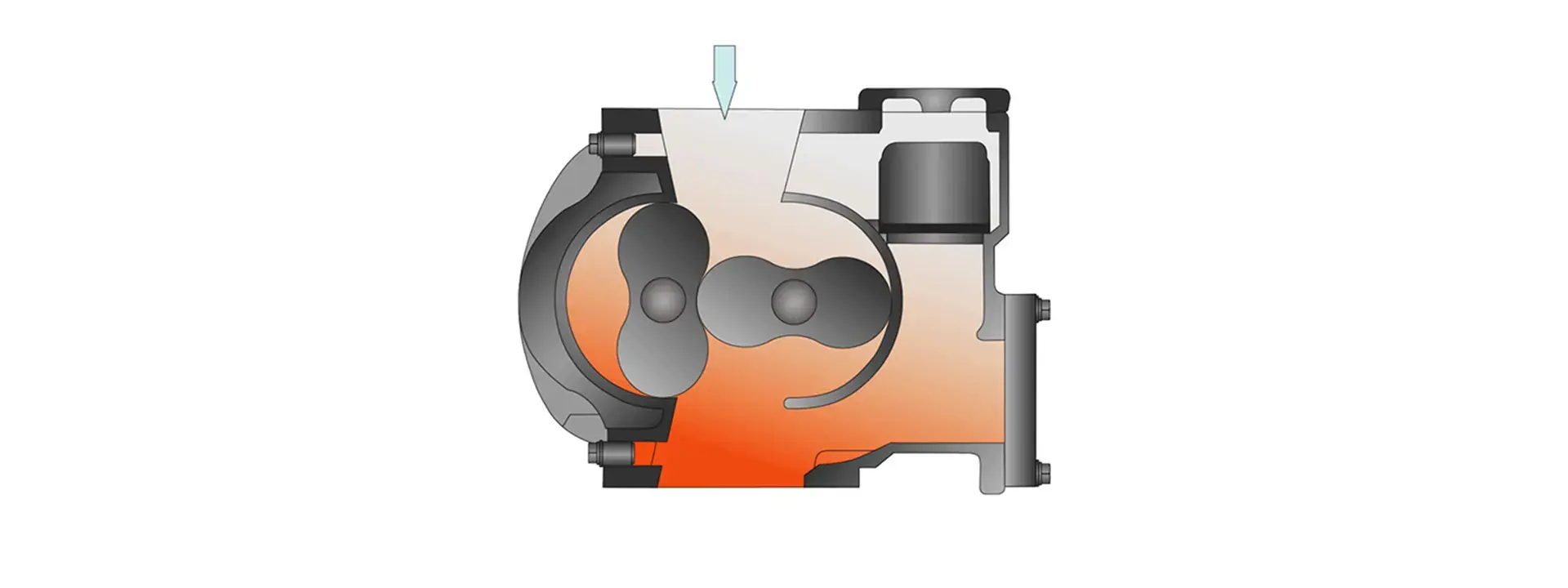

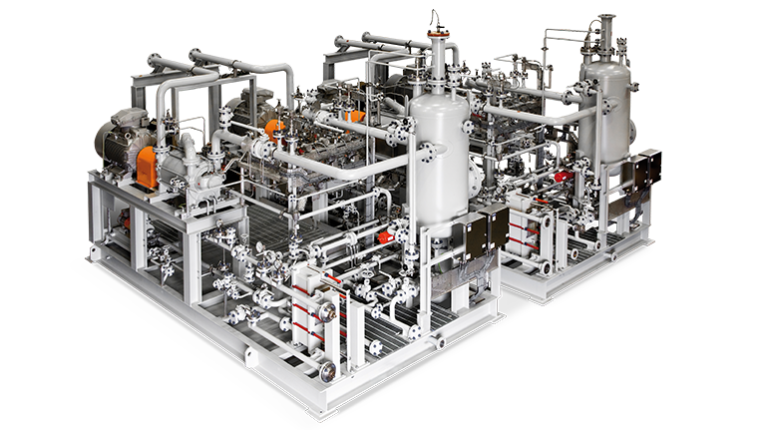

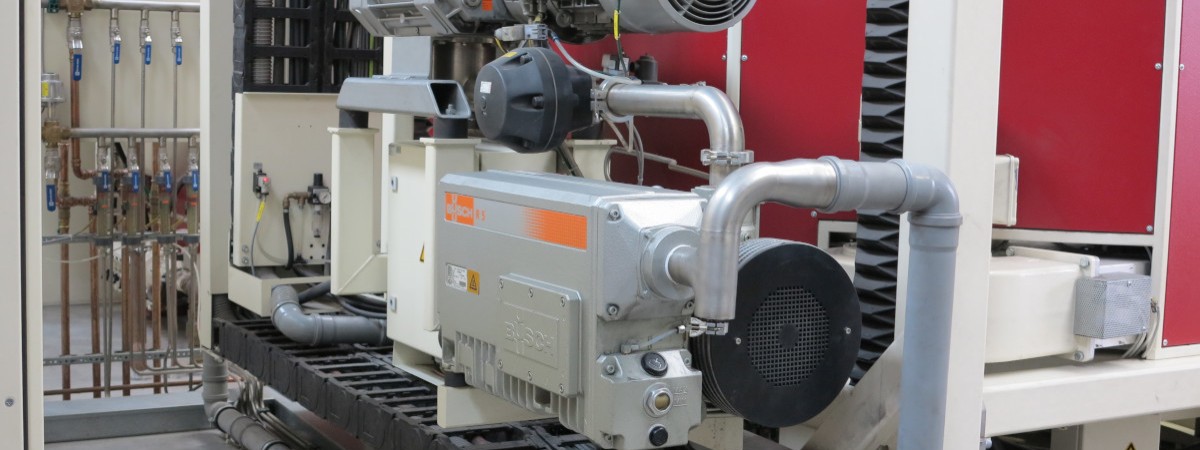

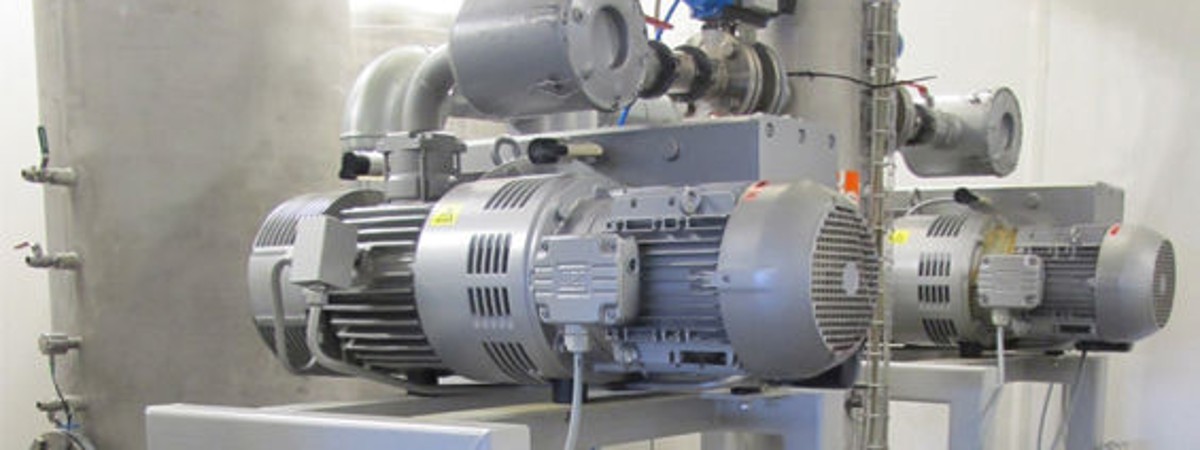

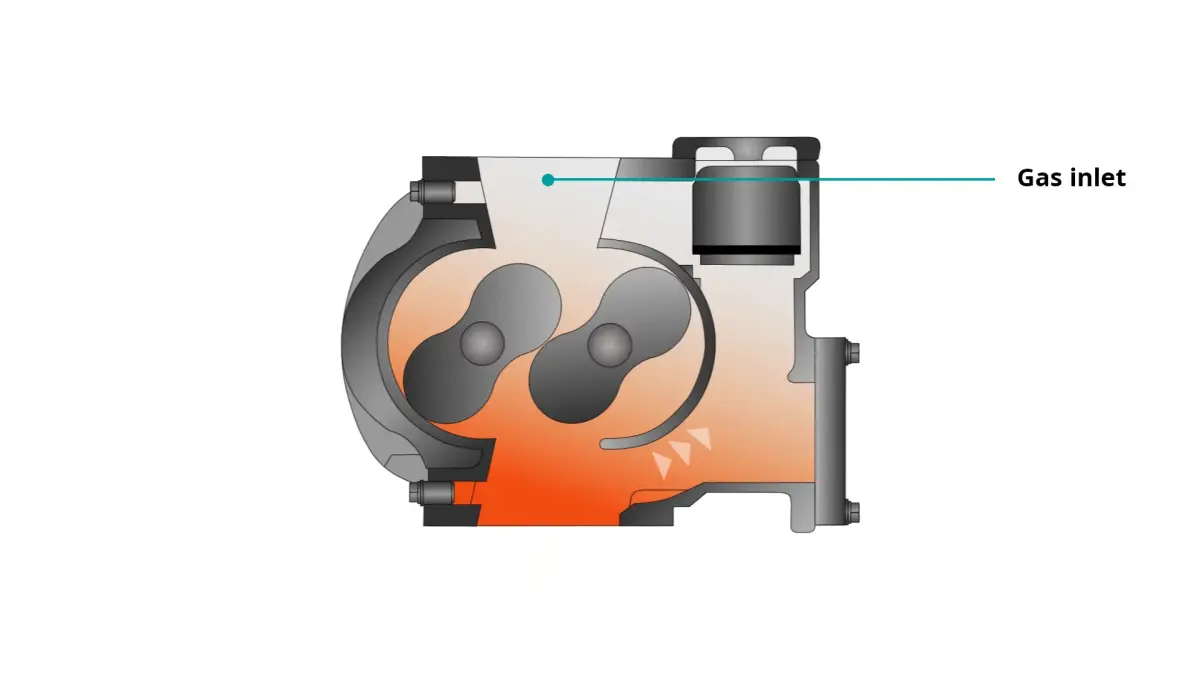

