Fig. 1: The Norddeutsche Seekabelwerke (NSW) sites are located directly on the Weser River in Nordenham (Germany). Source: Norddeutsche Seekabelwerke (NSW).

Hose Extrusion with Dry Vacuum Technology

Norddeutsche Seekabelwerke

The production of undersea cables is the core competence of Norddeutsche Seekabelwerke, which belongs to General Cable. The insulation layer and gelcoat around the cable strands are made of polyethylene (PE). These PE coatings are applied directly to the cable strands by hose extrusion. Dry MINK claw vacuum technology is deployed in this process and only demand-controlled MINK MV claw vacuum pumps are used that reliably maintain the desired vacuum level during the entire production process and thus make a significant contribution to the high product quality.

About Norddeutsche Seekabelwerke

Norddeutsche Seekabelwerke (NSW) was founded as early as 1899. The first undersea cable with a length of 7,993 kilometres was laid in 1904. NSW has been completely owned by General Cable Corporation since 2007 and is the competence centre for undersea cables within this international group of companies at its original site in Nordenham/Weser (Fig. 1). With its own pier and cable-laying ships, the undersea cables can be "wound" from the factory directly onto the ships, driven to the area of operation and laid there.Nowadays, NSW produces undersea cables with a length of up to 10,000 kilometres. NSW's main product is medium and high voltage cables that are laid under water. The range extends from transatlantic cables to the cabling of offshore wind farms, connections from islands to the mainland and cables laid across lakes or rivers. Cables for telecommunications or optical cables as well as copper cables for motor windings are also part of the product range.

Hose extrusion

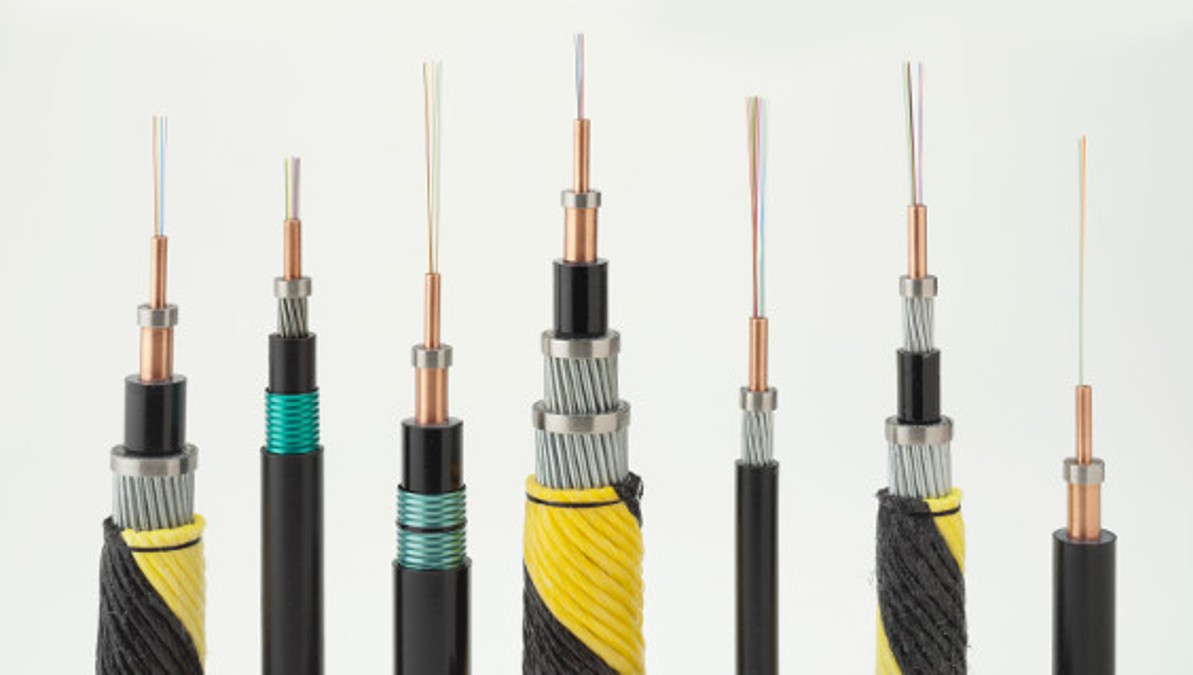

NSW currently uses three single-screw extruders for hose extrusion, which operate with a screw diameter of 45 to 150 millimetres. This is mainly used to manufacture intermediate products, i.e. individual cables that are later processed together with other cables to form an undersea cable. Depending on the product (Fig. 2), three different PE coatings are applied simultaneously around a copper strand using a mould.- The first layer is a thin PE coating that smoothes the surface of the copper strand.

