Busch News & Media

Pre-cooling lettuces reliably, thanks to cutting-edge vacuum technology

Pre-cooling lettuces reliably, thanks to cutting-edge vacuum technology

Heekeren GbR

Maulburg, Germany

|

10.02.2021

|

4,5 min

Vacuum cooling for vegetables and leafy greens directly after harvesting is a common approach to quickly and reliably cool these foodstuffs, and thus guarantee high-quality products over an extended storage period. To achieve proper cooling, the company

Heekeren GbR has first started using the modern

COBRA PLUS screw vacuum pump from Busch Vacuum Solutions to pre-cool iceberg lettuce.

The benefits of this technology are manifold:

The vacuum pump is

frequency-controlled, enabling its output to be adjusted to actual demand, as well as reducing cooling times and energy consumption. Thanks to its oil-free operation, any water vapor suctioned into the vacuum pump cannot mix with the oil – which has an exceptionally positive effect on the required maintenance effort.

About Heekeren GbR

Jörg Heekeren developed his business to specialize in the cultivation of iceberg lettuce.

In the space of one season, the company produces over 10 million heads of iceberg lettuce. It also cultivates other varieties of lettuce, including romaine. The majority of the lettuces are sold wholesale within Germany and eventually make their way to shoppers via discount stores and supermarket chains.

Vacuum drying process

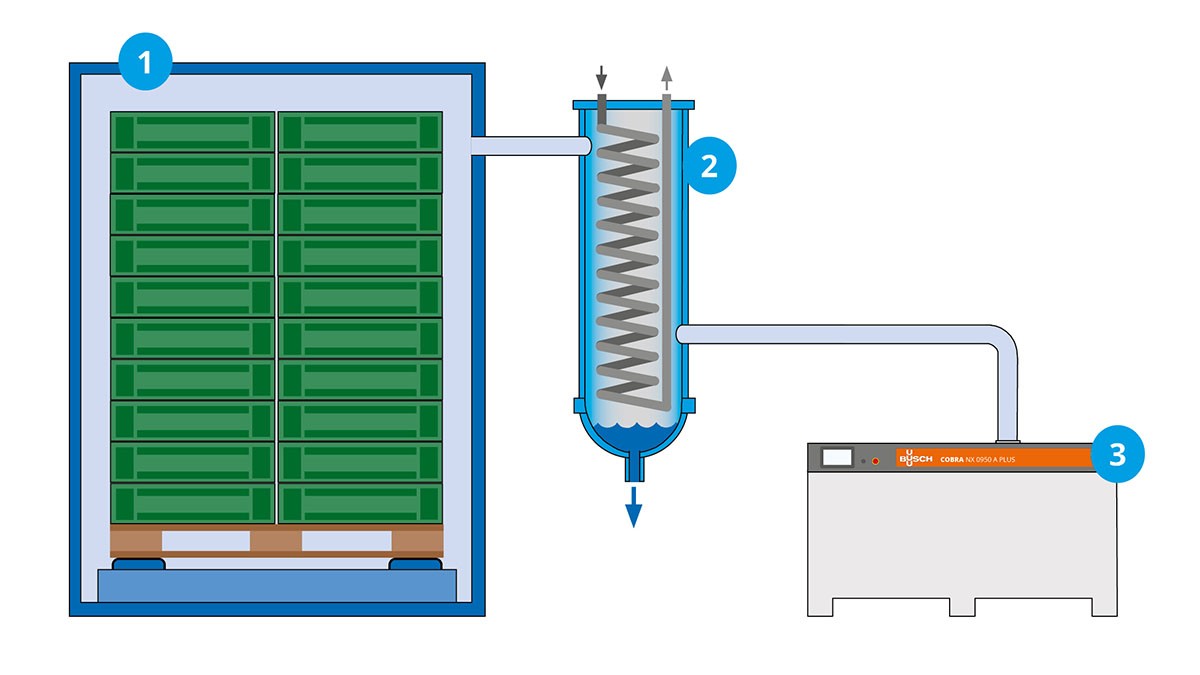

To guarantee the longest possible shelf life without any losses in quality, Jörg Heekeren has been relying on vacuum cooling for eight years already. As soon as they are harvested, the lettuces are put in crates, which are then placed on pallets and transported to the vacuum chamber (Fig. 1).

The vacuum chamber is designed to hold eleven europallets stacked with lettuce crates, reaching a total height of almost three meters.

Once loading via a roller conveyor is complete, the chamber is closed and vacuum is applied. This means that the air is suctioned out of the chamber. Due to the vacuum, any

moisture in and on the lettuce starts to evaporate and is extracted from the chamber as water vapor. Because the water's aggregate state changes from liquid to gas, heat is removed from it, thus cooling the lettuce.

Depending on the external temperature and quantity, this process lasts between 20 and 35 minutes. The benefit of this method is that, apart from quickly cooling the lettuces to 3° Celsius, it cools them from the inside out, which speeds up the process once again. What’s more, less moisture is lost than in conventional air cooling.

After the required cooling temperature is reached, the vacuum chamber is ventilated, the lettuce is removed and then transported to a refrigerated warehouse for interim storage. The challenge for the vacuum technology here is that water vapor is also suctioned out of the vacuum chamber along with the air. For this reason, the mixture of air and water vapor is fed through a cold trap upstream from the vacuum pump. Here the air is cooled, condensing out the water vapor (Fig. 2).

The aim of this process is to ensure that no water vapor makes its way into the downstream vacuum pump. Given the size of the vacuum chamber at Heekeren, three parallel oil-lubricated rotary vane vacuum pumps were connected. With this setup, any water vapor that was not fully condensed out via the cold traps led to problems, as some of the water would mix together with the operating fluid oil in the vacuum pumps. As a result, more maintenance effort was needed due to oil and filter changes.

Process improvement

In view of these circumstances, Jörg Heekeren was looking for a way to improve his system. Working together with the supplier of the vacuum cooling system and Busch Vacuum Solutions, he found a solution.

At the start of the harvesting season in April, a COBRA PLUS screw vacuum pump was installed so that it could be tested throughout the entire lettuce season. Because this type of vacuum pump does not require any oil lubrication in the compression chamber, there were no problems with water vapor.

The COBRA PLUS ran for the entire season until the end of October without any disruptions. No maintenance work was needed. As such, there were no costs incurred by maintenance work or wearing parts.

Benefits of frequency-control

Since the COBRA PLUS is

frequency-controlled, it adapts its pumping speed to actual demand. This means that, at the beginning of the vacuum chamber's evacuation phase, when as much air as possible needs to be quickly extracted, the motor runs at a high rotational speed. Once the pressure in the chamber drops, the vacuum pump automatically reduces its speed. This has the benefit that

less energy is consumed than with an unregulated motor, which runs at full speed more or less the entire time.

Less energy is consumed than with an unregulated motor, which runs at full speed more or less the entire time.

At 50 Hertz with a nominal motor rating of 18.5 kilowatts, the COBRA PLUS needs less power than the rotary vane vacuum pump, which was driven by an unregulated 22-kilowatt motor.

Control for the COBRA PLUS is connected to the overall system control. Once the operator has pressed the start button, the entire cooling process is completely automatic.

Thanks to the demand-driven control, it was also possible to reduce cooling times. This means that the capacity of the vacuum cooling system was increased.For Jörg Heekeren, the COBRA PLUS is the ideal vacuum pump for guaranteeing a long shelf and storage life for his lettuces, without any losses in quality.

Maulburg, Germany

|

10.02.2021

|

4,5 min