Busch Genuine Vacuum Pump Inlet Filters

Ensure smooth performance. Protect your vacuum pump from unwanted particles. With Busch genuine vacuum inlet filters.

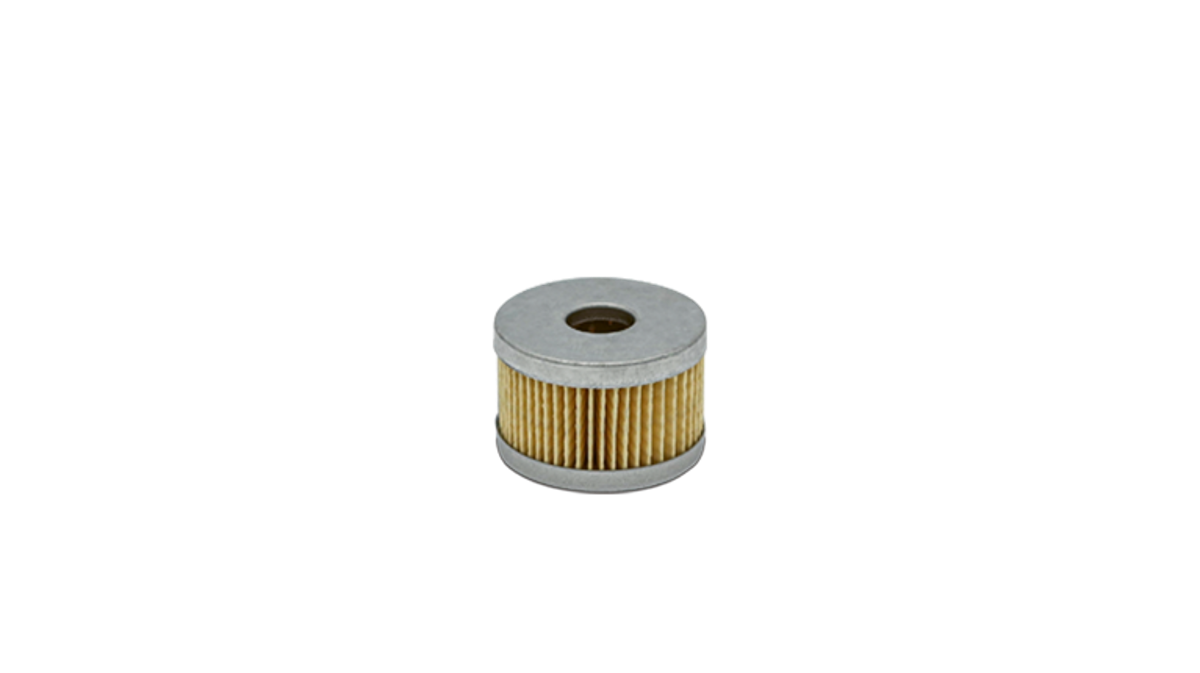

An inlet filter captures any unwanted particles before they are drawn into a vacuum pump or compressor. It is placed at the inlet and is mainly used in dusty or humid applications.

Reduce your maintenance and save money with a Busch genuine inlet filter.

Why Busch Genuine inlet filters?

Cost savings

- Ensure that the process runs smoothly without unplanned downtimes

- Reduce maintenance

Easy maintenance

- Paper cartridges can easily be replaced

- Polyester cartridges can be washed and reused

Increased longevity

- Prevent potential internal damage

- Avoid contamination and abrasion

-

Inlet filter with a paper cartridge for dusty applications, such as pneumatic conveying of powders.

-

Inlet filter with a polyester cartridge for humid applications. These inlet filters can easily be cleaned and reused, and are suitable for food processing applications.

Busch genuine inlet filters are also available for compressors.

To find out which inlet filter fits your needs best, get in touch with our Busch experts.

The right inlet filter for every application

We provide various sizes of inlet filters for our products. Currently, inlet filters are available for R5, MINK, COBRA, SECO, HUCKEPACK, and SAMOS vacuum pumps and compressors.

If you are uncertain about which filter to choose for your process, please contact your local Busch expert.

How to change inlet filters

Paper cartridges must be directly replaced, while polyester cartridges can be washed and reinserted. Do not forget to let the polyester cartridge dry before putting it back. This prevents water droplets and humidity from entering your vacuum pump.