- The actual insulation layer is made of a different PE plastic.

- As mechanical protection a further PE plastic layer is extruded onto the copper conductor as a third coating.

During this process, vacuum is permanently applied directly in the mould in the cavity between the strand and the coating. It ensures that the three layers cling directly to the strand or directly to each other and that no air inclusions occur.

-

Fig. 2: Undersea power cables in two different versions with PE coatings. Source: Busch Vacuum Solutions.

In the past, NSW used liquid ring vacuum pumps on the extruders, which proved to be extremely maintenance-intensive and unreliable. These vacuum pumps each had a 7.5 kW motor as drive and could not be adjusted. It was only possible to set the vacuum level manually via a false air valve.

The water used to operate the vacuum pumps caused problems. A tank was installed in the water circuit in order to keep the amount of water as high as possible. As the melts are extruded at temperatures of 200 to 210 degrees Celsius, the water still heated up to almost 100 degrees Celsius in some cases. A larger tank was installed and thus the amount of water was further increased; however, this did not really help to solve the problem.

The lowest ultimate pressure is achieved at temperatures of approximately 15 degrees Celsius. Higher temperatures have a negative impact on the ultimate pressure.

A further complication was that the water often had to be changed because monomers and particles accumulated in it. They had an aggressive effect on both the vacuum pumps and the material in the entire water circuit, meaning that parts had to be repeatedly replaced. Vacuum pump failures also caused downtime in the extrusion process.

The water used to operate the vacuum pumps caused problems. A tank was installed in the water circuit in order to keep the amount of water as high as possible. As the melts are extruded at temperatures of 200 to 210 degrees Celsius, the water still heated up to almost 100 degrees Celsius in some cases. A larger tank was installed and thus the amount of water was further increased; however, this did not really help to solve the problem.

The vacuum level attainable using liquid ring vacuum pumps is directly dependent on the water temperature.

The lowest ultimate pressure is achieved at temperatures of approximately 15 degrees Celsius. Higher temperatures have a negative impact on the ultimate pressure.

A further complication was that the water often had to be changed because monomers and particles accumulated in it. They had an aggressive effect on both the vacuum pumps and the material in the entire water circuit, meaning that parts had to be repeatedly replaced. Vacuum pump failures also caused downtime in the extrusion process.

The new vacuum solution

Two claw vacuum pumps (Fig. 3) are now installed on each of the three extruders. NSW opted for this vacuum technology because it had already been used for many years in pneumatic material feeding to the extruders with positive results.MINK claw vacuum pumps are used in this process to generate the vacuum for suction conveying of the granulate. This has shown how reliable and economical MINK vacuum pumps are. The MINK MV sizes now used for hose extrusion operate completely redundantly and are controlled in such a way that they are operated alternately.

Due to the length of the cables produced, an extrusion process can take up to one week. This means that during this time the vacuum is permanently maintained and the preset ultimate pressure is precisely maintained. Leaks during the feeding of the strands into the extrusion mould can cause higher or lower amounts of air leakage.

The frequency-controlled drives of the MINK MV vacuum pumps ensure that the set point is maintained by changing the speed. Manual control is no longer necessary. Each individual vacuum pump is preceded by a separator that makes sure no entrained plastic particles can enter the vacuum pumps. The drive power of the MINK MV vacuum pumps is 2.1 kilowatts each, which is considerably lower than that of the liquid ring vacuum pumps with 7.5 kilowatts each previously used.

-

Fig. 3: MINK MV claw vacuum pump with integrated frequency controller for demand-dependent control of ultimate pressure and pumping speed. Source: Busch Vacuum Solutions.

The decision to install the new MINK MV vacuum pumps in May 2017 has proven to be the right one. The six MINK MV claw vacuum pumps operate completely trouble-free and efficiently. Maintenance is limited to emptying or cleaning the upstream separators and to an annual gear oil change on the vacuum pumps.