Every production team's goal is faster processes, higher performance and shorter cycle times. The only question is how this can be achieved. So you can get the most out of your packaging machine. Busch offers options with frequency controlled and digitally connected vacuum pumps, boosters, buffers and central vacuum systems.

Our solutions to increase your production performance

1. Central vacuum system

How can a central vacuum system help protect the environment? The answer is its high energy efficiency. A central vacuum system is designed to waste as little energy as possible. The less energy wasted, the fewer unnecessary emissions generated. In addition, environmentally friendly measures are sponsored by some states, which reduces investment costs.Get a head start and prepare your system for the climate-friendly vacuum packaging of the future. With the help of a central vacuum system, you can boost your efficiency while doing something good for the environment at the same time.

When pumps, boosters, vacuum buffers, installation and control are precisely matched to your process requirements and work together optimally, nothing stands in the way of your productivity. Discover the best technical solution for vacuum packaging. Let us guide you.

2. Variable speed vacuum pumps

Packaging processes sometimes just need a little more power. After all, peaks in demand are not uncommon in the food industry. Thanks to our Variable Speed Drive (VSD), you can boost the pumping speed of your vacuum pumps by up to 20%. This ensures faster packaging cycles without the need to purchase a new vacuum pump.The demand-driven vacuum pump will only run when the power is actually needed, or will run slower when less power is needed. This means you can save up to 50% energy and protect the climate.

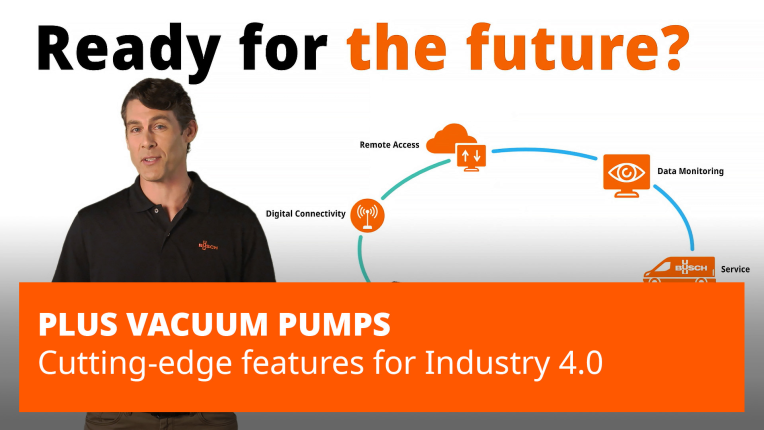

Frequency control and the ability to intelligently network PLUS family pumps are just two examples of the countless advantages of a tailor-made solution from Busch. Watch the video to see all the benefits of the R5 PLUS series.

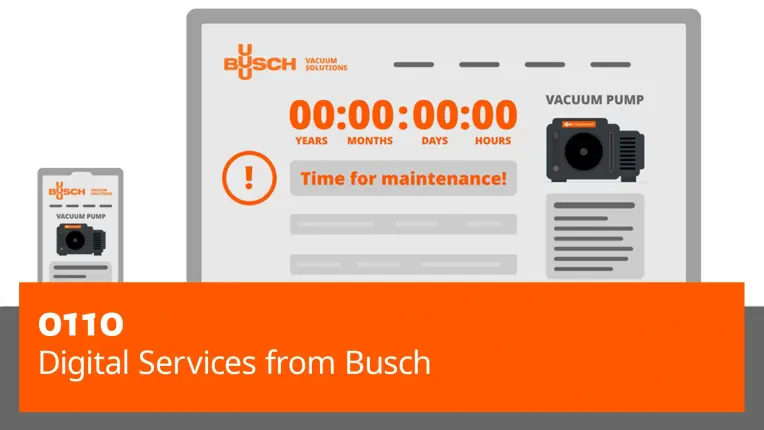

3. Digital Services

The first step towards more climate change mitigation is less energy waste. The intelligent analysis by OTTO – Digital Services provides you with all the data you need to detect and prevent energy waste at an early stage. This is because the IoT system monitors the individual components in real time and indicates when filters or oil should be changed. To optimize your packaging processes and lower your energy consumption.Digital pump documentation with OTTO is also extremely helpful for audits and certifications. Especially for the food industry, it is very easy to export relevant key figures for the IFS7 audit.

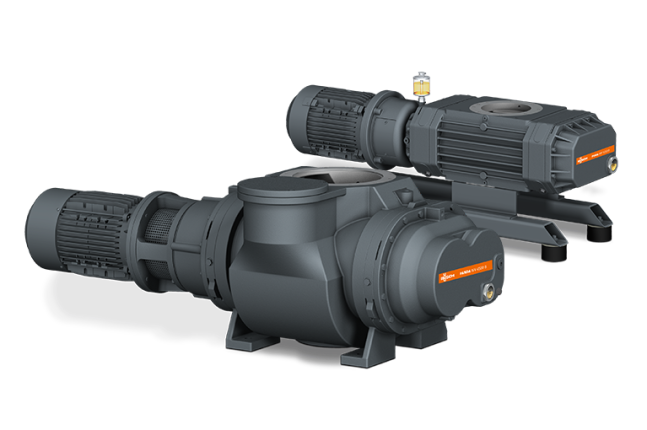

4. Vacuum Booster

The faster, the better. This especially applies to vacuum packaging of foodstuffs. Boosters can boost the volume flow in the critical pressure range, speeding up the pump-down time. This allows the ultimate pressure and pumping speed of each vacuum pump to be increased without having to replace it with a more powerful pump. This means you can achieve higher performance by up to a factor of 10 and package your goods more quickly, making sure they remain even fresher.In addition, a vacuum booster can be installed inside your packaging machine. Use the simple modular system for your update and request support from our service team.