Source: Capua 1880.

High-Quality Essential Oils and Essences Thanks to Vacuum Distillation

Capua 1880 uses vacuum technology from Busch Vacuum Solutions for the distillation processes, which are carried out in thin-film evaporators or short-path distillers depending on the type of fruit. All the distillers use only COBRA screw vacuum pumps that are free of operating fluids. The frequency-controlled vacuum pumps precisely and reliably guarantee the required vacuum level which, together with the temperature, ensures the desired product quality.

About Capua 1880

Capua 1880 has been producing essences from citrus fruits since 1880. The company has two production plants located in Calabria, in the middle of the world's largest bergamot growing area, a cross between lemon and bitter orange, which was specially bred for the production of essential oils.Over 96 percent of the world's production of bergamot is grown in Calabria, while Capua 1880 is the world's largest producer of natural essences from this fruit. However, oils are also extracted from lemons, oranges, blood oranges and mandarins. Between October and May, the citrus fruits are harvested and processed at Capua 1880's Reggio Calabria plant. The extraction of the oil is similar for all citrus fruits.

The essential oils containing water are extracted mechanically from the fruit skins on 12 production lines. First, the remaining solids and then the water are separated from this emulsion in the downstream multistage centrifugal separators. The raw oils extracted in this way are refined throughout the year at the Campo Calabro plant and mixed for individual customers according to the desired recipe in order to always obtain the same fragrance.

In addition to state-of-the-art production, thorough quality control ensures that the essential oils correspond precisely to the specifications of the various customers.

95 percent of the bergamot essences produced in this way are used in perfume production. Many of the world's best-known perfume manufacturers use bergamot oil from Capua 1880 as the top note for their perfumes. The remaining five percent is used in the beverage industry for flavouring.

Distillation Process

The raw oils extracted in the first stage are refined on a total of five distillation lines and then temporarily stored in a controlled atmosphere. Distillation of the essential raw oils must be carried out as carefully as possible so that the scents are not influenced. As early as the late 1990s, Capua 1880 therefore decided to switch the vacuum supply of its thin-film evaporators and short-path distillers to dry COBRA screw vacuum technology from Busch. The liquid ring vacuum pumps previously used only achieved a vacuum of 40 to 60 millibar. A higher temperature was therefore required for evaporation. This was 80 to 90 degrees Celsius for thin-film evaporators, depending on the type of fruit.Our solution

All thin-film evaporators are now equipped with COBRA screw vacuum pumps, which maintain a much higher permanent vacuum. The advantage in this case is that the distillation processes can be carried out at ambient temperature.Varying ambient temperatures or different oils can mean that fine adjustments of the operating vacuum and the pumping speed of the vacuum pump are required. This is possible simply by regulating the frequency-controlled motor of the vacuum pump.

-

Fig. 2: Short-path distiller for obtaining essential oils from citrus fruits. Source: Capua 1880.

-

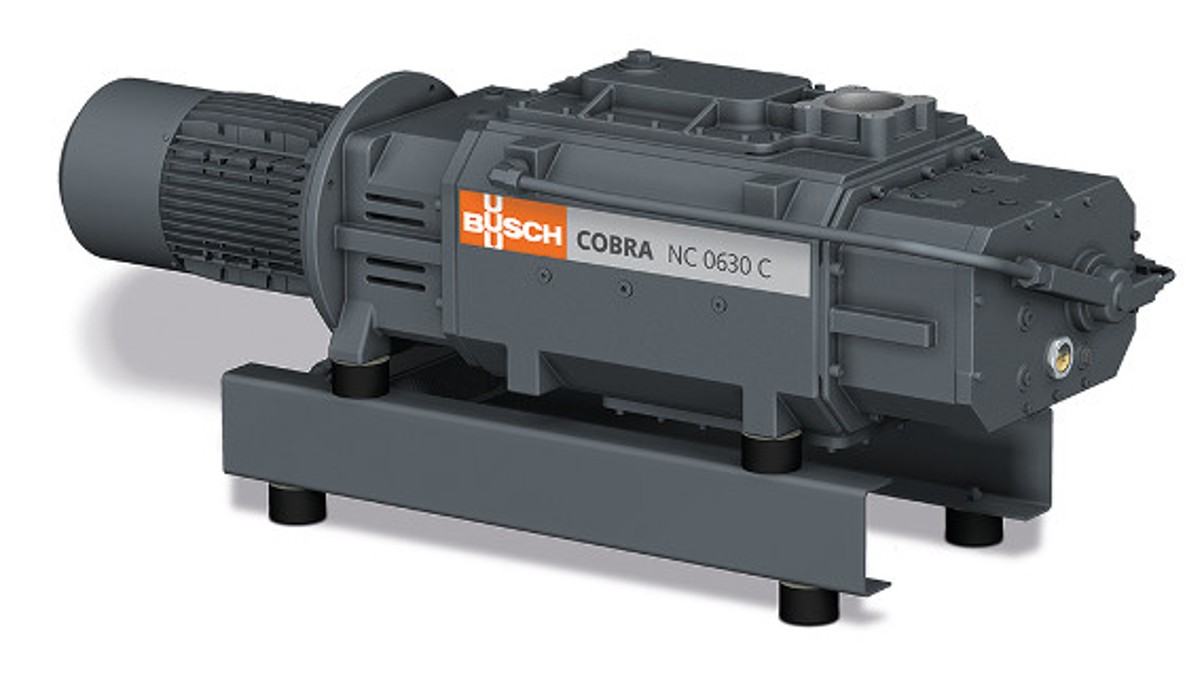

Fig. 3: COBRA screw vacuum pumps are used as backing pumps in thin-film evaporators and short-path distillers. Source: Busch Vacuum Solutions.

