Busch News & Media

Energy Savings and Reduction of Carbon Dioxide Emissions Thanks to Centralization of Vacuum Supply

Energy Savings and Reduction of Carbon Dioxide Emissions Thanks to Centralization of Vacuum Supply

Block House Fleischerei GmbH

Block House Fleischerei GmbH has made increasing energy efficiency and reducing greenhouse gas emissions its declared objective. The producer of portioned fresh meat products and burgers has achieved considerable energy savings and reduced CO

2 emissions by 36.1 tonnes per year by reorganizing the vacuum supply for five vacuum lines. The core component of the new vacuum supply is a

centralized vacuum system from Busch. Thanks to its design and intelligent control system, it consumes significantly less energy than the vacuum pumps previously installed directly in the

packaging machines.

About Block House

In 1973, the Block House butchery was founded by Eugen Block and the quality standards Block set back then still apply today; the IFS certification confirms the high quality of the fresh meat and burger products. The prime beef quality seal additionally guarantees that the meat used only comes from cows that were raised in a way that is appropriate to the species. The meat for the steaks mainly comes from Angus and Hereford cattle.

The Block House butchery feels the same responsibility for the environment and sustainability as it does for maintaining strict quality standards. The energy management system is certified according to ISO 50001 and is part of the "Companies for Resource Conservation" project in Hamburg.

Thermoforming packaging machines

As early as 2013, the vacuum supply of the packaging machines was analyzed with regard to energy and it was determined that there should be savings potential here. At that time five packaging lines, each with one thermoforming machine, were each equipped with a

rotary vane vacuum pump as a backing pump and an additional

vacuum booster. These vacuum pumps were installed close to the packaging machines and thus in close proximity to the workplaces. The result was that the vacuum pumps emitted their waste heat directly into the production areas. It was only possible to maintain the low room temperature required for hygienic reasons by increasing the output of the air conditioning system. The noise pollution in the workplace was a further disadvantage.

In addition to saving energy and reducing CO

2 emissions, the Block House butchery had an additional goal for the replacement of the vacuum supply: they also wanted to guarantee high availability of the vacuum supply and remove the vacuum pumps from the production areas to avoid waste heat and noise pollution in the workplace. Furthermore, maintenance personnel should not enter these areas if possible.

Our solution

Together with the vacuum specialists from Busch, a concept was developed to find an energy-efficient solution that would also ideally eliminate all the other previous disadvantages. The team quickly agreed that central vacuum supply of the packaging machines would be the ideal solution. The basis for designing the centralized vacuum system was the five existing thermoforming packaging machines, which only require vacuum for the actual packaging process because the base foils are not sucked into the forms with a vacuum, but are rather blown into the forms with compressed air.

The new centralized vacuum system (fig. 3) has been in operation since September 2015. Its main components are four

R5 rotary vane vacuum pumps with four

PANDA vacuum boosters. One vacuum module consisting of one rotary vane vacuum pump and one vacuum booster has a purely stand-by function and is only used if maintenance must be performed during operation. The centralized vacuum system is one floor down, located underneath the production areas in a separate room and is thus completely separated from production.

The packaging chamber is evacuated in two steps with two vacuum supply lines. There is a constant so-called rough vacuum of 30 millibars in the one line. This enables fast evacuation to this "rough vacuum level". Once this has been achieved, the system switches to the second line with a vacuum level of 4 millibars. This two-stage pressure equalization method facilitates short cycle times. There are buffer tanks between the centralized vacuum system and the packaging machines to ensure that the required vacuum level is constantly available in the lines.

