Osland Havbruk production and process of water recycling

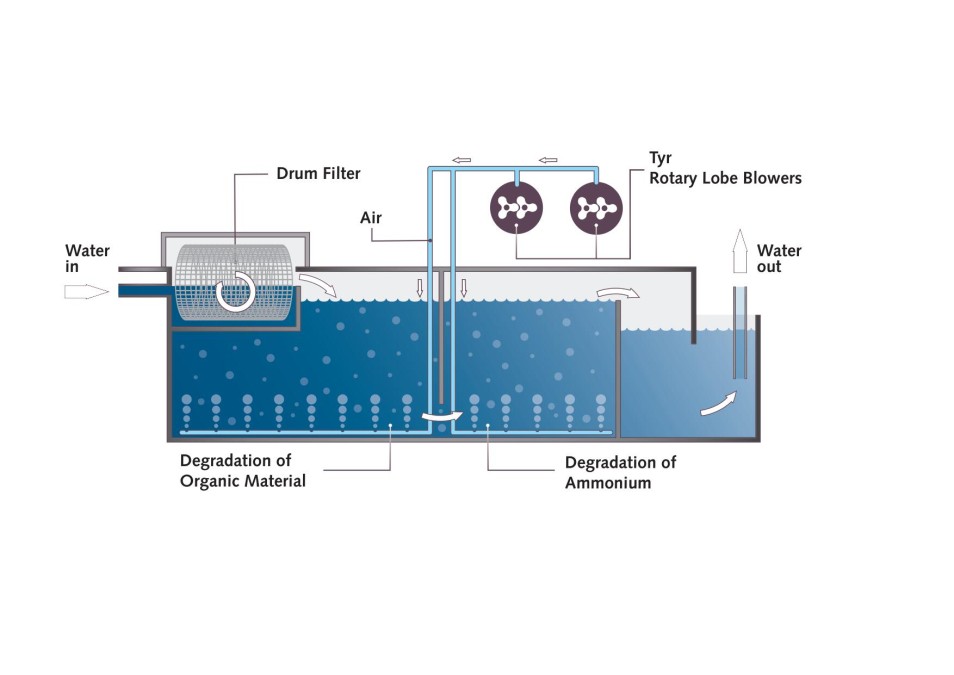

The RAS facility at Osland Havbruk AS was developed and built by one of Norway's leading suppliers in the field of production water recycling. The facility is split into two sections, handling the fry and smolt areas, respectively. Each area consists of six holding tanks. The tanks for the fry are each six metres in diameter, with a total water volume of 339 cubic metres. The tanks for growing the smolt are 10 metres in diameter, containing 1272 cubic metres of water in total. Water recirculates at the rate of 2800 m3 per hour. After six months of operation [November 2016], production manager Kjetil Rørtveit is able to confirm that only two per cent of the total water volume consists of added fresh water. The new RAS means that Kjetil Rørtveit is not dependent on the seasons and can produce under ideal conditions all year round. Salmon can therefore grow from the egg stage into smolt three to four times a year, allowing 3.5 million smolt to be reared annually.- The recirculating aquaculture system (RAS) is equipped with one water treatment plant for fry and one for smolt (Fig. 1).

- These consist of two mechanical drum filters that filter out dirt particles larger than 40 microns in size in two stages, before draining them off as slurry.

- This is followed by the actual biological water treatment in the biofilter, which is based on MBBR (moving bed biofilm reactor) technology.

- After leaving the drum filters, the water enters a tank. This tank contains the biomedium (Fig. 2), designed to obtain the largest possible surface area for the smallest possible volume.

- The medium is home to a wide range of microorganisms which break down or convert the organic substances dissolved in the water. The biofilter's microorganisms convert harmful ammonium/ammonia into nitrites and nitrates.

Our solution of oxygen dispense

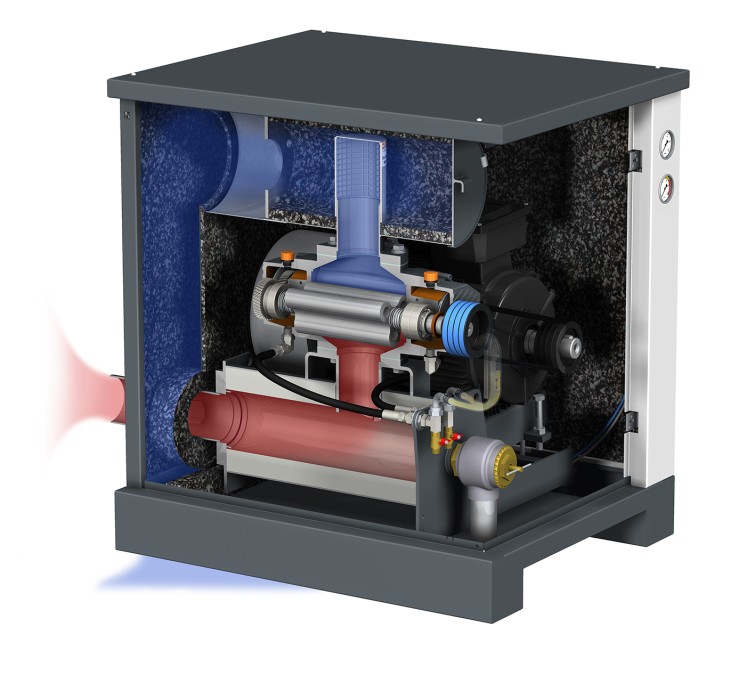

A permanent supply of oxygen is critical to the growth of microorganisms. The RAS facility uses a TYR rotary lobe blower from Busch. Two of these blowers (Fig. 3) are installed directly on each of the two biofilters. The blowers are therefore always in operation, one alternating with the other, ensuring the biofilter is supplied with compressed air, which enters the tank at the bottom. In addition to providing oxygen enrichment, the compressed air keeps the water and the buoys in constant motion as it rises through the water.Production manager Kjetil Rørtveit is extremely happy with the blowers. He is particularly impressed with how quiet and reliable the TYR rotary lobe blowers are. In their first six months of operation, the blowers have not developed any faults or broken down.