Future proofing the Food Industry with optimal vacuum

The leading industrial sector in the world is a major consumer of water and energy. It also produces important quantities of organic waste and solid waste such as plastic, glass and paper. Conditioned by changing food habits, demographic growth and an increase in living standards, the main challenge facing the sector is to successfully meet growing customer demands for elaborate, safe and nutritious food and beverages while reducing its resource consumption and controlling environmental, social and societal impacts. An optimal vacuum supply can play its part in tackling those challenges and in future proofing the food industry.1. Reducing costs to remain competitive

Producing crude oil and refined products at a lower cost to stay competitive on the market is one of the industry’s major challenges. Optimizing production systems and environmental utilities on currently operating sites is therefore a priority for the oil industry. This maximizes production efficiency, reduces the costs of extraction and refining and thereby offsets the exploration costs.

2. Improving performance to ensure the valorization of assets

To sustain their supply of crude oil or gas, oil companies are looking to extend the life of mature sites but are also compelled to seek new sources of oil or gas for which extraction, transport and refining are much more complex and costly. For that, they aim to achieve 100% reliability of their plants : no unplanned shutdowns , increased throughput , secure industrial assets.

3. Improving the Environmental footprint to meet increasingly stringent standard

The oil and gas industry is a major consumer of water and energy resources and is therefore subject to increasingly stringent environmental standards. This constrains them to rethink extraction, production and distribution methods in order to obtain or maintain their licence to operate. They also have to provide guarantees and ensure transparency in the environmental management of their activities.

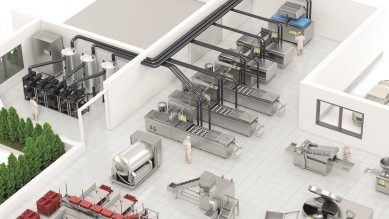

Vacuum solutions for the food industry

With over forty years of experience in the electric power industry and installations all over the world, Busch offers vacuum technology for all applications in electric power generation to tackle today’s and tomorrows challenges. Main applications are:-

Condenser exhausting

- With the Dolphin liquid ring vacuum pump series, Busch provides a tailored solution for condenser exhausting which includes different construction materials, nominal pumping speeds up to 6,475 ACFM (11,000 m3/h), and standard vacuum systems.

- Hogging is the initial evacuation of the condenser to a pre-defined vacuum level prior to turbine start-up. Since high pumping speeds are often required, Dolphin liquid ring vacuum pumps are used for this application as well.

-

Turbine gland steam removal

- To prevent air ingress to the turbine, steam is injected into the turbine glands and removed by a vacuum system. This is especially important during start-up on the high pressure side of the turbine, and on the low pressure side during operation.

- This gland system handles steam passed through the seals and any non-condensables accumulated along the way.

- Pumping water vapor and non-condensables is an ideal application for Dolphin liquid ring vacuum pumps.

- An alternative solution is also the Aqua version of Mink claw vacuum pumps for humid processes.

-

Priming and holding

Non-condensable gases trapped in surface condenser waterboxes, cooling tower tubes, cooling water pumps or water turbines can render such equipment inefficient or even ineffective. Busch provides claw and liquid ring vacuum technology to help initially fill equipment with water (priming) and evacuate non-condensables while on process (holding). Standard vacuum systems can be fully automated and designed for harsh outdoor conditions.

From a Standard Product to an Individual Solution for Every Application

We offer you a wide selection of technologies for vacuum generation in the field of plastics processing.Plastex extruder degassing systems

Plastex degassing systems are standardized modules for degassing the vapours in the extruder screw zone. Depending on the process, extruder and material, Mink dry claw vacuum pumps or Dolphin liquid ring vacuum pumps are used. In the case of large throughputs, COBRA dry screw vacuum pumps are installed in Plastex vacuum systems. Puma or Panda vacuum-boosters are used as boosters.

Combi extruder degassing systems

Combi systems are individual vacuum technology solutions for melt degassing during extrusion. They are designed by Busch engineers in accordance with the relevant extruder/process. The same components are used as on Plastex vacuum systems.

Our matching products for the food industry

When it switched to COBRA screw technology, we have created a new quality standard in the production of essential oils from citrus fruits.

| TYR rotary lobe blowers (overpressure) | TYR rotary lobe blowers (vacuum) | MINK dry claw cavuum compressors | MINK dry claw vacuum pumps | SAMOS | DOLPHIN | R5 | SECO | |

| Foam extraction in hatcheries | ✓ | ✓ | ✓ | |||||

| Sorting of fish eggs | ✓ | |||||||

| Ventilation of breeding tanks | ✓ | ✓ | ✓ | ✓ | ||||

| Cleaning of band and drum filters | ✓ | ✓ | ✓ | ✓ | ||||

| Gas input to breeding tanks | ✓ | ✓ | ✓ | ✓ | ||||

| Pneumatic transportation of live fish | ✓ | ✓ | ✓ | |||||

| Air input for cleaning breeding tanks | ✓ | ✓ | ✓ | ✓ | ||||

| Pneumatic feed supply | ✓ | ✓ | ✓ | |||||

| Extraction of slaughter waste | (✓) | (✓) | ✓ | ✓ | ||||

| Retaining vacuum for filleting | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Vacuum for transportation | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Pneumatic suction conveying of ice for cooling | ✓ | ✓ | ||||||

| Vacuum packaging | ✓ | ✓ | ||||||

| MAP packaging | ✓ | ✓ | ||||||

| Thermoforming | ✓ | ✓ | ||||||

| Carton packaging | ✓ | (✓) | ✓ | |||||

| Handling / Palletizing | ✓ | (✓) | ✓ |

My decision to centralize the vacuum supply was the right one – from an economic point of view and for the sake of the environment!