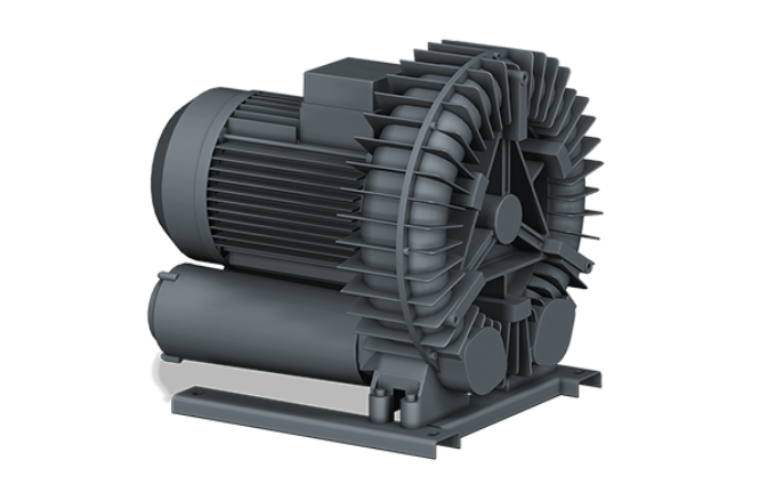

SAMOS

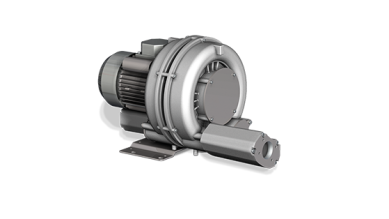

Side channel blowers

SAMOS side channel blowers are the ideal choice for all applications, where a pulsation-free volume flow is required. They can be used to generate vacuum and overpressure.

These side channel blowers are available as single- and two-stage versions. Their die-cast aluminum or cast-iron construction makes them very robust.

SAMOS side channel blowers have a dynamically balanced impeller made of aluminum alloy. Thus, they generate very low vibration and noise levels.

The large variety of sizes gives you the opportunity to choose the perfect SAMOS for any application, both technically and economically. An extensive range of accessories completes the portfolio.

Operating principle

SAMOS side channel blowers transfer kinetic energy of a rotating impeller to the pumped medium and convert it into pressure.The impeller is mounted directly on the shaft of the motor. Together with the specially shaped housing it forms the side channel.

The pumped medium is suctioned in and compressed in the side channel. Single-stage SAMOS discharge the pumped medium after one rotation. Two-stage SAMOS convey it to the second stage after one rotation. Here, it is compressed again and discharged afterwards. This leads to higher differential pressures.

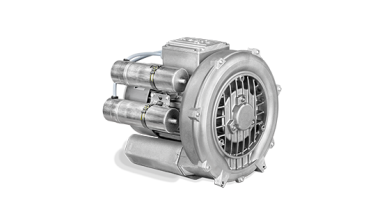

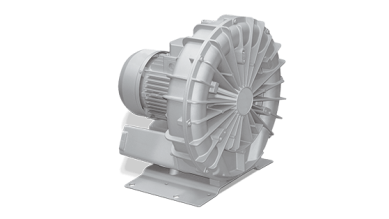

SAMOS SB

- Robust construction

- Reliable performance with an exceptional high uptime

- Very low noise levels

- High differential pressures and pumping speeds

- Minimal maintenance

- Dry and contact-free operation

- UL/CSA-certified

Benefits of the SAMOS SB series

SAMOS SB side channel blowers demonstrate their reliability every day in a variety of processes. They are used for pneumatic conveying, aeration, analytical applications, holding and lifting, carton folding and packaging as well as printing industry applications.

The robust design makes SAMOS SB mechanically stable against imbalances. The impeller bearing is located inside the cover for less wear and to avoid bearing failures. The open impeller construction prevents particles from being accumulated to avoid imbalances and protect the bearing.

They are characterized by operational reliability and minimal maintenance or downtimes thanks to their dry and contact-free operating principle.

Through high-precision manufacturing SAMOS SB side channel blowers achieve high differential pressures and high pumping speeds in their performance class.

Lifetime-lubricated bearings and contact-free impellers make SAMOS SB nearly maintenance-free.

Thanks to internal silencers, SAMOS SB are characterized by very low noise levels. This makes them the ideal choice for an installation in the immediate vicinity of workstations.

All SAMOS SB products

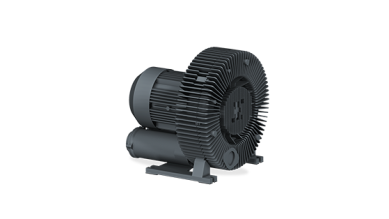

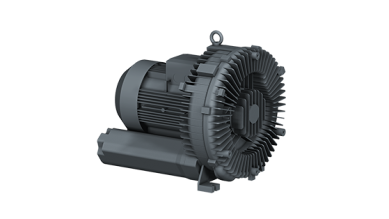

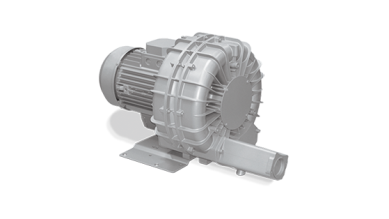

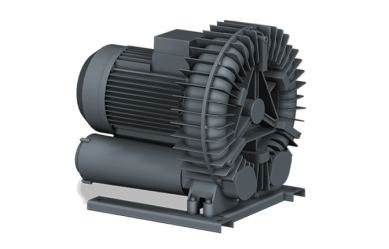

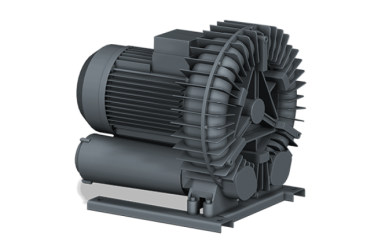

SAMOS SI

- Robust construction

- Reliable performance with an exceptional high uptime

- Low noise levels

- High differential pressures and pumping speeds

- Nearly maintenance-free

- Dry and contact-free operation

- cCSAus-certified

Benefits of the SAMOS SI series

SAMOS SI side channel blowers demonstrate their reliability every day in a variety of processes. They are used for pneumatic conveying, aeration, analytical applications, holding and lifting, carton folding and packaging as well as printing industry applications.

The impeller bearing is located between impeller and motor. Thus, the stage can be accessed without touching the impeller. So, you always have an easy access to the stage for repair.

The open impeller construction prevents particles from being accumulated to avoid imbalances and protect the bearing.

They are characterized by operational reliability and minimal maintenance thanks to their dry and contact-free operating principle.

Through high-precision manufacturing SAMOS SI side channel blowers achieve high differential pressures and high pumping speeds in their performance class.

The standard thermal protection provides additional security against overheating.

Lifetime-lubricated bearings and contact-free impellers make SAMOS SI nearly maintenance-free.

Thanks to internal silencers, SAMOS SI are characterized by very low noise levels. This makes them the ideal choice for an installation in the immediate vicinity of workstations.