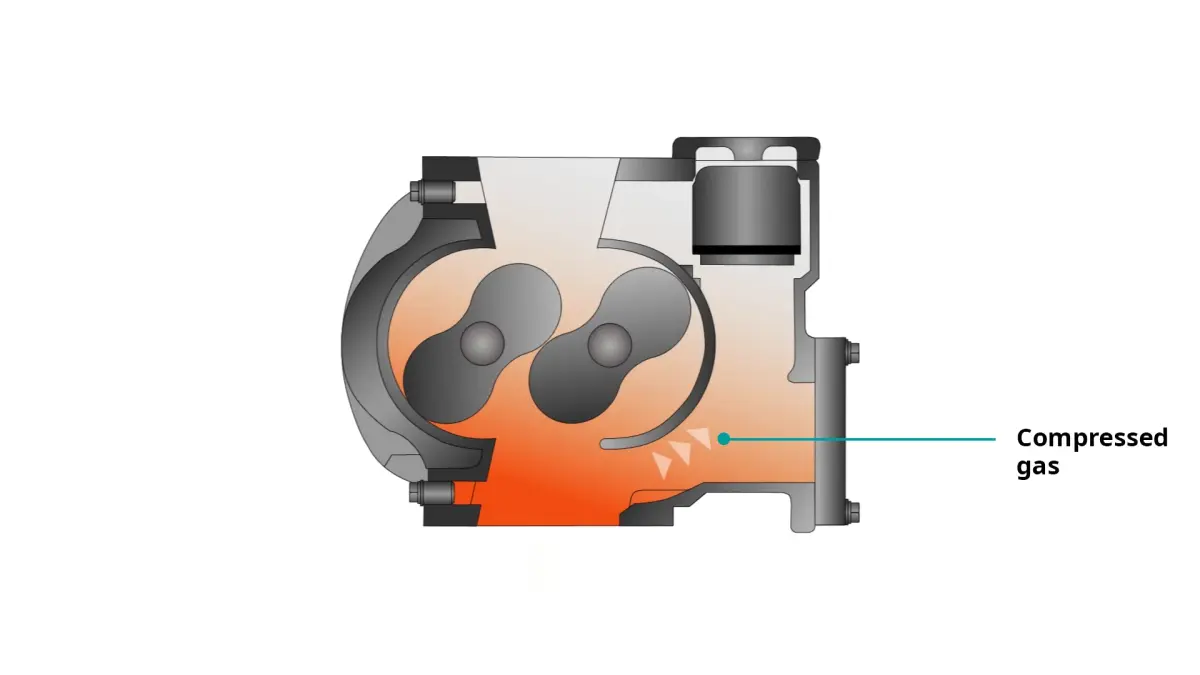

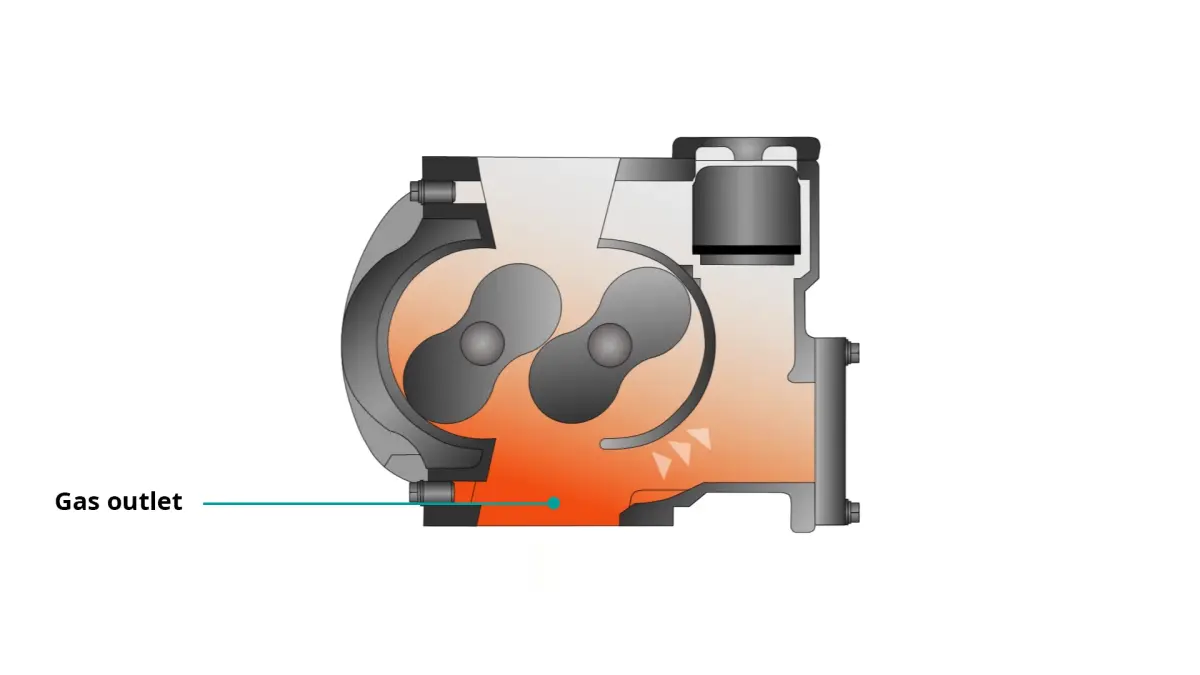

PANDA / PUMA vacuum boosters from Busch increase the pumping speed and ultimate pressure of vacuum pumps. They can boost the performance of vacuum systems by up to a factor of ten.Product series | Mechanical features | Nominal pumping speed | Type |

|---|---|---|---|

PANDA WV | Bypass valve | 250 m³/h – 4,500 m³/h | industry |

PANDA WZ | Bypass valve | 500 m³/h – 3,600 m³/h | gas-tight |

PUMA WP | No bypass valve | 260 m³/h – 4,500 m³/ | industry |

PUMA WY | No bypass valve | 500 m³/h – 8,000 m³/h | gas-tight |