What is vacuum heat treatment?

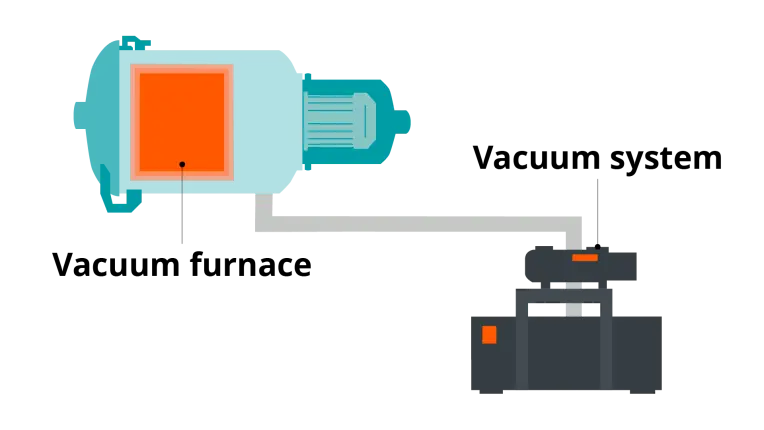

Over time, any material absorbs the air it is exposed to along with the dust and water vapor the air contains. The material reacts chemically, and oxides, nitrides or other undesirable compounds are produced. These may be considered as impurities or contamination.Heating the material under vacuum allows to clean and protect it. This is possible as contaminants will either vaporize when being heated or decompose thermally in the absence of oxygen. The impurities and contaminants disassociated in this way can then be removed from the furnace with the help of vacuum.

The advantage of heat treatment under vacuum is that no costly or flammable gas atmospheres such as Hydrogen or Argon are needed to prevent the material from oxidation when it is heated.