The major difference to the previously used liquid ring vacuum pumps is that COBRA screw vacuum pumps do not require any operating fluid to compress the process gas. This is why it is called a "dry" screw vacuum pump.

-

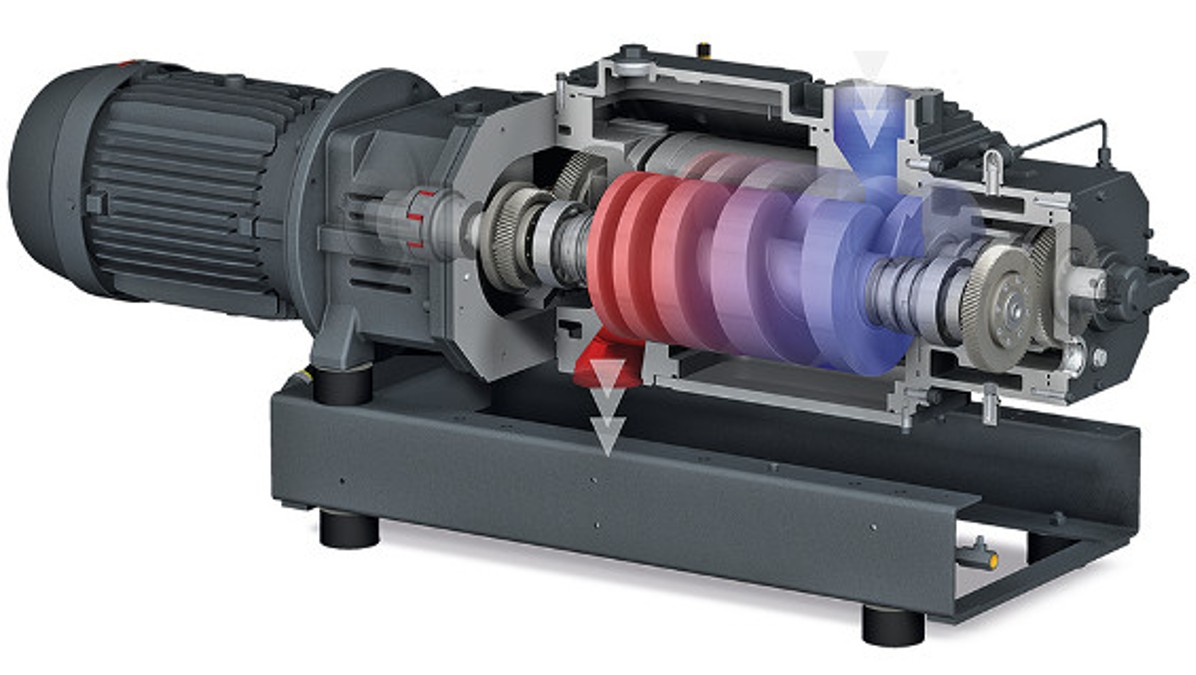

Fig. 4: COBRA screw vacuum pumps run without operating fluids. Source: Busch Vacuum Solutions.

COBRA Screw Vacuum Pumps

In COBRA screw vacuum pumps, two screw-shaped rotors rotate in opposite directions (fig. 4). The extracted vapours are trapped between the cylinder and screw chambers, compressed, and transported to the gas outlet. During the compression process the screw rotors do not come in contact with each other or the cylinder. Precise manufacturing and minimal clearance between the moving parts enable this operating principle and, in addition, guarantee a low ultimate pressure of <0.1 mbar.COBRA screw vacuum pumps operate using water cooling, which ensures an even temperature distribution throughout the pump body and thus thermal stability in the entire process. Due to the variable pitch in the screw coils, the process gas is pre-compressed. The advantage of this is that both gas temperatures and the power consumption of the vacuum pump are reduced significantly. Generally, dry screw vacuum pumps operate at higher temperatures than liquid ring vacuum pumps. This prevents condensation of the vapours in the vacuum pump, eliminating the possibility of contamination with an operating fluid.

-

Fig. 5: Highest purity of the finished products through the distillation process: The sight glass in the foreground shows the distilled end product; in the background the oil extracted from the fruit skins of the blood orange. Source: Busch Vacuum Solutions.

Benefits for Capua 1880

The switch from liquid ring to dry screw vacuum technology has tremendous benefits for Capua 1880.- The quality assurance of the essential oils produced has been considerably simplified.

- Quality impairments caused by higher temperatures during the distillation process can be eliminated completely.

- Distillation at low pressures, precisely adjusted to the product, allows the process to run under optimum conditions and guarantees the best results for the fragrance.

- This also produces a completely clear, colourless oil (fig. 5).

Getting rid of the liquid ring vacuum technology means that the operating fluid water and thus the costs for it and the additional expenditure for maintenance work were also eliminated.

Capua 1880 has signed a service agreement with Busch. It stipulates that a Busch service technician will inspect and service the COBRA vacuum pumps and vacuum systems once a year. Further maintenance work is not necessary.

Capua 1880 is confident that it took the right decision two decades ago when it switched to Busch's COBRA screw technology. This has also created a new quality standard in the production of essential oils from citrus fruits.