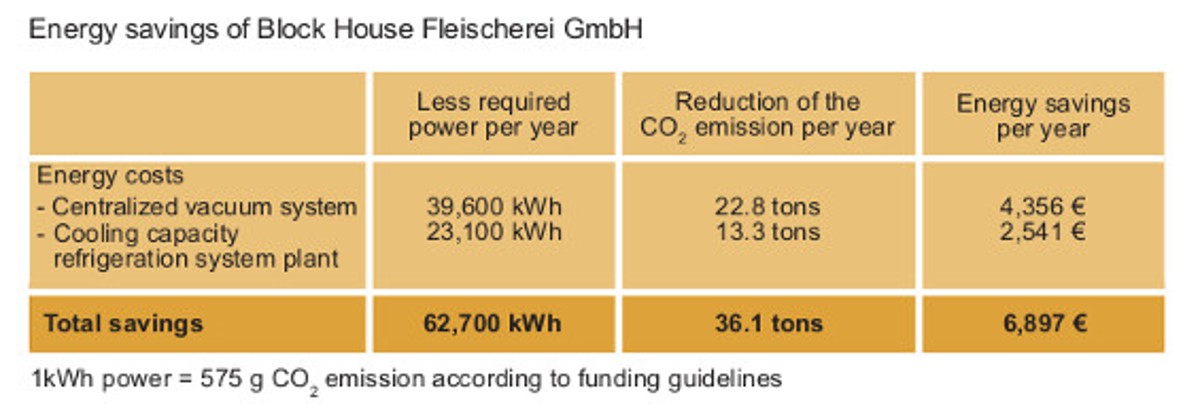

The system is operated according to demand. The individual vacuum modules are switched on or off depending on the pressure using pressure transmitters. Thanks to this control and 9.9 kilowatts less energy consumption than the previous decentralized supply, the Block House butchery has 4,356 euros in energy cost savings each year. The energy saved is equivalent to 22.8 tonnes of CO2 emissions (fig. 4).

Benefits of the central vacuum supply

Frank Damast, technical director at Block House butchery, is convinced that he installed the most advanced vacuum technology with the new centralized vacuum system from Busch and that this is also far superior to the previous vacuum supply when it comes to the level of maintenance and susceptibility to failures.

The modular design makes it virtually impossible for the vacuum supply to fail. The stand-by vacuum module also offers an additional element of security.

Energy Savings and Reduction of CO2 Emissions

The installation of the vacuum system in a separate room on a lower level enables savings of 23.100 kWh of cooling output for the cooling unit in the production areas. This corresponds to annual cost savings of 2,541 euros or reduces the CO

2 emissions by 13.3 tonnes. If the energy cost savings of the centralized vacuum supply and the cooling output are added together, it comes to annual total savings of 6,897 euros. The total reduction of CO

2 emissions comes to 36.1 tonnes. The centralized vacuum system currently supplies five packaging machines but is designed in such a way that two further packaging machines can be connected. In addition, this has enabled shorter cycle times.

The use of an innovative and energy-efficient vacuum supply was subsidized by the city of Hamburg through the "Companies for Resource Conservation" programme, which confirmed to Block House butchery that it had found the best possible solution for vacuum supply with the centralized vacuum system from Busch.

Maintenance of the centralized vacuum system is performed once a year by a Busch service technician who coordinates his visit beforehand with production engineering. By linking the centralized vacuum system to the operational process control system, it can be constantly monitored and possible irregularities can be immediately recognized. The power consumption is also automatically displayed and documented as a result.

More facts about Block House Fleischerei GmbH

Block House Fleischerei GmbH is a Block Foods AG company. At the modern meat processing plant in Hamburg, Germany, steaks are sliced into portions, cattle is dissected, and burgers and carpaccio are produced (fig. 2). Nearly 100 employees work in the one-shift operation, although burger production is done in two shifts. Some of the products go to the company's own steak restaurant chain, Block House. Most of the 49 restaurants offer their steaks in German cities. But steaks that are aged, cut and packaged at the Block House butchery in Hamburg are also served at Block House Restaurants in Spain, Portugal, Austria and Switzerland. In total, over six million guests are served in these restaurants each year. The majority of the products are delivered to wholesalers, retailers or the gastronomy industry. Customers are mainly in Germany and neighbouring countries.