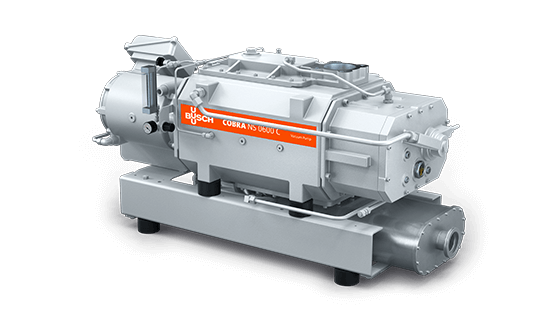

COBRA NS 0070–0600 C

Bombas de vacío de tornillo en seco

Generación de vacío hermética para procesos exigentes

Alto rendimiento

Diseño de tornillo avanzado, tornillos autoequilibrados patentados, perfectas para aplicaciones de recubrimiento, bombeo de helio o fluoración

Eficientes

Coste de propiedad reducido, mantenimiento mínimo, largos intervalos entre servicios, alto tiempo de actividad, eficaz refrigeración por agua

Diseño hermético

Motor integrado, no se contaminan los gases de proceso, herméticas

Especificaciones técnicas

Mercados y aplicaciones

Analítica e I+D

-

Aceleradores de partículas

-

Líneas de luz

-

Recubrimiento

Manipulación de biogás

-

Refinado: adsorción por cambio de presión

Metalurgia

-

Recubrimiento

Procesado de plásticos

-

Disolución

Industria de la energía solar

-

Deposición química de vapor mejorada por plasma (PECVD)

Opciones de diseño

-

ATEX: para uso en zonas con riesgo de explosiones.