Once the cartridge is placed inside the housing, put the lid back on top of the housing and close the clips.

Three things to look out for when purchasing a vacuum pump inlet filter

1. Use Busch Genuine Parts

Only Busch genuine parts guarantee that your equipment will continue to function optimally and ensure that you maintain your product warranty.

2. Choose the highest quality

Low-quality inlet filters will allow more particles, such as dust and humidity, to enter your vacuum pump or compressor and contaminate your process. Thus, the filters need to be replaced more often, causing an increase in maintenance costs.

3. Select the right size

Make sure that the inlet filter is the right size for your product. We provide standard filters of various sizes for vacuum pumps and compressors.

FAQ

What is the role of a vacuum pump inlet filter?

Inlet filtersare installed at the inlet of vacuum pumps and compressors. Their purpose is to prevent particles from the process, such as dust and debris, from entering the pump and contaminating it.

How do Busch genuine inlet filters work?

The filter is attached to the inlet of the vacuum pump. As the pumped medium is suctioned in, the filter captures any unwanted particles that could damage the pump.

Can I get an inlet filter for my compressor?

Yes, the inlet filters can be used for both vacuum pumps and compressors. To find out which inlet filter fits your needs best, get in touch with our Busch experts.

What types of industrial vacuum pump filters are available?

There are three types of industrial vacuum pump filters:

- Inlet filters are installed at the inlet of a vacuum pump or compressor. Their purpose is to prevent particles, such as dust and debris, from entering the pump and contaminating it.

- Oil filters are used in oil-lubricated rotary vane vacuum pumps. They are located outside of the pump and are connected to the oil mist separator. By removing contaminants from the oil that lubricates the compression chamber, they ensure that it can be reused, remains clean, and retains excellent lubrication and sealing properties.

- Exhaust filters, also known as oil mist filters,are installed upstream of the outlet inside the oil mist separator of oil-lubricated vacuum pumps. They filter the oil mist that is produced during operation, catching and separating it from the pumped medium before it is expelled through the exhaust. This allows the oil particles to coalesce and be recycled back into the system.

Can I use generic vacuum pump filters in my Busch vacuum pump?

You should only use Busch products and parts in your Busch vacuum pump. Third-party inlet filters have not been tested according to our high standards. Only Busch genuine spare parts guarantee the optimum performance of your vacuum pump and keep your warranty valid.

Can I use one type of inlet filter for all Busch vacuum pumps or compressors?

No, the size of your vacuum pump or compressor determines the size of your inlet filter. Likewise, different applications require different types of cartridges.

Does the application play a role in inlet filter choice?

Yes, the type of cartridge used in the inlet filter varies depending on the application. Paper cartridges are used for dusty processes, while polyester cartridges are better suited for humid processes. Moreover, an ATEX-certified pump requires an inlet filter suitable for ATEX processes. We provide inlet filters with antistatic housing and cartridges with either a paper or polyester cartridge. If you are uncertain about which filter to choose for your process, please check with your local Busch expert.

Can I use Busch genuine inlet filters in third-party vacuum pumps?

No. We only design, build and test our parts for Busch vacuum pumps.

What happens if I do not replace the cartridge of my vacuum pump inlet filter regularly?

We recommend inspecting the cartridge once a month. Changing or cleaning the cartridge is a vital component of a regular maintenance schedule. If you do not change your filter regularly, the performance of your vacuum pump will be affected, and energy consumption will be higher.

How do I clean a vacuum pump inlet filter?

Unclip the top of the inlet filter housing, and remove the lid so that the cartridge is visible. Paper cartridges must be directly replaced, while polyester cartridges can be washed and reinserted. Do not forget to let the polyester cartridge dry before putting it back into the house. This prevents water droplets and humidity from entering your vacuum pump. Once the cartridge is placed inside the housing, put the lid back on top of the housing and close the clips.

Who can help me to replace the inlet filter in my vacuum pumps?

Your local Busch service agent will be happy to help. We can carry out the maintenance for you, give you tips and tricks, or offer assistance if you are having any issues. You can also make use of our service contracts: Let us take responsibility for your maintenance while you concentrate on your core business.