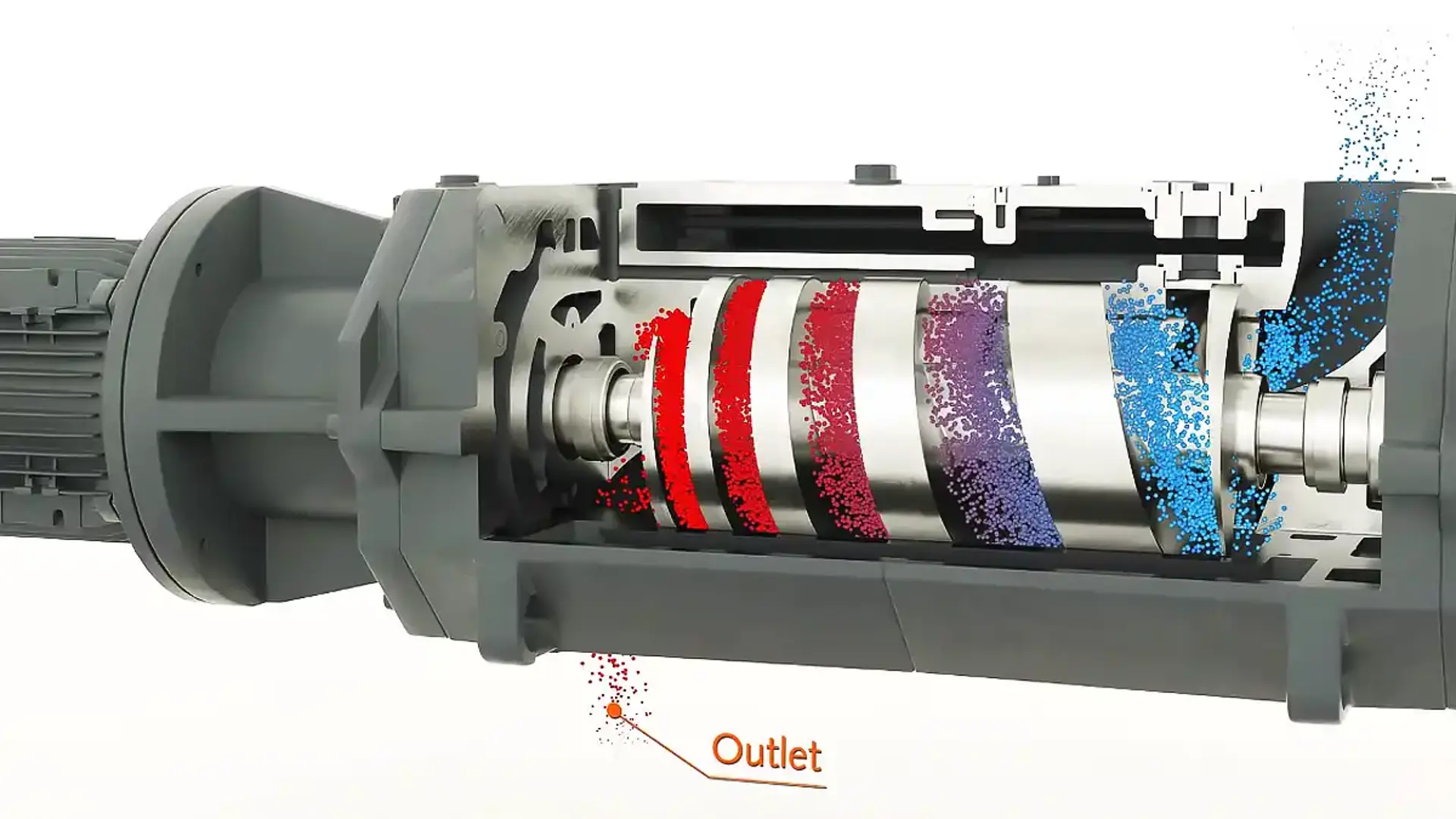

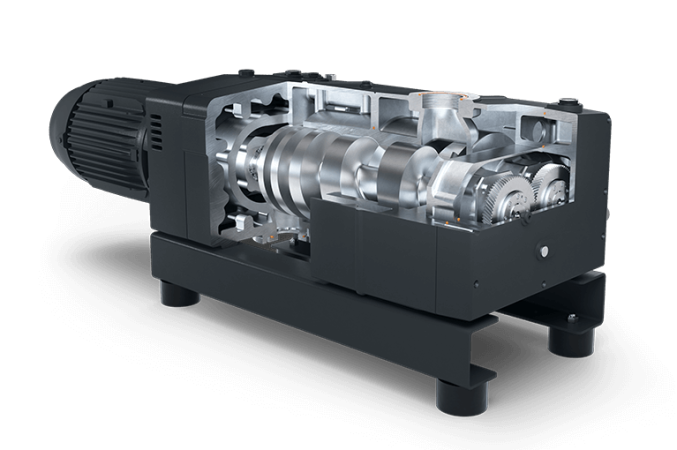

Types of dry screw vacuum pumps

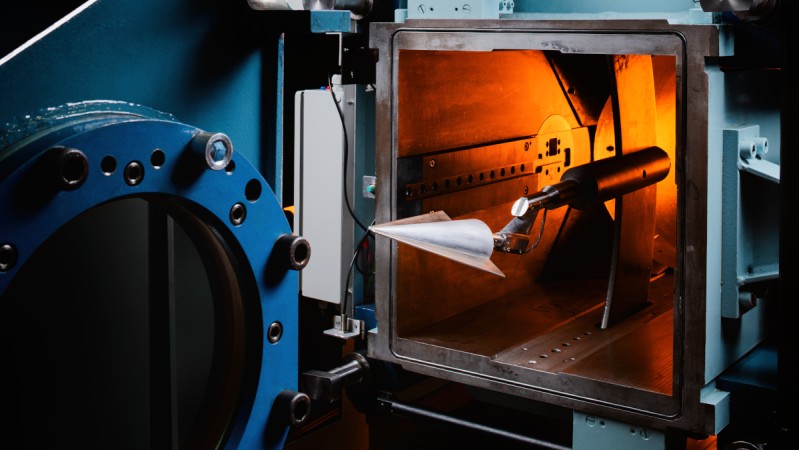

COBRA Industry dry screw vacuum pumps are ideally suited for industrial applications requiring reliable and contaminant-free extraction of gases and vapors.Looking for a dry screw vacuum pump for demanding processes, such as coating or semiconductor manufacturing? Explore COBRA Semicon from Pfeiffer Vacuum+Fab Solutions (member of the Busch Group).

Product series | Nominal pumping speed |

|---|---|

COBRA NX | 350 m³/h - 950 m³/h |

COBRA NC | 110 m³/h – 2,500 m³/h |

COBRA NS | 70 m³/h - 600 m³/h |

COBRA NF | 750 m³/h - 950 m³/h |

COBRA DX PLUS | 650 m³/h - 1,900 m³/h |

COBRA DS | 70 m³/h - 1,640 m³/h |

COBRA DH | 2,700 m³/h - 6,200 m³/h |

COBRA BA | 85 m³/h - 105 m³/h |