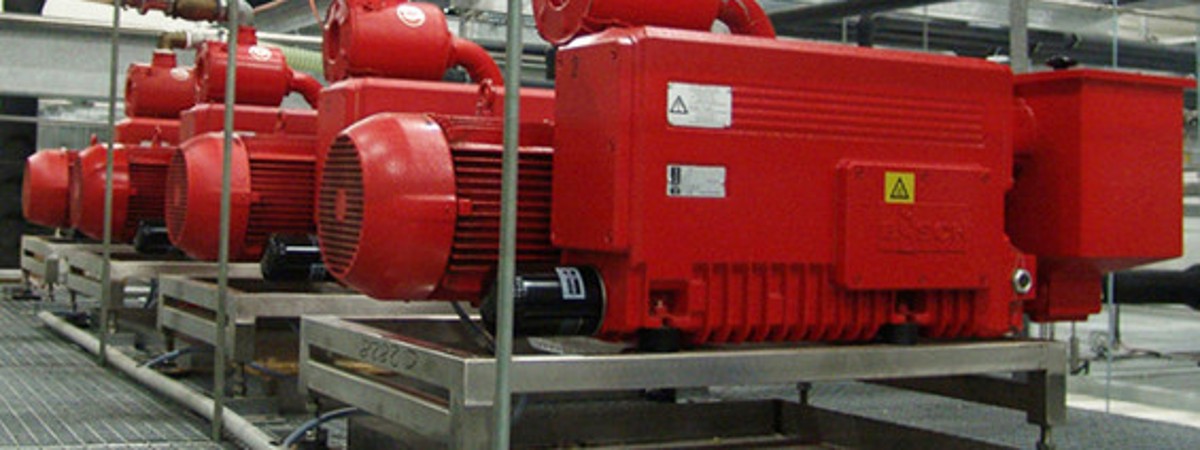

Getting to know you and your requirements

This very important initial step is to examine and understand your business’ challenges and expectations.Your local Busch expert will visit you on-site and together with you will discover the best solution for your individual needs. Based on

questions like: what is the most suitable pump technology? What is the scope of the customized vacuum system?

Ultimately, it is about the vacuum technology that meets your requirements…exactly.